A kind of heat treatment method of n-type silicon chip

A heat treatment method and heat treatment furnace technology are applied in the field of silicon materials, which can solve the problems affecting the conversion efficiency of solar cells and the high impurity content of n-type silicon wafers, and achieve the effects of improving lifespan and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

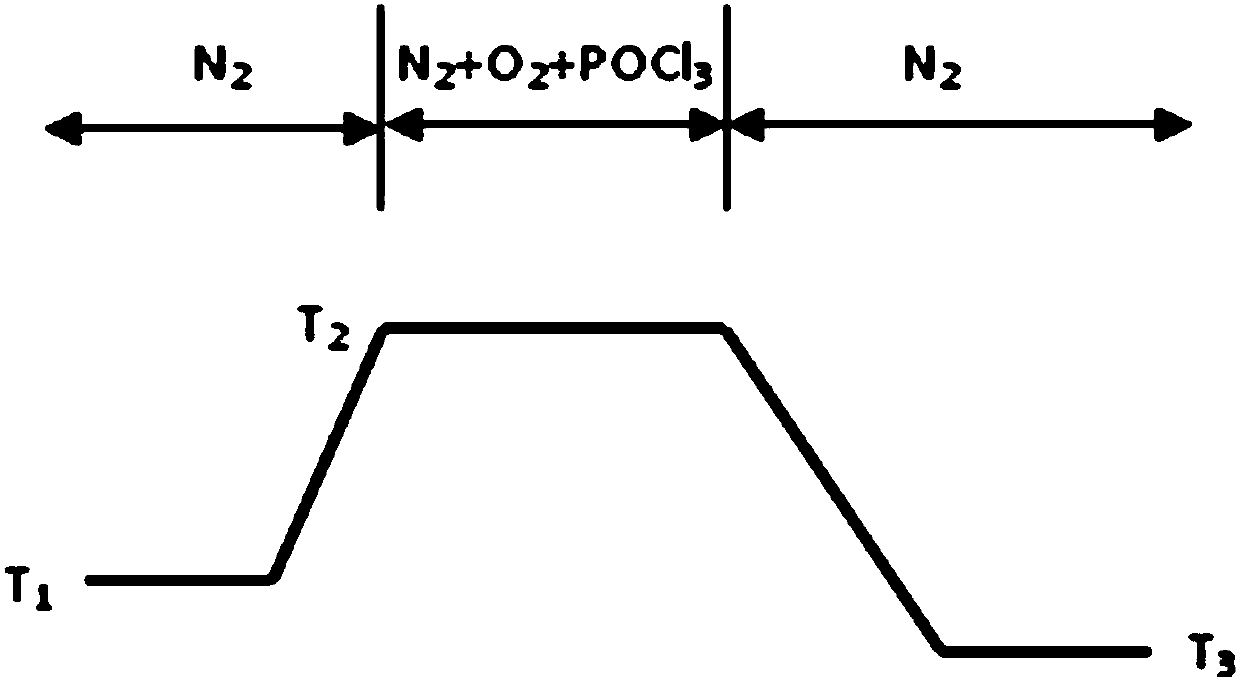

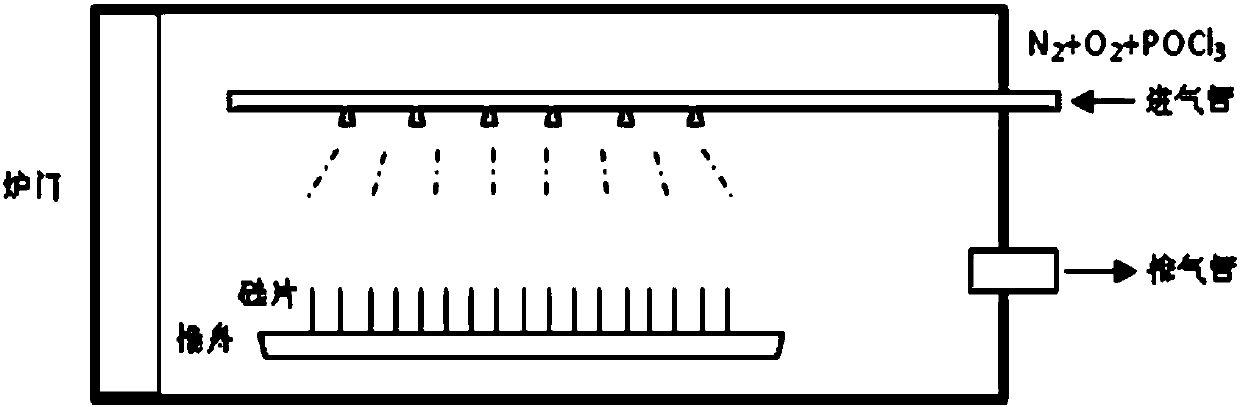

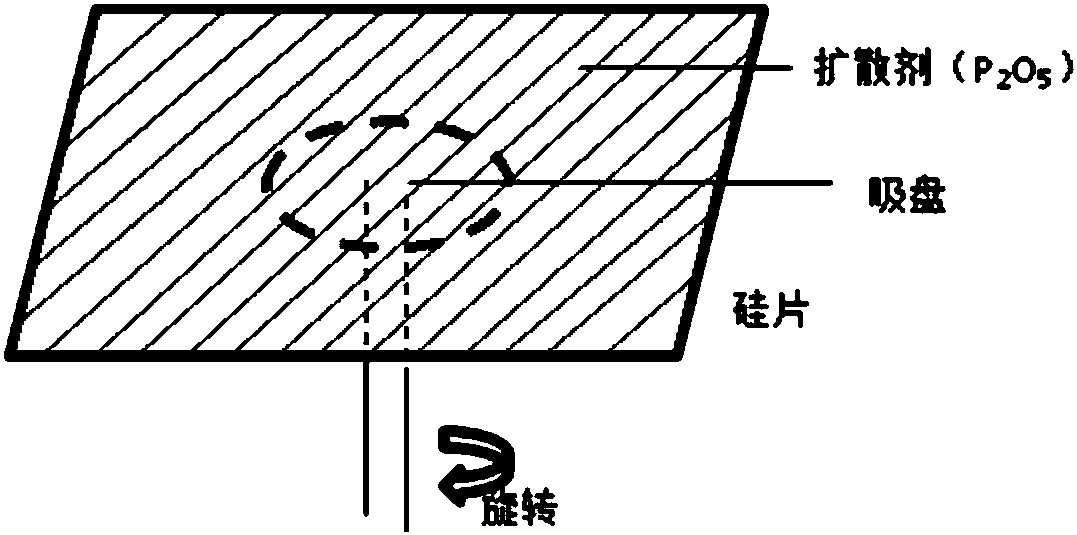

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a specific implementation method for improving the conversion efficiency of an n-type crystalline silicon heterojunction solar cell by using the heat treatment technology of the present invention. The crystalline silicon heterojunction solar cell is also the SHJ solar cell introduced above.

[0043] In this embodiment, an n-type monocrystalline silicon wafer is used. The four side lengths of the silicon wafer are 156.75 mm, and the rounded corner diameter is 205 mm. After slicing, it is cleaned and packaged in clean plastic for solar cells.

[0044] First, a KOH aqueous solution is used to de-damage the silicon wafer. The concentration of the KOH aqueous solution is 20%, the temperature is 85 degrees, and the etching thickness of one side of the silicon wafer in the thickness direction is about 10 microns. After sufficient water washing, the surface is cleaned with an aqueous solution of ammonia water and hydrogen peroxide, and after water wash...

Embodiment 2

[0059] This embodiment provides another technical path for the n-type doped layer. In this embodiment, the manufacturing method and process of using silicon wafers, heat treatment furnaces and solar cells are exactly the same as those in Embodiment 1.

[0060]Use n-type monocrystalline silicon wafers. The four side lengths of the silicon wafers are 156.75mm, and the diameter of the rounded corners is 205mm. After slicing, they are cleaned and packaged in clean plastic for solar cells.

[0061] First, a KOH aqueous solution is used to de-damage the silicon wafer. The concentration of the KOH aqueous solution is 20%, the temperature is 85 degrees, and the etching thickness of one side of the silicon wafer in the thickness direction is about 10 microns. After sufficient water washing, the surface is cleaned with an aqueous solution of ammonia water and hydrogen peroxide, and after water washing again, the silicon oxide layer on the surface is removed with 2% HF aqueous solution....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com