Platinum supported nitrogen-doped molybdenum disulfide photocatalyst and preparation method thereof

A technology of molybdenum disulfide and photocatalyst, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of molybdenum disulfide and hydrogen generation, etc. Achieve and stabilize hydrogen production capacity, good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

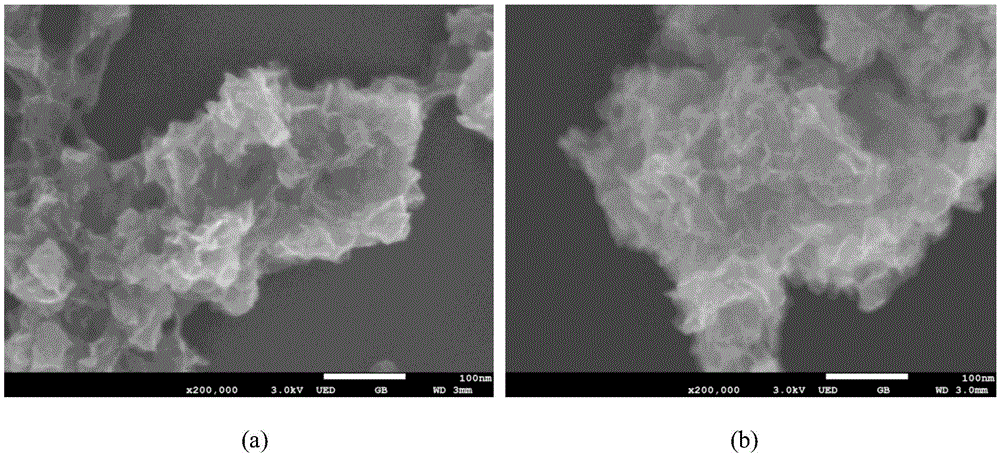

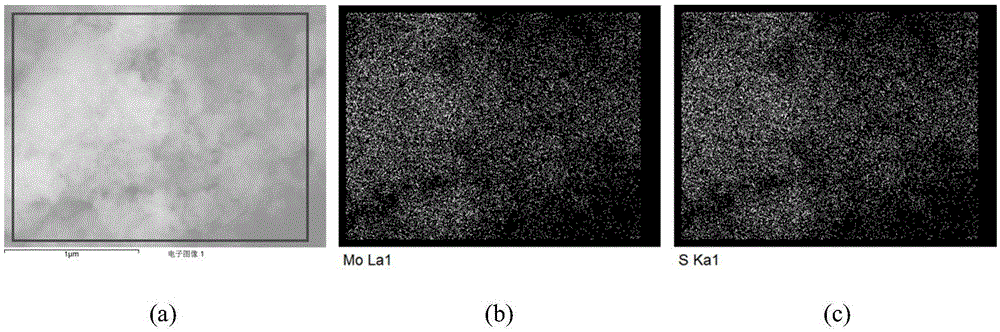

[0039] Step 1: at room temperature, 2.72g of sodium molybdate dihydrate (NaMoO 4 2H 2 (2) and 5.44g thioacetamide were stirred and dissolved in 60mL deionized water successively, and the resulting mixed solution (the concentration of sodium molybdate dihydrate was 45.3g / L, and the concentration of thioacetamide was 90.7g / L) at room temperature After stirring for 6 hours, it was transferred to a polytetrafluoroethylene-lined hydrothermal kettle (filling degree 60%) for hydrothermal reaction, and crystallized at 200 ° C for 24 hours; after the hydrothermal kettle was lowered to room temperature, the resulting black precipitate Wash with deionized water and ethanol and dry in vacuum at 50°C for 24h to obtain black powdery molybdenum disulfide nanosheets;

