Nickel selenide/graphene sodium ion battery composite negative material as well as preparation method and application thereof

A technology of sodium ion battery and negative electrode material, applied in the field of electrochemistry, can solve the problems of poor electrical conductivity, too fast specific capacity decay, etc., and achieve the effects of low cost, improved structural stability, and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

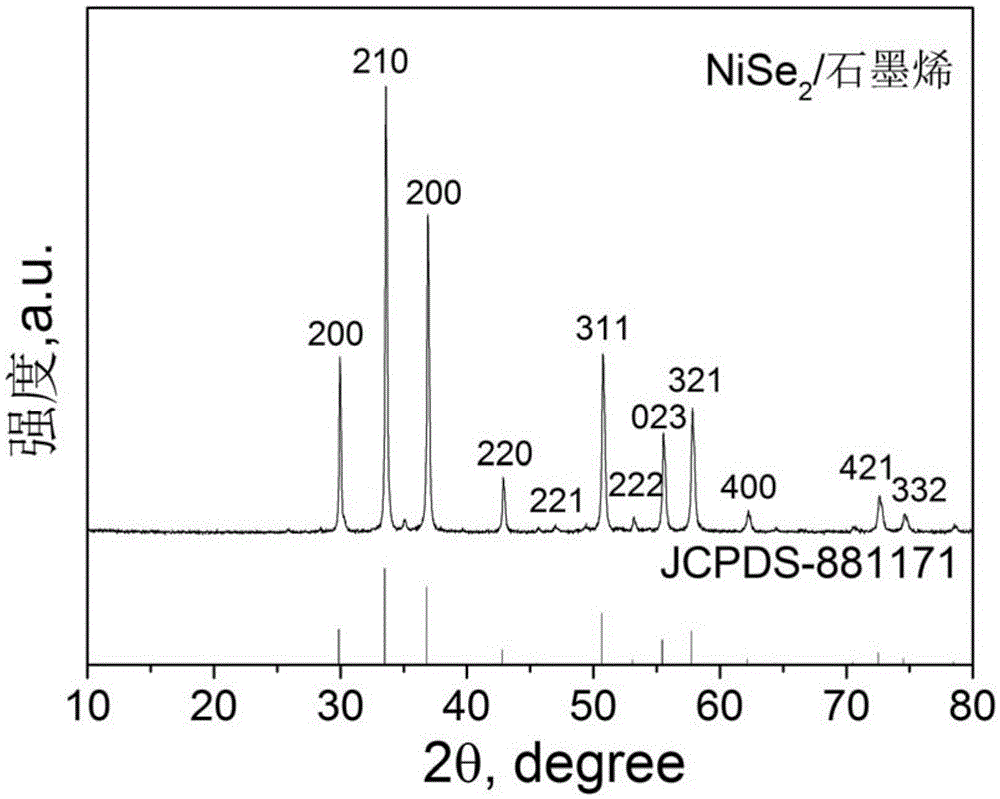

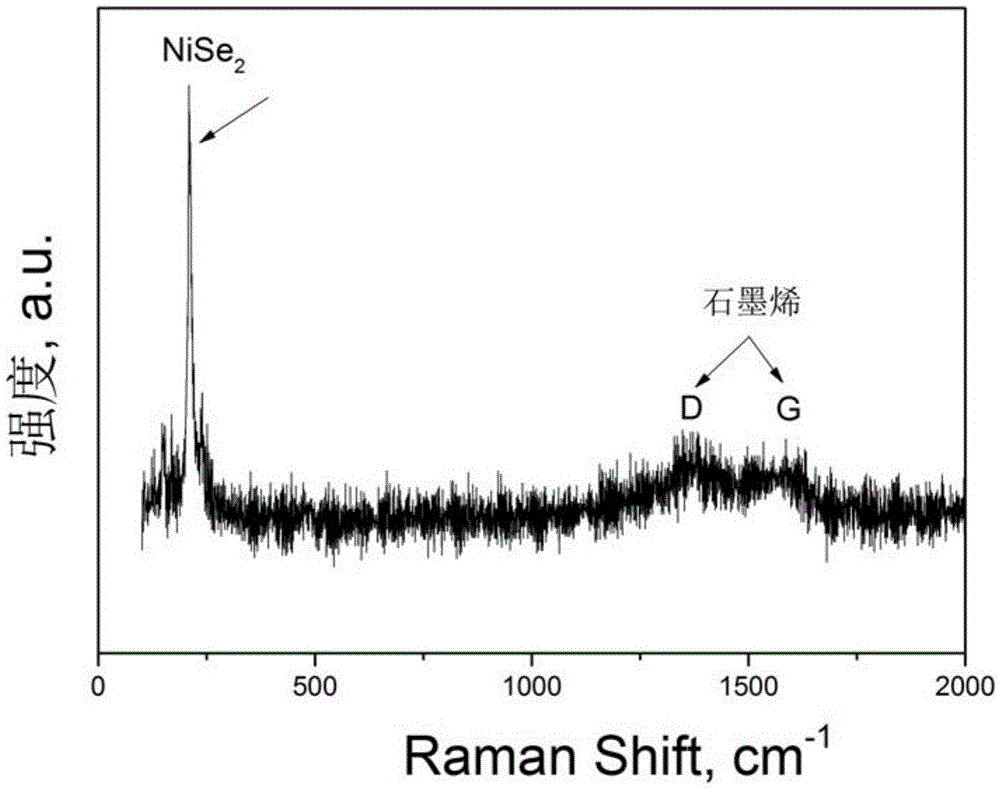

[0030] (1) Weigh 0.586g of nickel nitrate (Ni(NO 3 ) 2 6H2O) and 0.1 g of graphene were added to 80 ml of deionized water, and after ultrasonication for 2 hours, a dispersion liquid was obtained. The dispersion obtained above was uniformly mixed with 0.32 g of selenium powder, and subjected to a hydrothermal reaction at 200° C. for 20 h. The hydrothermal reaction product is separated from the solid and liquid, and the obtained solid is washed three times with water and alcohol respectively, and dried in a vacuum oven at 60°C to obtain nickel selenide / graphene sodium with a nickel selenide content of 76.91wt%. Composite anode materials for ion batteries. X-ray powder diffraction (XRD) analysis shows that the obtained product is pure nickel selenide without any other impurity phases and high crystallinity (such as figure 1 shown). It can be seen from the Raman spectrum that at a displacement of 1350cm -1 D peaks appear on the left and right, with a displacement of 1600cm -...

Embodiment 2

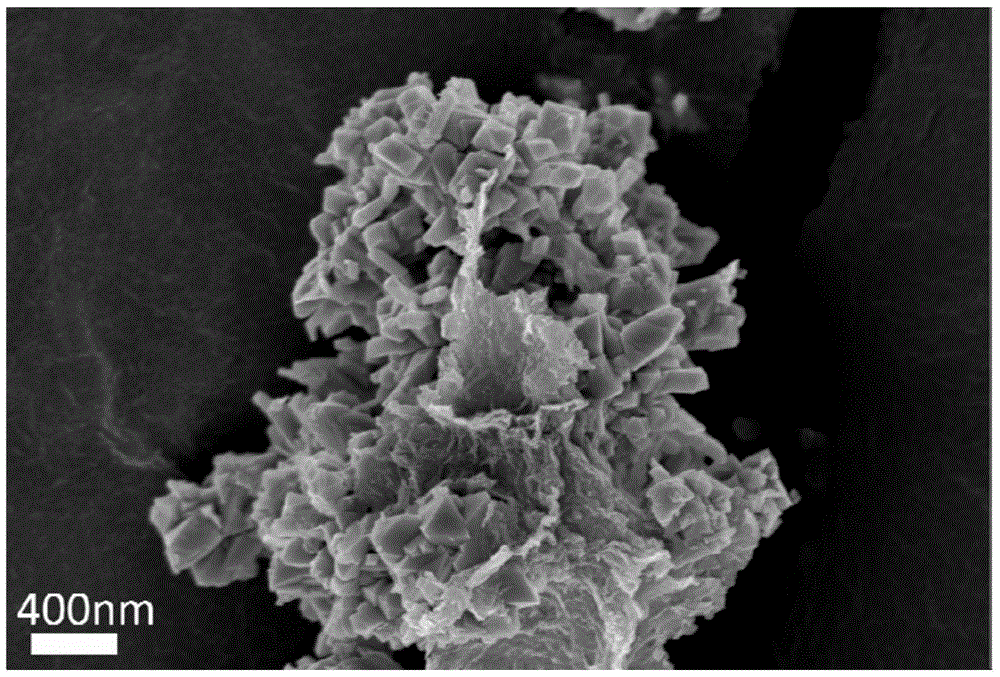

