Heavy tar and fine powder treatment method

A heavy tar and treatment method technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, cracking, etc., can solve the problems that restrict the clean and efficient utilization of coal, and the difficulty of effective utilization of fine powder and heavy tar, so as to improve the carbon conversion rate and the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

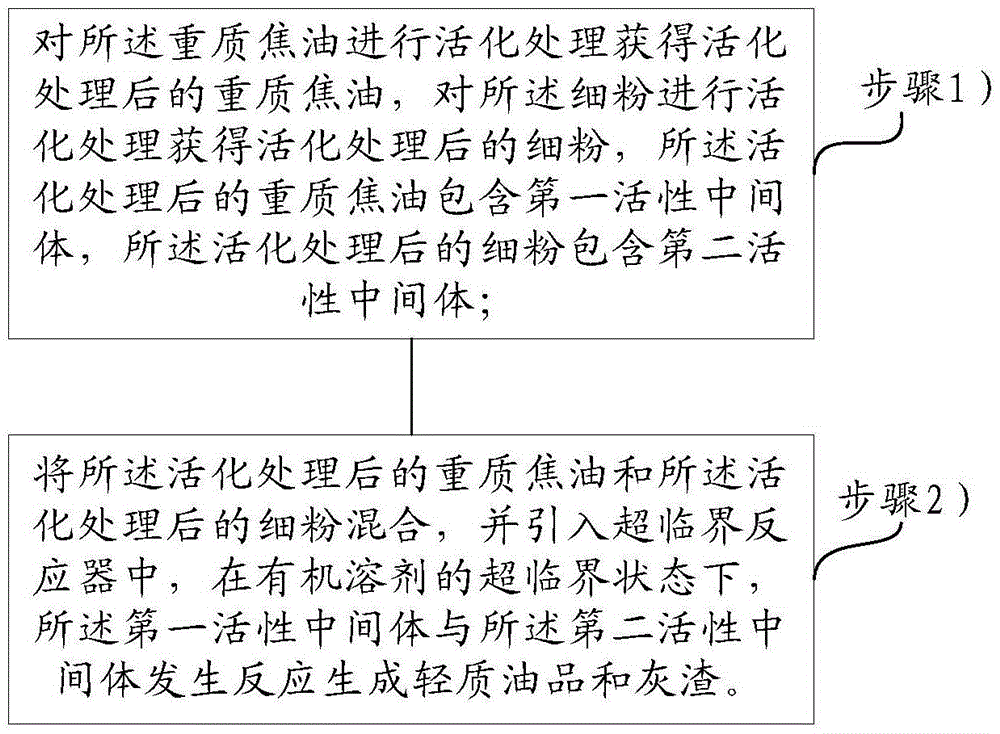

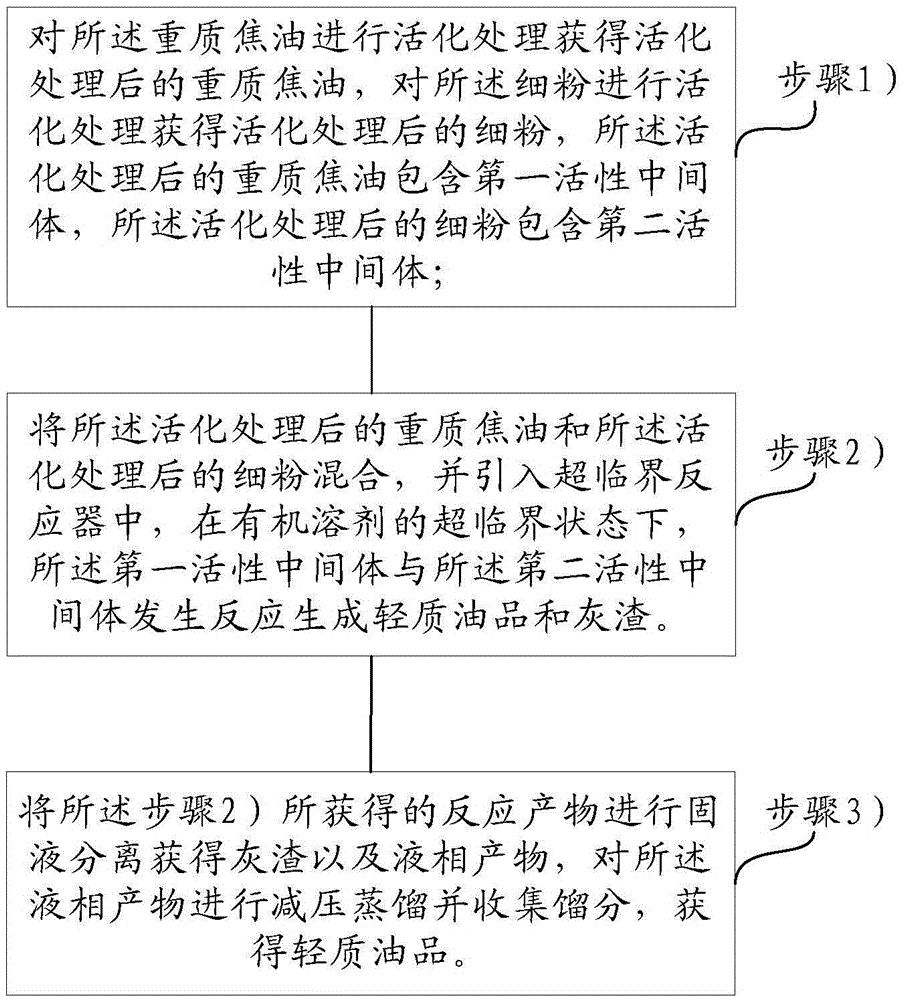

Method used

Image

Examples

Embodiment 1

[0085] Use 1# coal as the raw material for catalytic gasification, collect heavy tar and fine powder in the product, and detect the temperature and proportion of each fraction of heavy tar, as shown in Table 1:

[0086] Table 1

[0087] Distillation temperature / ℃

[0088] 1. Carry out pretreatment to described heavy tar and described fine powder respectively

[0089] The heavy tar and (toluene and methanol) mixed solution were mixed at a mass ratio of 4:1, ultrasonically oscillated for 1.5h, and the fine powder was activated with steam at 180°C for 1.2h, and the steam and the The mass ratio of the fine powder is 3.

[0090] 2. Mix the mixture of the heavy tar after the activation treatment with the mixed solution and the fine powder after the activation treatment, the mass ratio of the fine powder to the heavy tar is 2.5, and stir for 2.5 hours at a speed of 250 rpm .

[0091]3. React for 1.5 hours at a temperature of 380° C. and a pressure of 22 MPa in a supercri...

Embodiment 2

[0097] Use 2# coal as the raw material for catalytic gasification, collect heavy tar and fine powder in the product, and detect the temperature and proportion of each fraction of heavy tar, as shown in Table 3:

[0098] table 3

