Method for preparing 1,4-butynediol

A technology of butynediol and acetylene, applied in the production field of organic chemical products, can solve the problem of frequent replacement of catalysts and filter bags, achieve the effects of good mechanical strength and anti-pollution performance, avoid losses, and ensure continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

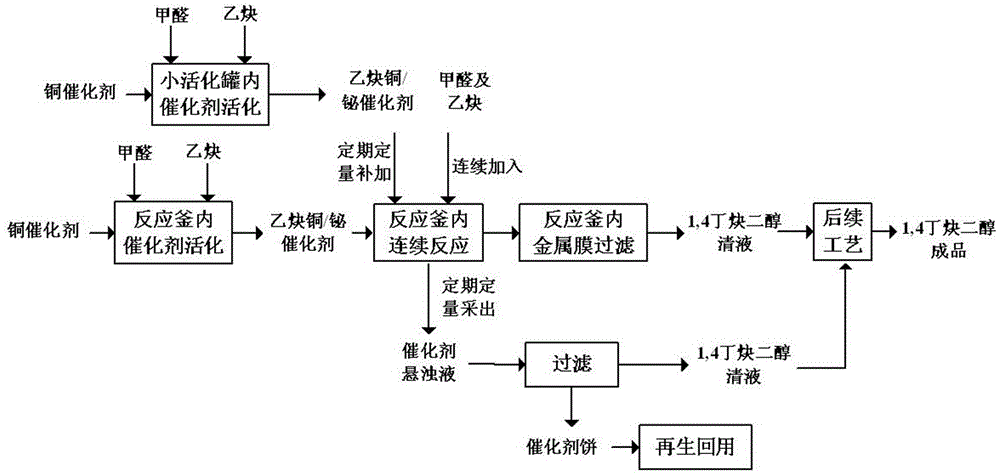

[0024] The preparation method of 1,4-butynediol, process flow diagram is by figure 1 shown. The preparation method steps are as follows:

[0025] (1) The catalyst is activated for the first time

[0026] A reactor with a built-in metal membrane filter was used, and it was started for the first time, and 6t of copper catalyst (CuO-Bi 2 o 3 , Cu content is about 20%, Bi content is about 3%) and 27t formaldehyde solution (mass fraction 28%), at a temperature of 80°C, 0.13MPa acetylene gas is passed through for activation. After 9h, the active component copper is converted into Copper acetylene to obtain a copper acetylene / bismuth catalyst;

[0027] (2) Continuous reaction

[0028] Control the pressure in the reactor to 0.08MPa, the temperature to 90°C, continuously feed acetylene gas into the reactor, the acetylene space velocity is 4min-1, continuously add formaldehyde solution (mass fraction 28%), in the reaction medium, acetylene copper / bismuth The catalyst content is 10...

Embodiment 2

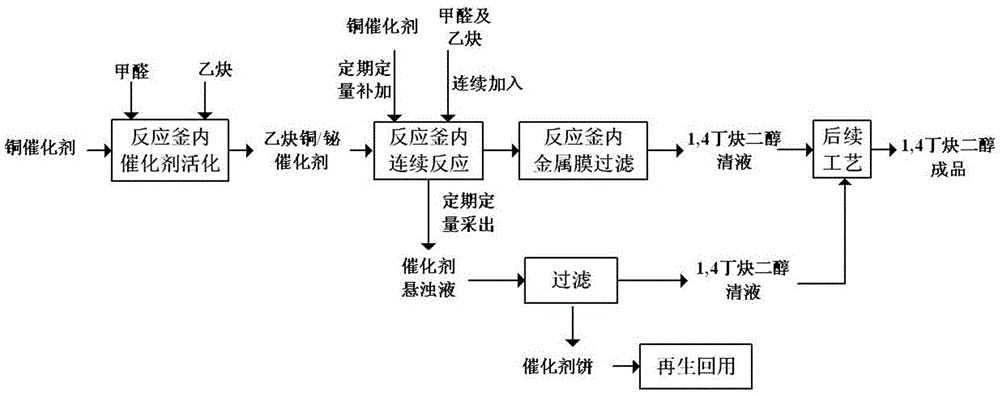

[0036] The preparation method of 1,4-butynediol, process flow diagram is by figure 2 shown. The preparation steps are as follows:

[0037] (1) The catalyst is activated for the first time

[0038] A reactor with a built-in metal membrane filter is used, and the first start-up, 12t copper catalyst (CuO-Bi 2 o 3 , Cu content is about 20%, Bi content is about 2.5%) and 50t formaldehyde solution (mass fraction 33%), at a temperature of 70 ° C, 0.15 MPa of acetylene gas is passed through for activation. After 10 hours, the active component copper is converted into Copper acetylene to obtain a copper acetylene / bismuth catalyst;

[0039] (2) Continuous reaction

[0040] Control the pressure in the reactor to 0.10MPa, the temperature to 85°C, continuously feed acetylene gas into the reactor, the acetylene space velocity is 4.5min-1, continuously add formaldehyde solution (mass fraction 33%), in the reaction medium, copper acetylene / bismuth catalyst content is 9%, and acetylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com