Twisting frame and spinning workshop monitoring system

A monitoring system and twisting machine technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems such as the inability to realize comprehensive monitoring of the twisting machine and the spinning workshop at the same time, and the low degree of intelligence. Ensure product quality and production process safety, high degree of intelligence, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

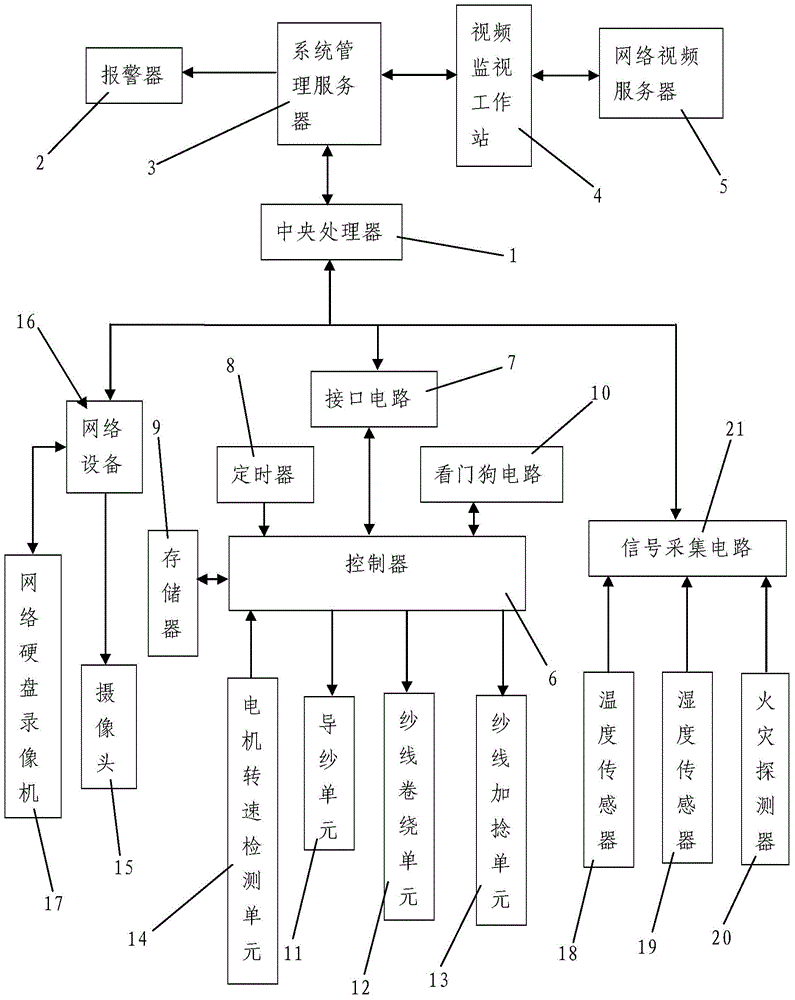

[0023] like figure 1 As shown, the present invention includes a monitoring center, a central processing unit 1, a twister control system, an image acquisition system and an environment acquisition system arranged in the spinning workshop; the monitoring center includes an alarm device 2 and a system management server that are signally connected to each other. 3. Video monitoring workstation 4 and network video server 5; the twisting machine control system includes a controller 6, a communication interface circuit 7, a timer 8, a memory 9, a watchdog circuit 10, a yarn guide unit 11, a yarn roll Winding unit 12, yarn twisting unit 13 and motor speed detection unit 14, the communication interface circuit 7, timer 8, memory 9, watchdog circuit 10, yarn guiding unit 11, yarn winding unit 12, yarn Both the thread twisting unit 13 and the motor speed detection unit 14 are connected to the controller 6; the image acquisition system includes several cameras 15 arranged in the spinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com