Kasugamycin fermentation medium and fermentation method thereof

A fermentation medium and a technology for kasugamycin, which is applied in the field of microbial fermentation, can solve the problems of difficult foam inhibition, restricting kasugamycin fermentation yield, etc. The effect of transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

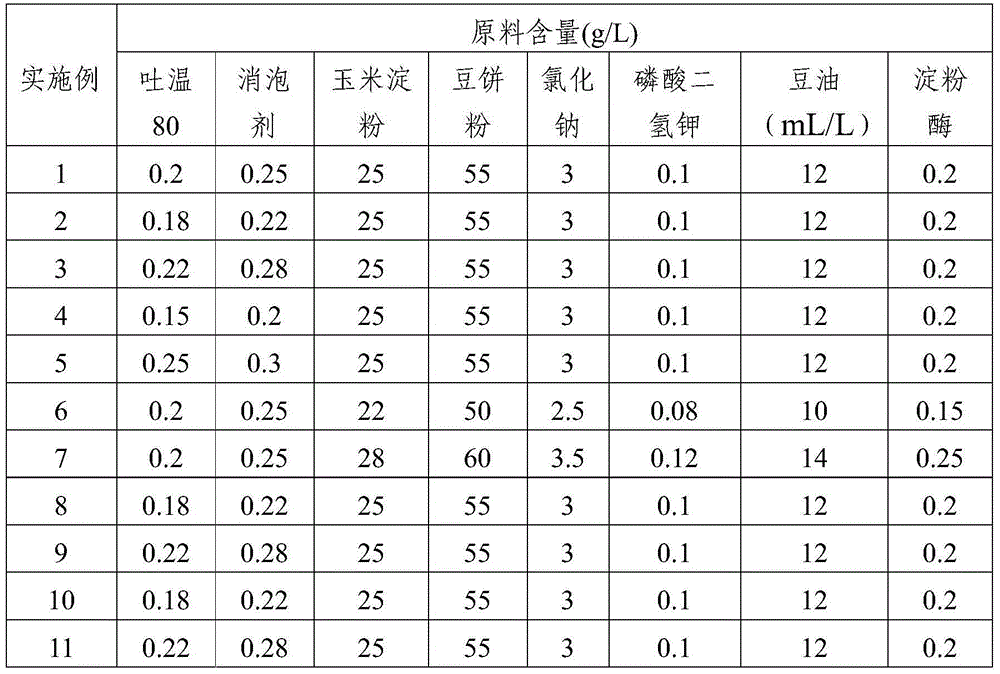

[0039] Examples 1-11 are used to illustrate the fermentation medium provided by the present invention.

[0040] Prepare fermentation medium according to the proportioning mode of each raw material given in Table 1 according to the following steps:

[0041] Mix cornstarch, bean cake powder, sodium chloride, potassium dihydrogen phosphate, soybean oil, amylase and water in proportion, then add defoamer and mix to obtain a mixture, then add Tween 80 to the mixture and mix to adjust the pH value Fermentation media 1-11 were obtained to 7.0.

[0042] Wherein the antifoaming agent used among the embodiment 1-7 is glycerol polypropylene oxide.

[0043] The defoamer used in Examples 8 and 9 was simethicone.

[0044] The defoamer used in Examples 10 and 11 is glycerol polyoxypropylene polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com