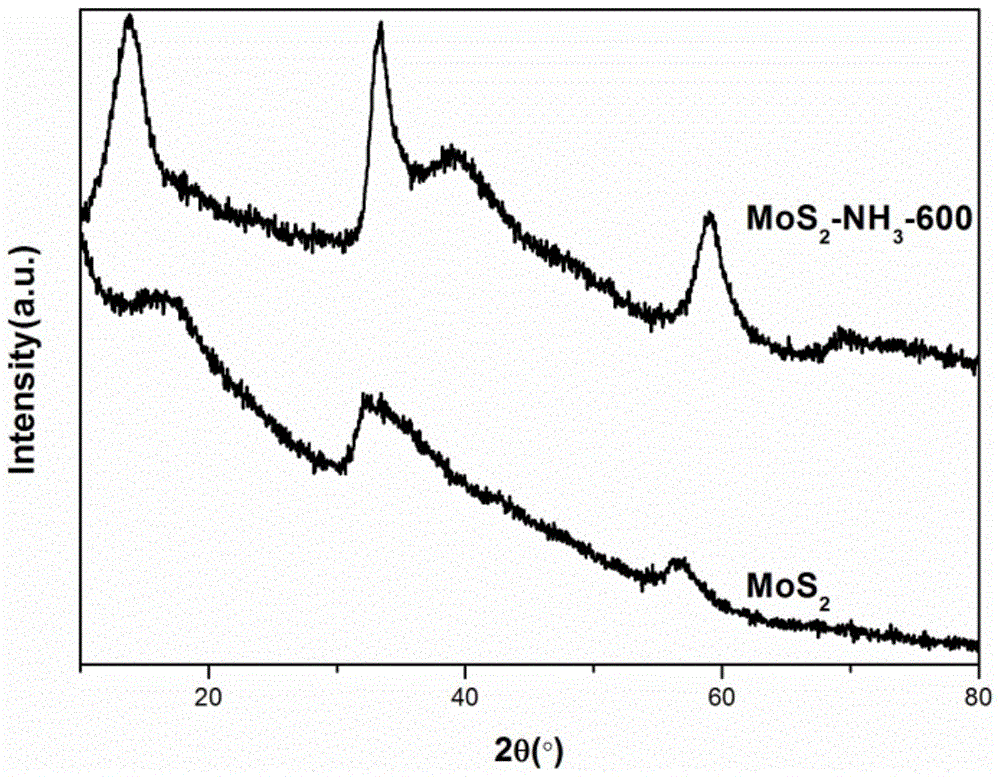

[0040] Step 2: Get the 0.3g molybdenum disulfide nanosheet powder obtained in step 1 and place it in a high-temperature tube furnace for high-temperature treatment. In the high-temperature treatment process, keep the 100mL / min...

Embodiment 5

[0047] Step 1: At room temperature, dihydrate sodium molybdate (NaMoO 4 2H 2 (2) and thioacetamide are stirred and dissolved in deionized water successively, and the resulting mixed solution (the concentration of sodium molybdate dihydrate is 40g / L, and the concentration of thioacetamide is 40g / L) is transferred to after stirring at room temperature for 6h Carry out hydrothermal reaction in the hydrothermal still (filling degree 55%) that polytetrafluoroethylene liner is housed, crystallize 48h at 205 ℃; Washing with ethanol and drying in vacuum at 60°C for 42 hours to obtain black powdery molybdenum disulfide nanosheets;

[0048] Step 2: Get the 0.3g molybdenum disulfide nanosheet powder obtained in step 1 and place it in a high-temperature tube furnace for high-temperature treatment. In the high-temperature treatment process, the tube furnace maintains an ammonia atmosphere of 110mL / min, and the high-temperature treatment temperature is 450°C, the treatment time is 1.5h; w...

Embodiment 6

[0054] Step 1: At room temperature, dihydrate sodium molybdate (NaMoO 4 2H 2 (2) and thioacetamide are stirred and dissolved in deionized water successively, and the resulting mixed solution (the concentration of sodium molybdate dihydrate is 50g / L, and the concentration of thioacetamide is 150g / L) is transferred to after stirring at room temperature for 6h Carry out hydrothermal reaction in the hydrothermal still (filling degree 65%) that polytetrafluoroethylene liner is housed, crystallize 42h at 210 ℃; Washing with ethanol and drying in vacuum at 70°C for 36 hours to obtain black powdery molybdenum disulfide nanosheets;

[0055] Step 2: Get the 0.3g molybdenum disulfide nanosheet powder obtained in step 1 and place it in a high-temperature tube furnace for high-temperature treatment. In the high-temperature treatment process, keep 120mL / min of ammonia gas in the tube furnace. The high-temperature treatment temperature is 550°C, the treatment time is 1.2h; when the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com