Polypropylene material for baby carriage main beam and preparing method thereof

A polypropylene material and polypropylene technology, applied in the field of polymer materials, can solve the problems of reducing the rigidity of polypropylene materials, difficulty in meeting requirements, and high prices, and achieve the effects of improving scratch resistance, low production costs, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

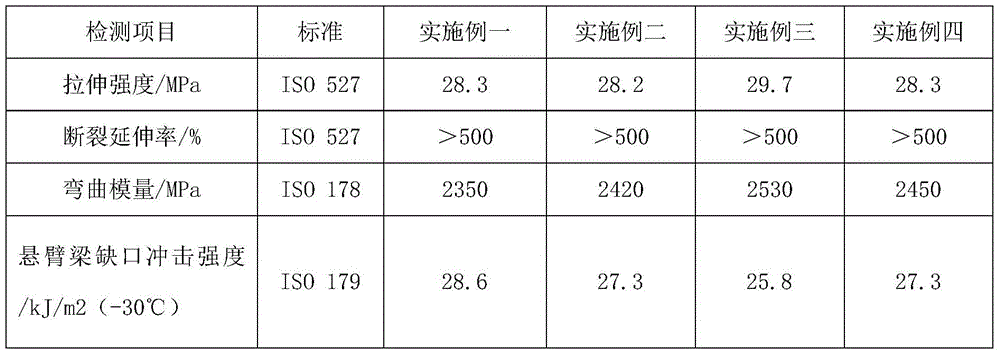

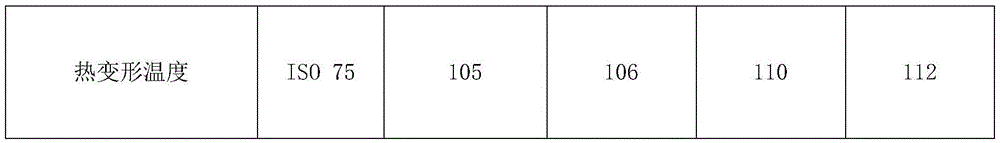

Embodiment 1

[0035] 40 parts of copolymerized polypropylene with a melt index of 5g / 10min, 15 parts of high-melt-strength polypropylene with a dispersion coefficient of 4 and a melt strength of 18cN, and 30 parts of high-crystalline copolymerized polypropylene with a crystallinity of 70%. 10100.8 parts of antioxidants, 1681.2 parts of antioxidants, 38080.5 parts of light stabilizers, and 1 part of calcium stearate were put into a high-speed mixer and mixed for 4 minutes to obtain a mixture of the above components; the obtained mixture was added to the main feed hopper In the twin-screw extruder, intermeshing and mixing; at the same time, 11.5 parts of 5000 mesh talc powder is added to the barrel of the twin-screw extruder through the side feed port, after extrusion, drawing, air drying, and granulation Through other procedures, the polypropylene material for the structure of the baby carriage is obtained; among them, the barrel temperature of the twin-screw extruder is zone I: 160°C, zone II...

Embodiment 2

[0037] 44.4 parts of copolymer polypropylene with a melt index of 10g / 10min, 5 parts of high melt strength polypropylene with a dispersion coefficient of 5 and a melt strength of 26cN, and 20 parts of high crystal copolymer polypropylene with a crystallinity of 75%. 10100.08 parts of antioxidants, 1680.12 parts of antioxidants, 38080.1 parts of light stabilizers, and 0.3 parts of polyethylene wax were placed in a high-speed mixer and mixed for 6 minutes to obtain the above-mentioned mixture of components; the obtained mixture was added to the double through the main feed hopper In the screw extruder, intermeshing and mixing; at the same time, 30 parts of talc powder with a particle size of 10,000 mesh is added to the barrel of the twin screw extruder through the side feeding port, and then extruded, stretched, air-dried, granulated, etc. The program obtains the polypropylene material for the structure of the baby carriage; among them, the barrel temperature of the twin screw ext...

Embodiment 3

[0039] 60 parts of copolymer polypropylene with a melt index of 20g / 10min, 8.2 parts of high melt strength polypropylene with a dispersion coefficient of 4 and a melt strength of 20cN, and 20 parts of high crystal copolymer polypropylene with a crystallinity of 73%. 10100.4 parts of antioxidant, 1680.6 parts of antioxidant, 7700.3 parts of light stabilizer, and 0.5 part of stearic acid amide were put into a high-speed mixer and mixed for 4 minutes to obtain a mixture of the above components; the obtained mixture was added to the main feed hopper In the twin-screw extruder, intermeshing and kneading are carried out; at the same time, 10 parts of whiskers with a length-to-diameter ratio of 150:1 are added to the barrel of the twin-screw extruder through the side feeding port, and then extruded, stretched, and air-dried , Granulation and other procedures to obtain the polypropylene material for the structure of the baby carriage; among them, the barrel temperature of the twin-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com