A kind of cobalt selenide/nitrogen-doped carbon composite material and its preparation method and application

A nitrogen-doped carbon, composite material technology, applied in nanotechnology for materials and surface science, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve problems such as reduced stability and achieve excellent electrical conductivity , good repeatability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

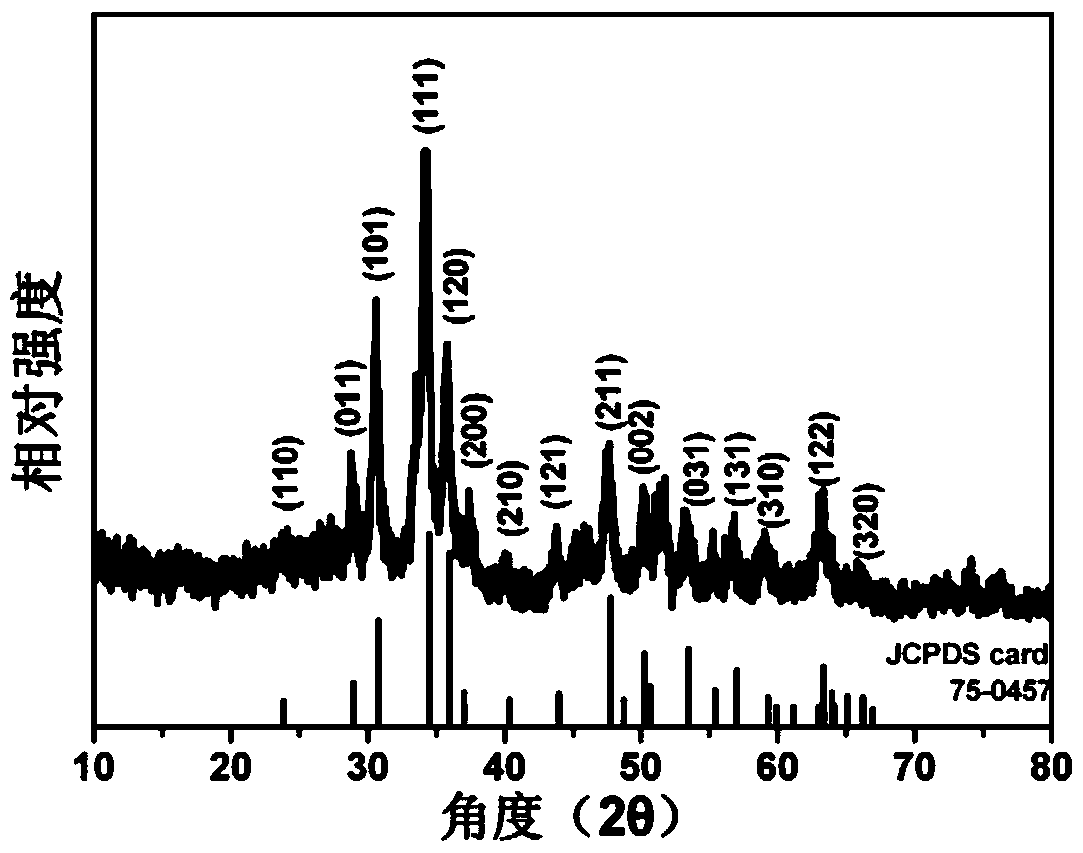

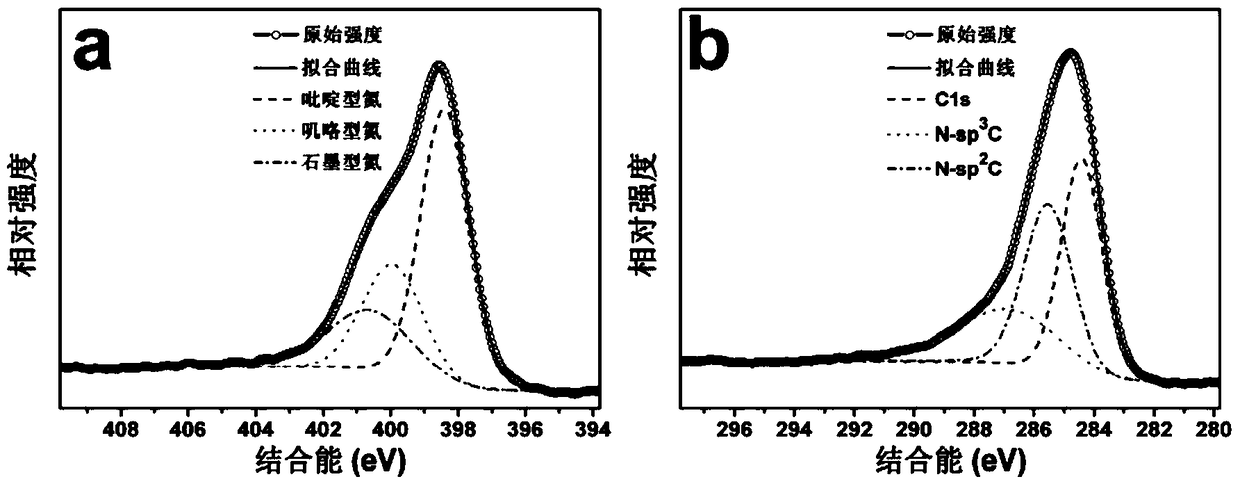

[0031] Double-shell cobalt selenide (CoSe 2 ) / Nitrogen-doped carbon composites

[0032] The cobalt nitrate hexahydrate of 4mmol is joined in the 200mL methanol that contains 20mmol dimethylimidazole, after mixing uniformly, leave standstill for 24 hours; The precipitate ZIF-67 obtained is centrifuged and dried, and the dry product and selenium powder are mixed at 1: The mass ratio of 1 is mixed; the resulting mixture is calcined at a temperature of 600 degrees Celsius for 4 hours under an argon atmosphere to obtain cobalt selenide (CoSe) with a double-shell structure. 2 ) / nitrogen-doped carbon composites.

[0033] The phase of the product was characterized by Rigaku D / max 2500 X-ray diffractometer, the elements contained in the product were analyzed by ESCALAB 250Xi X-ray photoelectron spectrometer from Thermo Fisher Scientific, and the product was analyzed by Nova NanoSEM230 scanning electron microscope. The morphology was characterized, and the internal structure of the pr...

Embodiment 2

