A method for controlling the directional growth of gypsum hemihydrate single crystal

A hemihydrate gypsum, directional growth technology, applied in the field of gypsum, can solve the problems of easy volatilization, uncontrollable shape, and easy pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific embodiments.

[0015] A. Raw material pretreatment:

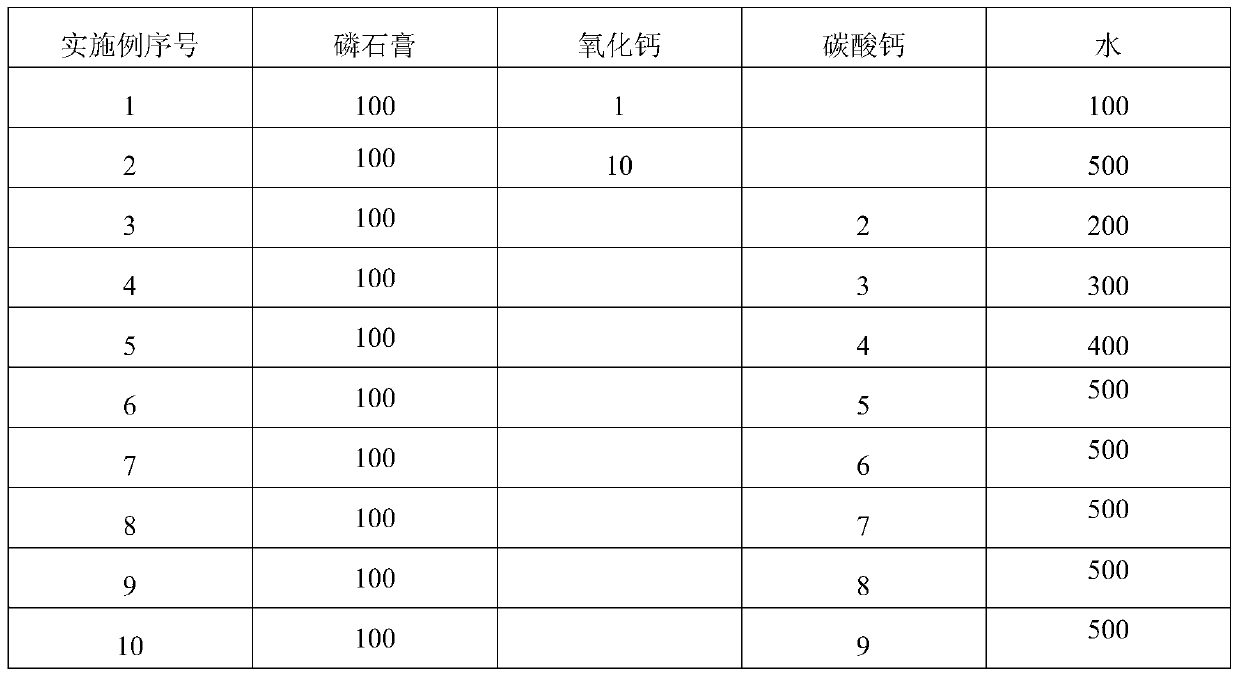

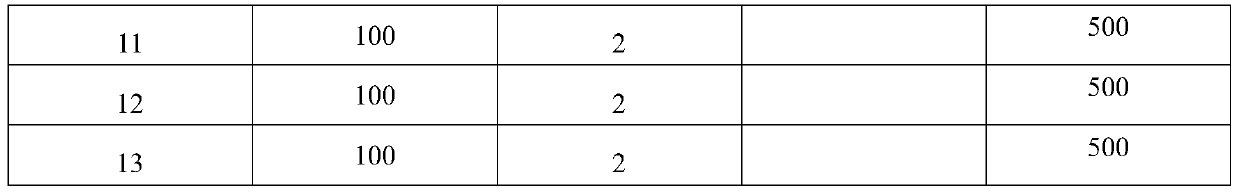

[0016] Table 1 lists the amounts of various raw materials used in the pretreatment of the raw materials in the 13 examples numbered 1-13: According to the different examples in Table 1, determine the amount of acidity regulator (calcium oxide, calcium carbonate) and water added, and After aging for 24 hours, the phosphogypsum raw material is pretreated.

[0017] Table 1 Raw material pretreatment (unit: g)

[0018]

[0019]

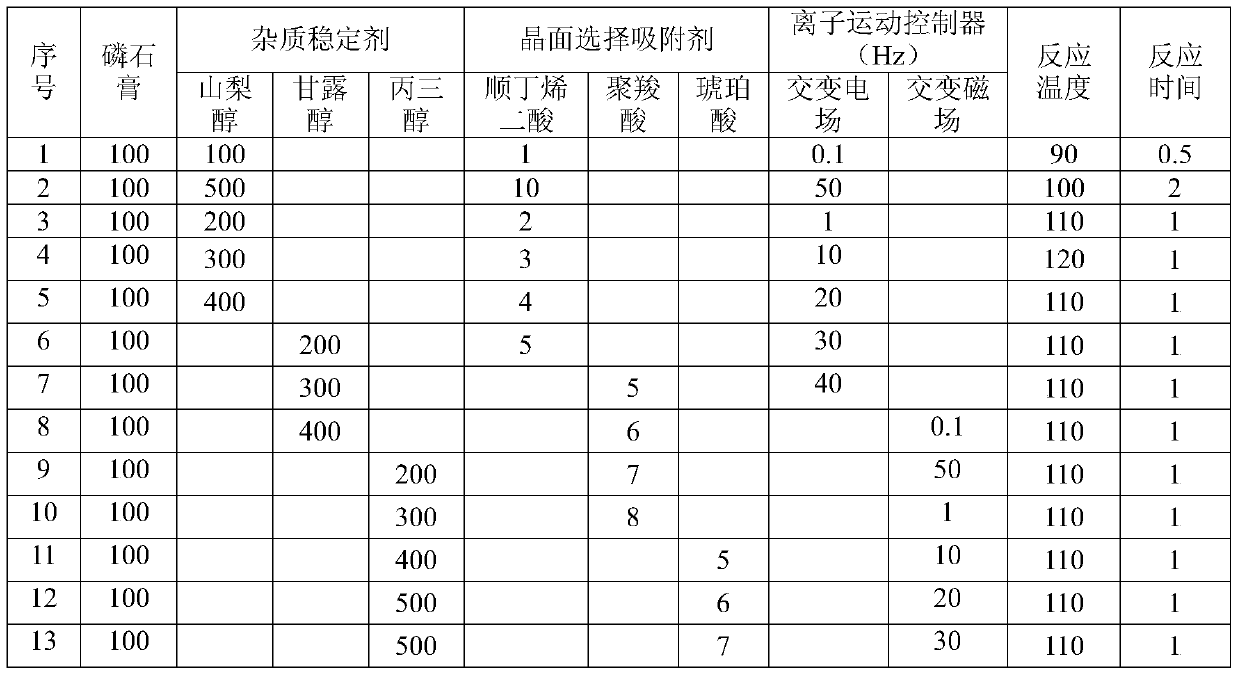

[0020] B: Preparation of gypsum single crystal

[0021] The processed phosphogypsum obtained in step A is poured into a reactor with a reflux device for condensation, an impurity stabilizer, a crystal surface selective adsorbent are added, and the mixture is uniformly mixed, and then a heating reaction is performed. At the same time, an ion motion controller is added to the reaction system. After the reaction, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com