Feeding silk antibacterial peptide preparation and preparation method thereof

An antibacterial peptide and silk technology, which is applied in the field of animal feed additives, can solve problems such as the gap of effect and effect, and achieve the effects of mild environment, good development prospects and reduction of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

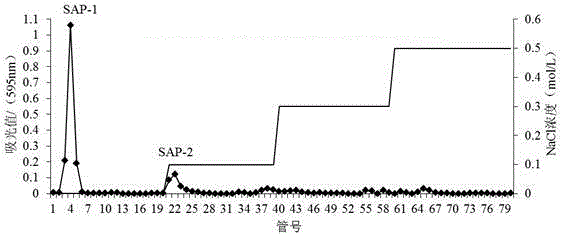

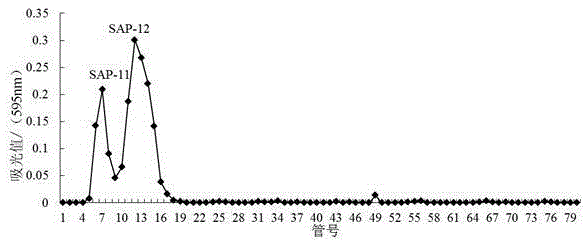

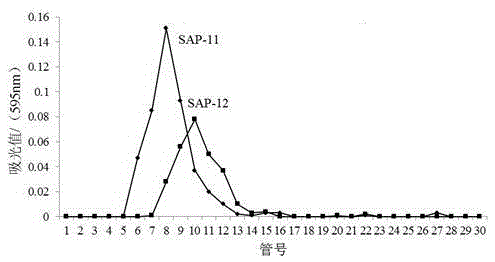

Image

Examples

Embodiment Construction

[0033] The above-mentioned content of the present invention is further described through the implementation form below. A feed silk antimicrobial peptide preparation and a preparation method thereof include the following steps:

[0034] (1) Analytical balance Weigh 1000g of waste silk, add 300mL of 0.5% sodium carbonate solution, extract for 40min, and obtain degummed silk, and use undegummed silk as a control test.

[0035] (2) Put the undegummed and degummed silk fibroin samples obtained in step (1) into an oven, bake them at a temperature of (65±1)°C to constant weight, and put them in a desiccator for cooling. After stabilizing at room temperature for 12 hours, weigh them with an electronic balance to obtain the dry weights of degummed silk and non-degummed silk, expressed in M 1 and M 2 Indicates that the degumming rate is calculated.

[0036] (3) The degummed silk obtained in step (2) is dissolved in 40% calcium chloride solution, and the degummed silk is concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com