[0033] (1) Weigh 0.526g of nickel sulfate (NiSO 4 ·6H 2 O) 0.15 g of graphene was added to 80 ml of pure ethanol, and ultrasonicated for 5 hours to obtain a dispersion. The dispersion obtained above was uniformly mixed with 0.32 g of selenium powder, and subjected to hydrothermal reaction at 180° C. for 30 h. The hydrothermal reaction product was separated from solid to liquid, and the obtained solid was washed three times with water and alcohol, and dried in a vacuum oven at 90°C to obtain a nickel selenide / graphene sodium ion battery with a nickel selenide content of 65.36 wt%. Composite anode materials. Further XRD and Raman spectrogram analysis showed that the composition of the prepared nickel selenide / graphene composite material was similar to that of Example 1, consisting of nickel selenide and graphene. It can be seen from the SEM image that graphene is uniformly wrapped on the surface of octahedral nano-nickel selenide particles, with a particle size of 200-300nm. ...

Embodiment 3

[0036] 1) Weigh 0.586g of nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) 0.1 g of graphene was added to 80 ml of pure methanol, and after ultrasonication for 1 hour, a dispersion was obtained. The dispersion obtained above was uniformly mixed with 0.44 g of selenium dioxide, and subjected to a hydrothermal reaction at a temperature of 160° C. for 40 h. The hydrothermal reaction product was separated from solid to liquid, and the obtained solid was washed three times with water and alcohol, and dried in a vacuum oven at 60°C to obtain a nickel selenide / graphene sodium ion battery with a nickel selenide content of 76.91wt%. Composite anode materials. Further analysis of (XRD) spectrum and Raman spectrum shows that the result of the prepared nickel selenide / graphene composite material is similar to that of Example 1, and is composed of nickel selenide and graphene. It can be seen from the SEM image that graphene is uniformly wrapped on the surface of octahedral nano-nickel selenide par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com