Rapid liquid submerged fermentation method for producing paecilomyces cicadae powder

A technology of deep liquid fermentation and Paecilomyces cicadae, applied in the field of microorganisms, can solve the problems of large workload of sewage treatment system, decreased product quality and yield, large consumption of manpower and material resources, etc., so as to improve the utilization rate of equipment and clarify the filtrate. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

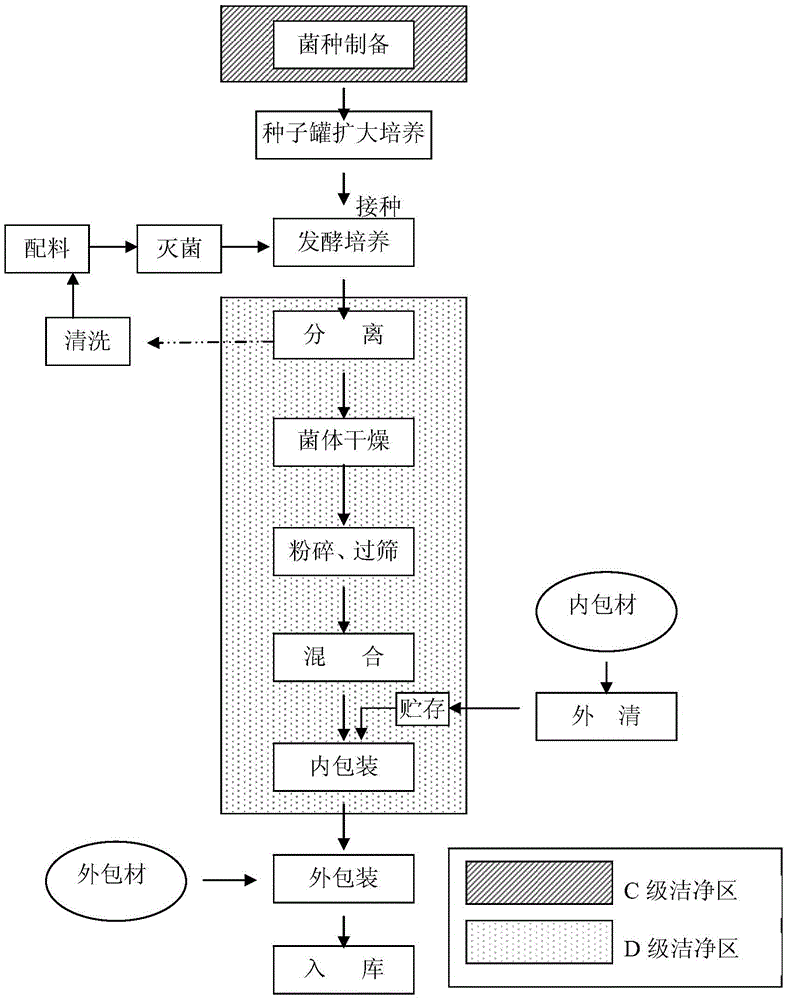

Method used

Image

Examples

Embodiment 1

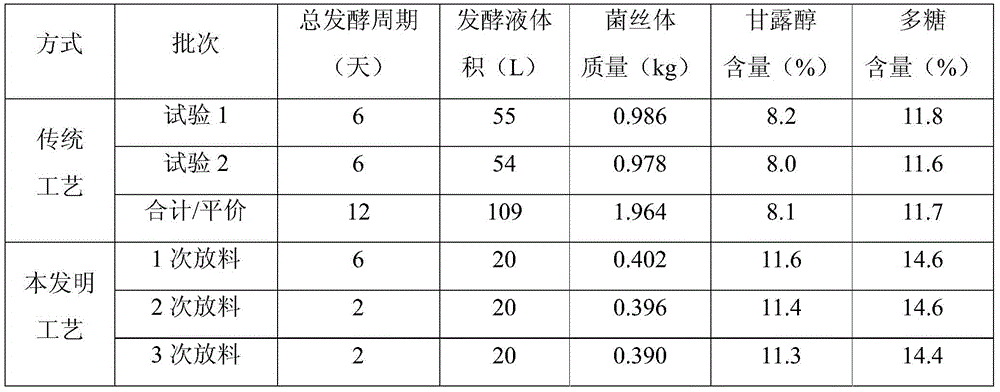

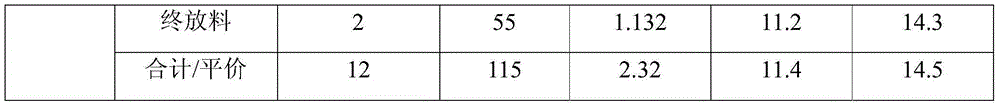

[0029] 1) Paecilomycescicadae (Paecilomycescicadae), preserved in the Microorganism Resource Center of Yunnan University, with the preservation number YUMCCc359. The cultivated Paecilomyces cicadae strain seed solution is seeded into the seed medium, the inoculum size is 10%, and the seed medium consists of 2% glucose, 1% bran, 1.5% peptone, 0.5% yeast powder, 0.2% serine, Potassium dihydrogen phosphate 0.3%, magnesium sulfate heptahydrate 0.2%, soybean oil 0.02%; adjust the pH value to 5.5. The cultivation conditions are: the ventilation ratio is 1:0.5vvm, the tank pressure is 0.03Mpa, the cultivation temperature is 26-28°C, and the seed liquid can be obtained after culturing for about 5 days. Inoculate the cultivated seed liquid into 50L fermentation medium after sterilization, the inoculum size is 15% by volume percentage, and the fermentation medium composition (weight percentage) is glucose 2%, bran 1%, peptone 1.5%, yeast Powder 0.5%, serine 0.2%, potassium dihydrogen p...

Embodiment 2

[0037] 1) Paecilomycescicadae (Paecilomycescicadae), preserved in the Microorganism Resource Center of Yunnan University, with the preservation number YUMCCc359. Seed the cultured Paecilomyces cicadae strain seed liquid into the seed medium, the seed medium consists of 1.8% glucose, 0.8% bran, 1.5% peptone, 0.4% yeast powder, 0.2% serine, and 0.3% potassium dihydrogen phosphate , magnesium sulfate heptahydrate 0.2%, soybean oil 0.02%; adjust the pH value to 5.5. The cultivation conditions are: the ventilation ratio is 1:0.5vvm, the tank pressure is 0.03Mpa, the cultivation temperature is 26-28°C, and the seed liquid can be obtained after culturing for about 5 days. Inoculate the cultivated seed liquid into 50L fermentation medium after sterilization, the inoculation amount is 15%, and the fermentation medium is composed of 1.8% glucose, 1.2% bran, 1.5% peptone, 0.6% yeast powder, 0.2% serine, dihydrogen phosphate Potassium 0.3%, magnesium sulfate heptahydrate 0.2%, soybean oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com