Composite type pesticide penetrant and preparing method thereof

A penetrant and composite technology, applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve the problems of high production cost, poor water solubility, and difficulty in dilution, and achieve convenient production and operation, improved surface activity, The effect of improving the efficacy of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

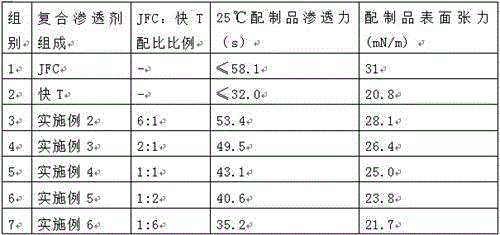

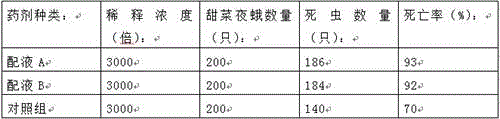

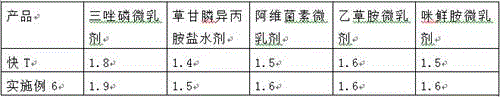

Examples

Embodiment 1

[0024] A composite pesticide penetrating agent, the raw materials of the following quality are taken: 2.9 g of dioctyl sulfosuccinate sodium salt; 17.1 g of fatty alcohol polyoxyethylene ether; and 80 g of water. At a temperature of 20°C, add dioctyl sulfosuccinate sodium salt (Quick T), fatty alcohol polyoxyethylene ether (JFC), and water into a container equipped with a stirrer in sequence, turn on the stirrer and stir for 10 minutes , until fully mixed evenly, the finished product is obtained.

Embodiment 2

[0026] A compound pesticide penetrating agent, the following raw materials are taken: 2.9 g of dioctyl sulfosuccinate sodium salt; 17.1 g of fatty alcohol polyoxyethylene ether; 79.7 g of water; and 0.3 g of preservative. At a temperature of 20°C, add dioctyl sulfosuccinate sodium salt (Quick T), fatty alcohol polyoxyethylene ether (JFC), water, and preservatives into a container equipped with an agitator in sequence, and turn on the agitator Stir for 10 minutes until fully mixed evenly to obtain the finished product.

Embodiment 3

[0028] A composite pesticide penetrating agent, the raw materials of the following quality are taken: 6.7 g of dioctyl sulfosuccinate sodium salt; 13.3 g of fatty alcohol polyoxyethylene ether; 79.7 g of water; and 0.3 g of preservative. At a temperature of 20°C, add dioctyl sulfosuccinate sodium salt (Quick T), fatty alcohol polyoxyethylene ether (JFC), water, and preservatives into a container equipped with an agitator in sequence, and turn on the agitator Stir for 10 minutes until fully mixed evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com