Method for preparing metal lead powder through vacuum carbothermal reduction

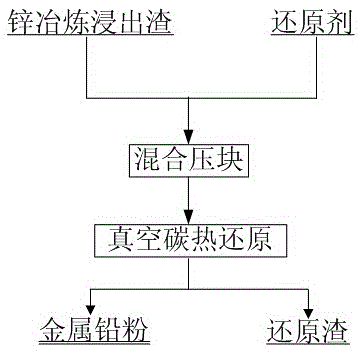

A metal lead and carbon heat technology, applied in the direction of improving process efficiency, can solve the problems of consumption and processing costs, achieve stable and reliable quality, shorten the process flow, and improve the utilization level of waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) According to the mass ratio of 5:1, take 100g of zinc smelting leaching slag, the main component is lead sulfate, containing 50.73% lead, the reducing agent is 20g of activated carbon, and the leaching slag is crushed and mixed evenly with activated carbon to obtain a mixture.

[0024] (2) Compress the mixture into a cylindrical block on a tablet press.

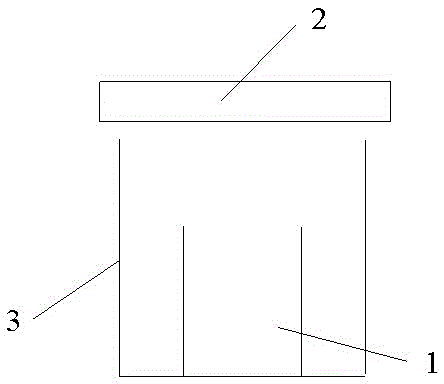

[0025] (3) Put the block material into the high temperature resistant crucible, open the top of the crucible, then put it into the vacuum furnace, and set the furnace cover with a condensation plate above the crucible in the furnace. After covering the furnace cover, start the vacuum furnace, heat up to 500°C at a heating rate of 5°C / min, hold for 8 hours, and control the pressure in the vacuum furnace at 1-5Pa.

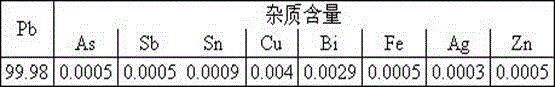

[0026] (4) After the reduction reaction is completed, cool down, start the furnace and take the material, and obtain the product metal lead powder on the condensing plate, the purity is 99.98%, and the co...

Embodiment 2

[0030] (1) According to the mass ratio of 20:1, take 100g of zinc smelting leaching slag, the main component is lead sulfate, containing 55.36% lead, and 5g of reducing agent charcoal. After crushing the leaching slag, mix it with charcoal powder evenly.

[0031] (2) Compress the mixture into a cylindrical block on a tablet press.

[0032] (3) Put the block material into the high temperature resistant crucible, open the top of the crucible, then put it into the vacuum furnace, and set the furnace cover with a condensation plate above the crucible in the furnace. After covering the furnace cover, start the vacuum furnace, heat up to 650°C at a heating rate of 10°C / min, hold for 5 hours, and control the pressure in the vacuum furnace at 5-10Pa.

[0033] (4) After the reduction reaction is finished, cool down, start the furnace to take the material, and obtain the product metal lead powder on the condensing plate, the purity is 99.991%. 0.22%, bismuth 3.51%, copper 4.23%, antimo...

Embodiment 3

[0037] (1) According to the mass ratio of 10:1, take 100g of zinc smelting leaching slag, the main component is lead sulfate, containing 64.83% lead, and the reducing agent is 10g of coal, and the two are crushed and mixed evenly to obtain a mixture.

[0038] (2) Compress the mixture into a cylindrical block on a tablet press.

[0039] (3) Put the block material into the high temperature resistant crucible, open the top of the crucible, then put it into the vacuum furnace, and set the furnace cover with a condensation plate above the crucible in the furnace. After covering the furnace cover, start the vacuum furnace, heat up to 1000°C at a heating rate of 20°C / min, hold for 1 hour, and control the pressure in the vacuum furnace at 60-100Pa.

[0040] (4) After the reduction reaction is completed, cool down, start the furnace and take the material, and obtain the product metal lead powder on the condensing plate, the purity is 99.995%, and the composition is shown in Table 3; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com