Hot water drawing groove for spinning and manufacturing method and application thereof

A technology of hot water and drafting, which is applied in wet spinning, stretch spinning, textiles and papermaking, etc. It can solve the problems of broken filaments, raw filaments and raw filaments wrapped around rolls, etc., to reduce disturbance, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

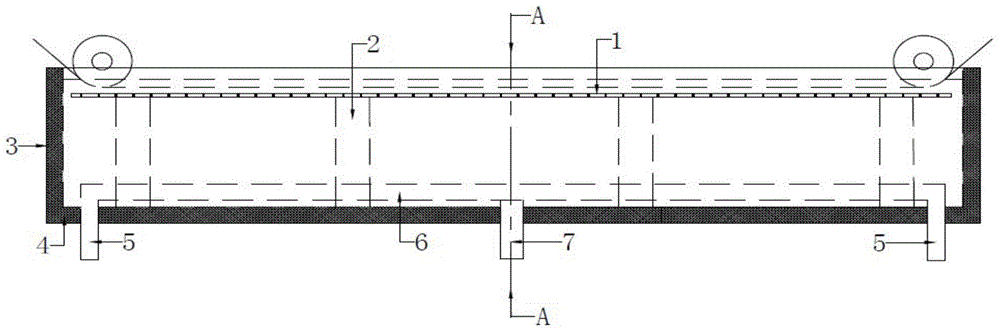

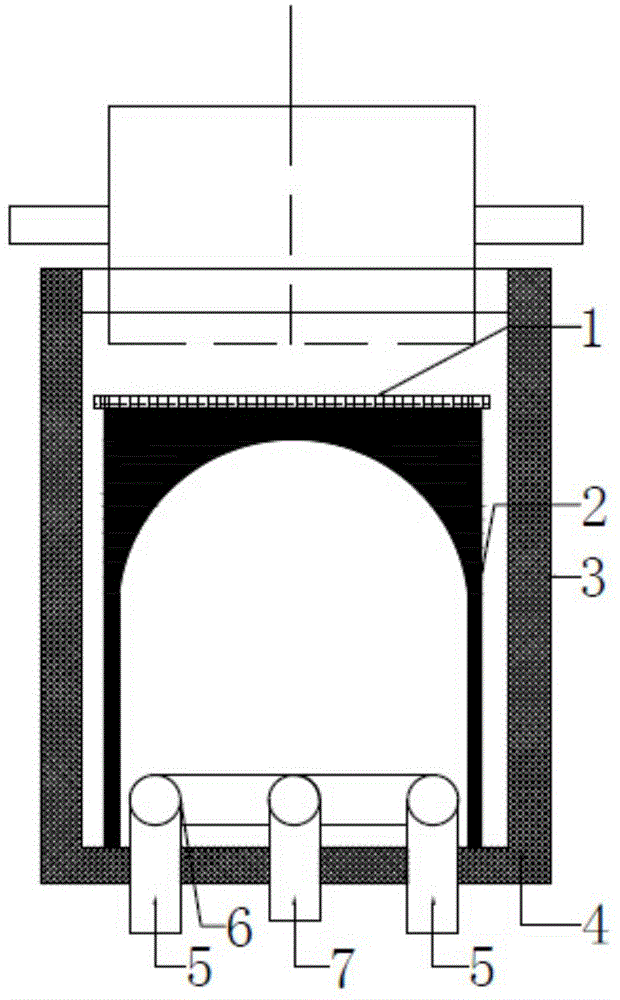

Image

Examples

Embodiment 1

[0038] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 59° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material to obtain an acrylonitrile copolymer spinning solution. After testing, the molecular weight is 80021, the molecular weight distribution is 3.34, and the viscosity is 75 Pa·S at 60°C.

[0039] 2. Coagulation forming: The spinning dope is metered by a metering pump, filtered again at 3 μm, extruded through a spinneret and then enters the first coagulation bath. The temperature of the coagulation bath is 20°C, the concentrat...

Embodiment 2

[0048] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 59° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material to obtain an acrylonitrile copolymer spinning solution. After testing, the molecular weight is 80021, the molecular weight distribution is 3.34, and the viscosity is 75 Pa·S at 60°C.

[0049] 2. Coagulation forming: The spinning dope is metered by a metering pump, filtered again at 2 μm, extruded through a spinneret and then enters the first coagulation bath. The temperature of the coagulation bath is 25°C, the concentrat...

Embodiment 3

[0058] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 59° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material to obtain an acrylonitrile copolymer spinning solution. After testing, the molecular weight is 80021, the molecular weight distribution is 3.34, and the viscosity is 75 Pa·S at 60°C.

[0059] 2. Coagulation forming: The spinning dope is metered by a metering pump, filtered again at 3 μm, extruded through a spinneret and then enters the first coagulation bath. The temperature of the coagulation bath is 48°C, the concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com