Crosslinking master batch which is controllable in crosslinking degree and is used for regenerated polyethylene, and preparation method thereof

A technology of recycled polyethylene and cross-linked masterbatch, which is applied in the field of polymer materials and its preparation, can solve the problems of restricting the recycling of waste PE plastics, the late start of waste plastics, and the decline in physical properties, and achieve good elasticity, reduced viscosity, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

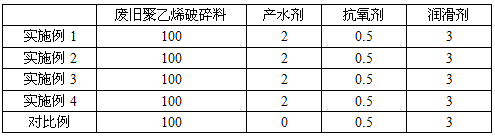

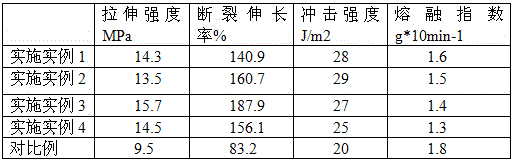

[0033] 1) Preparation of mixed modifier: 3.5 parts of vinyltrimethoxysilane, 0.3 parts of dicumyl peroxide (DCP), 0.2 parts of dibenzoyl peroxide (BPO), 0.5 parts of dibutyltin dilaurate, 30 parts of CPE were stirred and mixed to obtain material 1.

[0034] 2) The rest of the raw materials were weighed according to the data corresponding to Example 1 in Table 1 and added to a high-speed mixer for medium-speed stirring and mixing to obtain material 2.

[0035] 3) Add material 1 and material 2 together into a high-speed mixer for medium-speed stirring and mixing to obtain a premix; put the premix into a twin-screw extruder to heat, melt, extrude and plasticize to obtain a semi-finished product. The working conditions are: the temperature is 180-210°C, the screw speed is 300-400r / min; then the semi-finished product is drawn, cooled, dried, and granulated, and the temperature of the cooling water is kept at 45-55°C during the cooling process. A cross-linked masterbatch with a con...

Embodiment 2

[0037] 1) Preparation of mixed modifier: 2 parts of vinyltrimethoxysilane, 1.5 parts of KU-550, 0.3 parts of dicumyl peroxide (DCP), 0.2 parts of dibenzoyl peroxide (BPO), dilauric acid dilaurate 0.5 part of butyltin and 30 parts of CPE were stirred and mixed to obtain material 1.

[0038] 2) The rest of the raw materials were weighed according to the data corresponding to Example 2 in Table 1 and added to a high-speed mixer for medium-speed stirring and mixing to obtain material 2.

[0039] 3) Add material 1 and material 2 together into a high-speed mixer for medium-speed stirring and mixing to obtain a premix; put the premix into a twin-screw extruder to heat, melt, extrude and plasticize to obtain a semi-finished product. The working conditions are: the temperature is 180-210°C, the screw speed is 300-400r / min; then the semi-finished product is drawn, cooled, dried, and granulated, and the temperature of the cooling water is kept at 45-55°C during the cooling process. A cr...

Embodiment 3

[0041] 1) Preparation of mixed modifier: 2 parts of vinyltrimethoxysilane, 1.5 parts of KU-550, 0.5 part of dicumyl peroxide (DCP), 0.5 part of dibutyltin dilaurate, and 30 parts of CPE were stirred and mixed to prepare Material 1.

[0042] 2) The rest of the raw materials were weighed according to the data corresponding to Example 3 in Table 1 and added to a high-speed mixer for medium-speed stirring and mixing to obtain material 2.

[0043] 3) Add material 1 and material 2 together into a high-speed mixer for medium-speed stirring and mixing to obtain a premix; put the premix into a twin-screw extruder to heat, melt, extrude and plasticize to obtain a semi-finished product, The working conditions are: the temperature is 180-210°C, the screw speed is 300-400r / min; then the semi-finished product is drawn, cooled, dried and granulated, and the temperature of the cooling water is kept at 45-55°C during the cooling process. Finally, a cross-linked masterbatch with a controllable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com