Method for preparing lead telluride alloy thermoelectric material through melt spinning and inductive hot-pressing

A technology of thermoelectric materials and lead telluride, applied in the field of thermoelectric materials, can solve the problems of inapplicability to large-scale process production and application, complex preparation process, and lower thermal conductivity, etc., to achieve the suppression of nanoparticle growth, simple preparation process, Effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

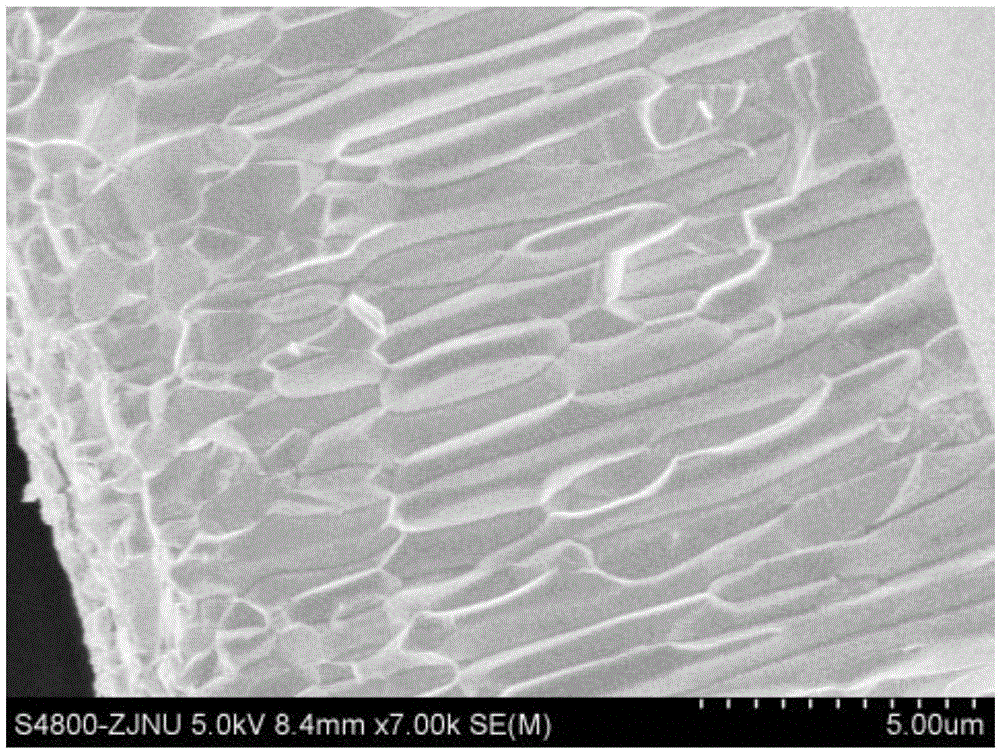

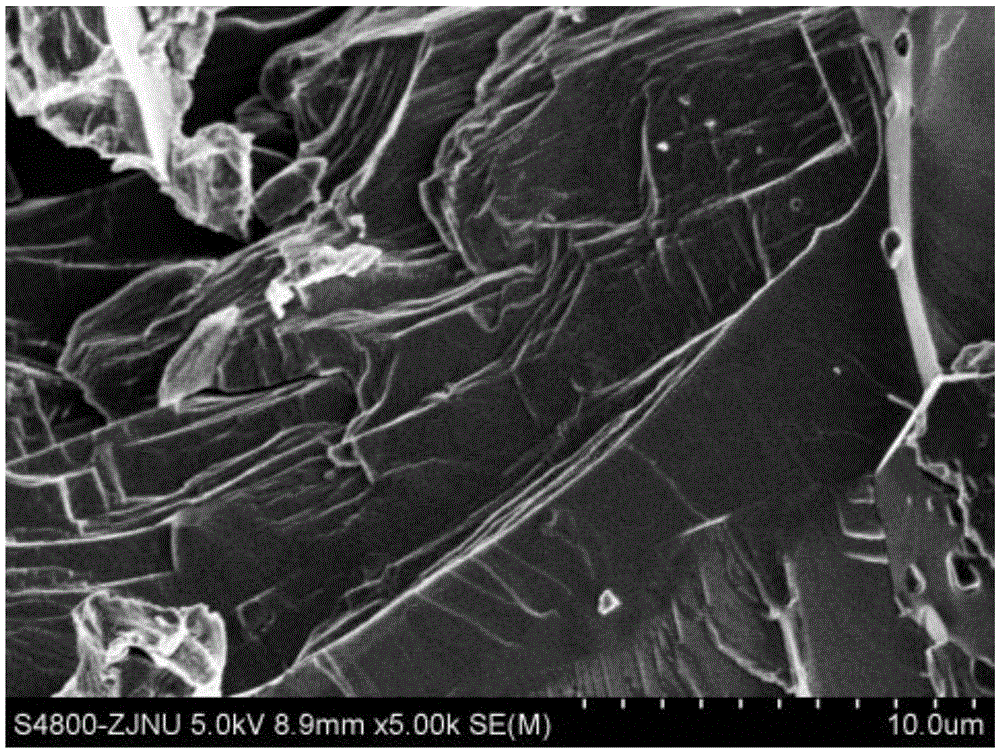

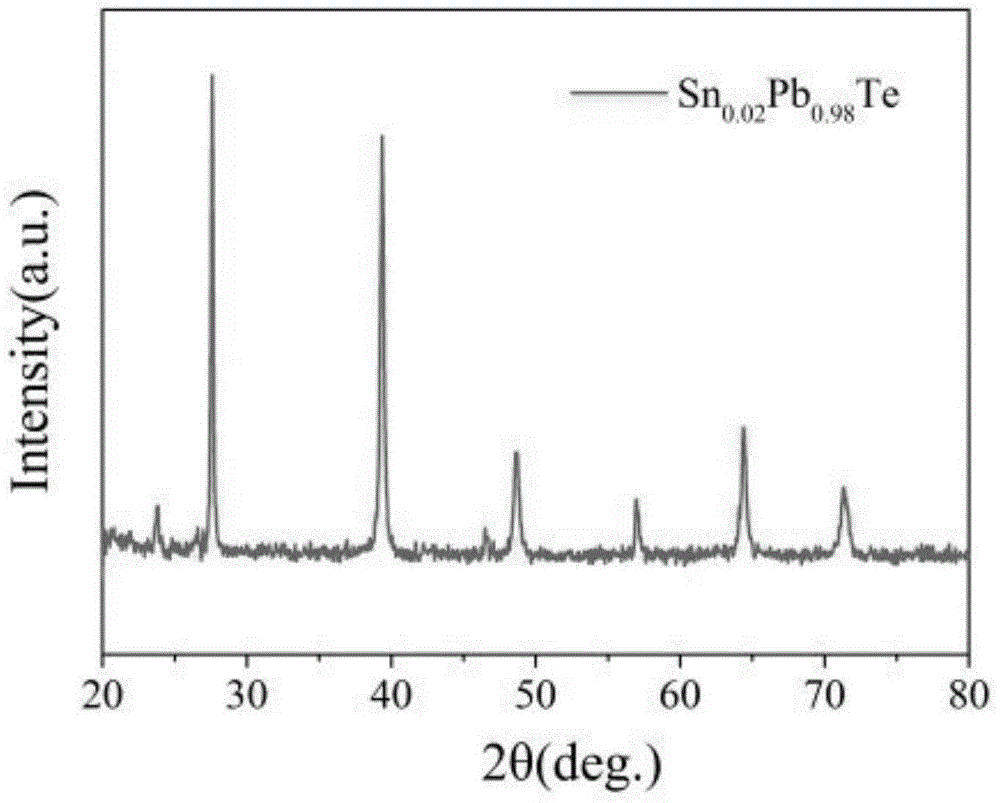

[0051] A method for preparing a lead telluride alloy thermoelectric material in combination with melt spinning and spinning, comprising the following steps:

[0052] A. Ingredients

[0053] According to the chemical formula Pb 0.98 sn 0.02 Weigh Te, take powdered Pb, Te and Sn, the mass purity of Pb and Te is ≥99.999%, the mass purity of metal elemental Sn is ≥99.95%, and mix uniformly to obtain the raw material composition;

[0054] B. Preparation of master alloy

[0055] Put the raw material composition into a high-temperature container, and then put the high-temperature container into an induction melting furnace. The high-temperature container is preferably a quartz glass tube, and the induction melting furnace is