[0040] Cobalt selenide (CoSe 2 ) / Nitrogen-doped carbon composites

[0041] Add 4mmol of cobalt nitrate hexahydrate to 200mL of methanol containing 20mmol of dimethylimidazole, mix well and let stand for 24 hours; centrifuge and dry the resulting precipitate, and dry the product and selenium powder at a mass ratio of 1:1 than mixing; the resulting mixture was calcined at a temperature of 300 degrees Celsius for 4 hours under an argon atmosphere to obtain cobalt selenide (CoSe 2 ) / nitrogen-doped carbon composites.

Embodiment 3

[0043] Preparation of Large Size Cobalt Selenide (CoSe) / Nitrogen Doped Carbon Composite

[0044] Add 1 mmol of cobalt nitrate hexahydrate to 100 mL of methanol containing 5 mmol of dimethylimidazole, mix well and let stand for 24 hours; centrifuge and dry the obtained precipitate, and mix the dried product and selenium powder at a mass ratio of 1:1 ratio mixing; the resulting mixture was calcined at a temperature of 600 degrees Celsius for 4 hours under an argon atmosphere to obtain a cobalt selenide (CoSe) / nitrogen-doped carbon composite material.

[0045] The phase of the product was characterized by Rigaku D / max 2500 X-ray diffractometer, and the morphology of the product was characterized by NovaNanoSEM230 scanning electron microscope.

[0046] Image 6 Be the X-ray powder diffraction figure of the product of embodiment 3, the result shows that product is a cobalt selenide phase;

[0047] Figure 7 It is the SEM picture of the product of Example 3, it can be seen that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com