Compound photocatalyst and preparing method and application thereof

A catalyst, composite light technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of poor adsorption performance, fast photogenerated electron hole recombination rate, The visible light catalytic performance is not particularly high, and the effects of excellent adsorption performance, easy operation and low cost are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

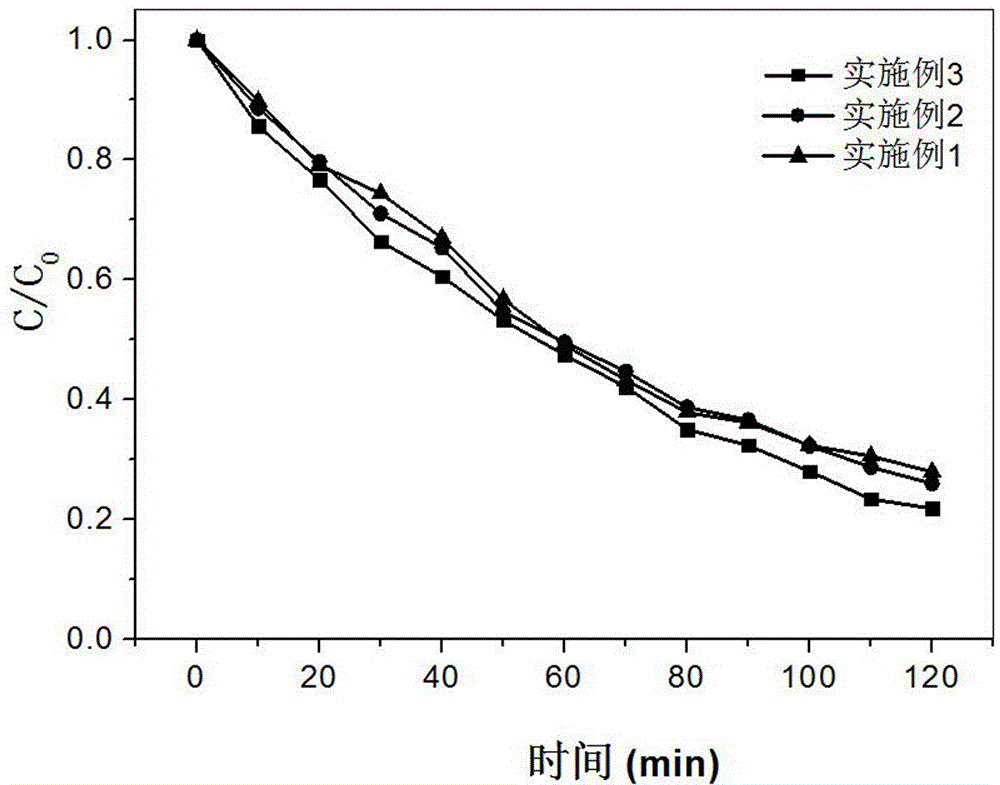

Embodiment 1

[0027] (1) Prepare 75mL of 95mg / LZnCl 2 Solution, add 15mg sodium dodecylbenzene sulfonate at the same time, put 2g kapok into the solution and soak for 2 hours, take it out and dry it at 80°C, then calcinate it at 900°C under nitrogen, and heat up during the calcining process The rate is 5°C / min, the holding time is 1h, then the temperature is lowered to 300°C, and finally cooled naturally to room temperature to obtain ACFs;

[0028] (2) Take 20mg of ACFs described in step (1), mix with 0.242g sodium molybdate and 0.38g thiourea, dissolve in 60mL distilled water, stir evenly, transfer the prepared reaction solution into the lining of 100mL hydrothermal reaction kettle Put it into a hydrothermal reactor for reaction, the reaction temperature is 210°C, and the holding time is 24h. After the reaction is completed, cool to room temperature, remove the supernatant, filter, wash, and dry to obtain MoS 2 / ACFs;

[0029] (3) Take 200mg of MoS as described in step (2) 2 / ACFs is pl...

Embodiment 2

[0031] (1) Prepare 85mL of 95mg / LZnCl 2 Solution, add 15mg sodium dodecylbenzene sulfonate at the same time, put 2g kapok into the solution and soak for 2 hours, take it out and dry it at 80°C, then calcinate it at 900°C under nitrogen, and heat up during the calcining process The rate is 5°C / min, the holding time is 1h, then the temperature is lowered to 300°C, and finally cooled naturally to room temperature to obtain ACF;

[0032] (2) Take 20mg of ACF described in step (1), mix with 0.242g sodium molybdate and 0.38g thiourea, dissolve in 60mL distilled water, stir evenly, transfer the prepared reaction solution into the lining of 100mL hydrothermal reaction kettle Put it into a hydrothermal reactor for reaction, the reaction temperature is 210°C, and the holding time is 24h. After the reaction is completed, cool to room temperature, remove the supernatant, filter, wash, and dry to obtain MoS 2 / ACFs;

[0033] (3) Take 200mg of MoS as described in step (2) 2 / ACFs is plac...

Embodiment 3

[0035] (1) Configure 80mL of 95mg / LZnCl 2 Solution, add 15mg sodium dodecylbenzene sulfonate at the same time, put 2g kapok into the solution and soak for 2 hours, take it out and dry it at 80°C, then calcinate it at 900°C under nitrogen, and heat up during the calcining process The rate is 5°C / min, the holding time is 1h, then the temperature is lowered to 300°C, and finally cooled naturally to room temperature to obtain ACFs;

[0036] (2) Take 20mg of ACFs described in step (1), mix with 0.242g sodium molybdate and 0.38g thiourea, dissolve in 60mL distilled water, stir evenly, transfer the prepared reaction solution into the lining of 100mL hydrothermal reaction kettle Put it into a hydrothermal reactor for reaction, the reaction temperature is 210°C, and the holding time is 24h. After the reaction is completed, cool to room temperature, remove the supernatant, filter, wash, and dry to obtain MoS 2 / ACFs;

[0037] (3) Take 200mg of MoS as described in step (2) 2 / ACFs is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com