High-strength impact-resistant power cable

A power cable and impact-resistant technology, which is applied in the field of high-strength impact-resistant power cables, can solve the problems of threatening life and property safety, poor impact toughness, and short service life, etc., to achieve broad application range, excellent impact resistance, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

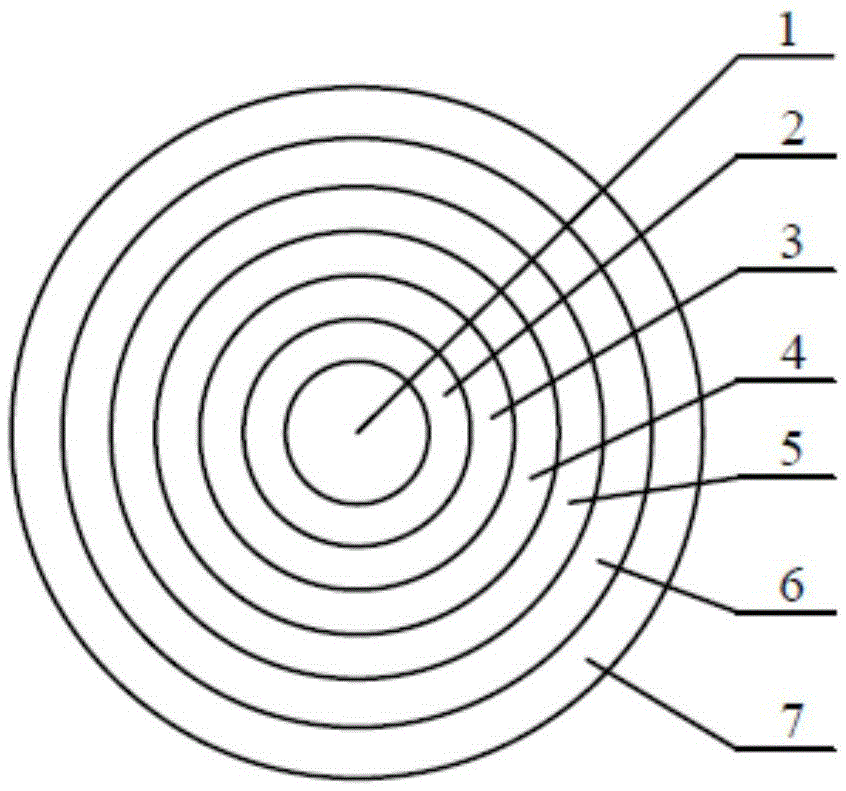

[0018] figure 1 It is a structural schematic diagram of the high-strength impact-resistant power cable of the present invention, referring to figure 1 , a high-strength impact-resistant power cable proposed by the present invention, comprising a conductor 1, a conductor wrapping layer 2 is wrapped around the conductor 1, an insulating layer 3 is wrapped outside the conductor wrapping layer 2, and the The insulating layer 3 is covered with an insulating wrapping layer 4, the insulating wrapping layer 4 is covered with a metal shielding layer 5, and the metal shielding layer 5 is covered with a shielding wrapping layer 6. The shielding wrapping layer 6 is covered with a sheath layer 7; wherein, the sheath layer 7 is prepared from a modified unsaturated polyester composite material; the raw materials of the modified unsaturated polyester composite material are Parts include: 100 parts of unsaturated polyester resin, 15 parts of ethylene-butylene elastomer, 3 parts of styrene, 20...

Embodiment 2

[0020] refer to figure 1 , a high-strength impact-resistant power cable proposed by the present invention, comprising a conductor 1, a conductor wrapping layer 2 is wrapped around the conductor 1, an insulating layer 3 is wrapped outside the conductor wrapping layer 2, and the The insulating layer 3 is covered with an insulating wrapping layer 4, the insulating wrapping layer 4 is covered with a metal shielding layer 5, and the metal shielding layer 5 is covered with a shielding wrapping layer 6. The shielding wrapping layer 6 is covered with a sheath layer 7; wherein, the sheath layer 7 is prepared from a modified unsaturated polyester composite material; the raw materials of the modified unsaturated polyester composite material are Parts include: 100 parts of unsaturated polyester resin, 5 parts of ethylene-butylene elastomer, 15 parts of styrene, 5 parts of polyacrylonitrile fiber, 12 parts of basalt fiber, 5 parts of ammonium polyphosphate, aluminum diethylphosphinate 10 ...

Embodiment 3

[0022] refer to figure 1 , a high-strength impact-resistant power cable proposed by the present invention, comprising a conductor 1, a conductor wrapping layer 2 is wrapped around the conductor 1, an insulating layer 3 is wrapped outside the conductor wrapping layer 2, and the The insulating layer 3 is covered with an insulating wrapping layer 4, the insulating wrapping layer 4 is covered with a metal shielding layer 5, and the metal shielding layer 5 is covered with a shielding wrapping layer 6. The shielding wrapping layer 6 is covered with a sheath layer 7; wherein, the sheath layer 7 is prepared from a modified unsaturated polyester composite material; the raw materials of the modified unsaturated polyester composite material are Parts include: 100 parts of unsaturated polyester resin, 12 parts of ethylene-butylene elastomer, 6 parts of styrene, 14 parts of polyacrylonitrile fiber, 7 parts of basalt fiber, 10 parts of ammonium polyphosphate, aluminum diethylphosphinate 5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com