[0099] Distillation temperature / ℃

[0100] 1. Carry out pretreatment to described heavy tar and described fine powder respectively

[0101] The heavy tar and toluene were mixed at a mass ratio of 7:1, ultrasonically oscillated for 1 h, and the fine powder was activated with steam at 220° C. for 2 h, and the mass ratio of the steam to the fine powder was 2.2.

[0102] 2. Under the protection of nitrogen, mix the heavy tar after the activation treatment with the mixture of the mixed solution and the fine powder after the activation treatment, the mass ratio of the fine powder to the heavy tar is 4, at 350 rpm Stirring at high speed for 1.5h.

[0103] 3. React for 2 hours in a supercritical state with a temperature of 350°C and a pressure of ...

Embodiment 3

[0109] Use 3# coal as the raw material for catalytic gasification, collect heavy tar and fine powder in the product, and detect the temperature and proportion of each fraction of heavy tar, as shown in Table 5:

[0110] table 5

[0111] Distillation temperature / ℃

<180

180-210

210-230

230-300

300-360

>360

Mass percentage / %

0.9

1.13

5.67

4.55

24.3

63.45

[0112] 1. Carry out pretreatment to described heavy tar and described fine powder respectively

[0113] The heavy tar and (toluene, methanol and tetrahydrofuran) mixed solution were mixed at a mass ratio of 5.5:1, ultrasonically oscillated for 2 hours, and the fine powder was activated with steam at 250°C for 3 hours, and the steam and the The mass ratio of the fine powder is 3.5.

[0114] 2. Under the protection of nitrogen, mix the heavy tar after the activation treatment with the mixture of the mixed solution and the fine powder after the activation tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com