Fungal hypha total DNA (deoxyribonucleic acid) extracting solution and method for extracting fungal hypha total DNA

A technology for extracting liquid and fungi, applied in the field of extracting the total DNA of fungal mycelium and extracting the total DNA of fungal mycelium, can solve the problems of long operation time, low efficiency, no wall removal effect, etc., and simplify the operation steps. , the effect of reducing operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

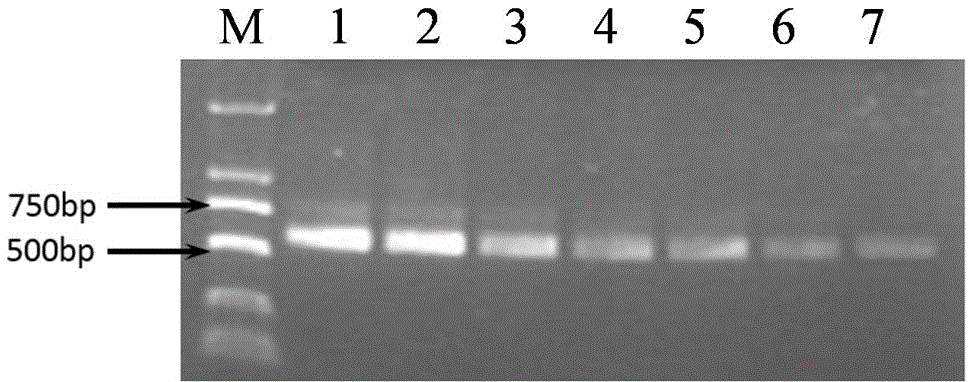

Image

Examples

Embodiment 1

[0032] The extract I: including 200mM Tris-HCl, 10mMC 12 The aqueous solution of fatty alcohol ether ammonium sulfate and 200mM sodium chloride has a pH value of 8.0;

[0033] The extract II: including 200mM Tris-HCl and 1ppm cationic polyacrylamide, its pH value is 8.0.

[0034] (1) Collect the fungal mycelium of powdery mildew;

[0035] (2) Put 1 mg of fungal mycelium in 500 microliters of extract I, and mix it upside down;

[0036] (3) Freeze and thaw twice at minus 196°C and 60°C respectively, that is, freeze at minus 196°C and thaw at 60°C;

[0037] (4) Add 50 microliters of extract solution II, invert and mix well, and let stand for 2 minutes;

[0038] (5) Centrifuge at 10,000 rpm for 5 minutes to remove insoluble matter and obtain a supernatant containing fungal DNA.

Embodiment 2

[0040] Extract I: including 150mM sodium phosphate, 5mMC 15 The aqueous solution of fatty alcohol ether ammonium sulfate and 100mM sodium chloride has a pH value of 7.8;

[0041] Extract solution II: including 150mM sodium phosphate and 3ppm cationic polyacrylamide, its pH value is 7.8.

[0042] (1) Collect the fungal mycelium of powdery mildew;

[0043] (2) Put 1 mg of fungal mycelium in 500 microliters of extract I, and mix it upside down;

[0044] (3) Freeze and thaw three times at minus 80°C and 50°C respectively, that is, freeze at minus 80°C and thaw at 50°C;

[0045] (4) Add 75 microliters of extract solution II, invert and mix well, and let stand for 2 minutes;

[0046] (5) Centrifuge at 12000rpm for 3 minutes to remove insoluble matter and obtain the supernatant containing fungal DNA.

[0047] (6) Add an appropriate amount of isopropanol, place at minus 30°C for 30 minutes, centrifuge at 12,000 rpm for 10 minutes, and then dissolve in an appropriate amount of TE b...

Embodiment 3

[0049] Extraction solution I: including 100mM disodium hydrogen phosphate, 5mMC 15 The aqueous solution of fatty alcohol ether ammonium sulfate and 100mM sodium chloride has a pH value of 8.2;

[0050] Extract solution II: including 100 mM disodium hydrogen phosphate and 3 ppm cationic polyacrylamide, and its pH value is 8.2.

[0051] (1) Collect the fungal mycelium of powdery mildew;

[0052] (2) Put 1 mg of fungal mycelium in 500 microliters of extract I, and mix it upside down;

[0053] (3) Freeze and thaw twice at minus 50°C and 50°C respectively, that is, freeze at minus 50°C and thaw at 50°C;

[0054] (4) Add 125 microliters of extract solution II, invert and mix well, and let stand for 2 minutes;

[0055] (5) Centrifuge at 12,000 rpm for 5 minutes to remove insoluble matter and obtain a supernatant containing fungal DNA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com