Precise micropressure control and comprehensive waste gas processing device suitable for atmosphere kiln

A comprehensive treatment and precise control technology, applied in the direction of waste heat treatment, charging treatment type, furnace, etc., can solve problems such as kiln pressure instability, and achieve the effect of avoiding fluctuations in product quality, small fluctuations in furnace pressure, and simple waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

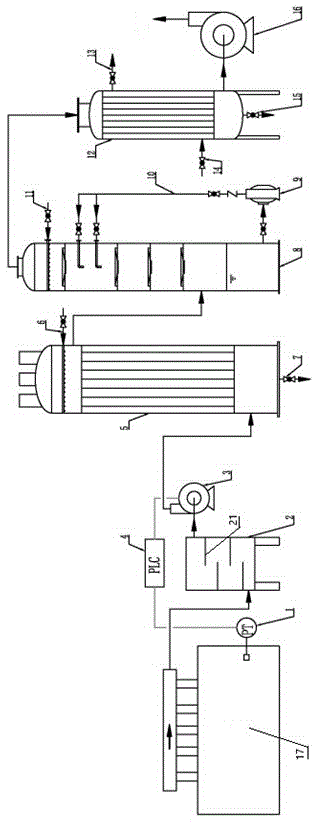

[0019] refer to figure 1 The one shown is suitable for precise micro-pressure control and exhaust gas comprehensive treatment of atmosphere kilns, including kiln 17, micro-pressure control system and exhaust gas comprehensive treatment system.

[0020] The micro-pressure control system includes a differential pressure micro-pressure transmitter 1, a buffer tank 2, a relay fan 3, and a programmable logic controller 4 (PLC). The differential pressure micro-pressure transmitter 1 is used to detect the pressure of the kiln 17 (several 10 Pa), installed on the kiln 17, which can well respond to the furnace pressure and is not easy to block the temperature zone; the buffer tank 2 is used to stabilize the pressure of the exhaust gas of the kiln 17, and several layers of baffles 21 are arranged inside it to increase the pressure of the gas in the furnace. The residence time inside it is more conducive to voltage stabilization; the relay fan 3 is used for the exhaust gas extraction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com