first vacuumed to 5×10 -2 Pa, then fill in an inert gas with a mass purity ≥ 99.99% to 0.01MPa for protection, repeat vacuuming and filling inert gas, cycle more than 3 times, and then carry out under the condition that the induction coil voltage is 220V and t...

Embodiment 2

[0062] A method for preparing a lead telluride alloy thermoelectric material in combination with melt spinning and spinning, comprising the following steps:

[0063] A. Ingredients

[0064] According to the chemical formula Pb 0.91 Ti 0.09 Weigh Te, take powdered Pb, Te and Ti, the mass purity of Pb and Te is ≥99.999%, the mass purity of metal elemental Ti is ≥99.95%, and mix uniformly to obtain the raw material composition;

[0065] B. Preparation of master alloy

[0066] Put the raw material composition into a high-temperature container, and then put the high-temperature container into an induction melting furnace. The high-temperature container is preferably a quartz glass tube, and the induction melting furnace is first vacuumed to 5×10 -2 Pa, then fill in an inert gas with a mass purity ≥ 99.99% to 0.01MPa for protection, repeat vacuuming and filling inert gas, cycle more than 3 times, and then carry out under the condition that the induction coil voltage is 220V and t...

Embodiment 3

[0073] A method for preparing a lead telluride alloy thermoelectric material in combination with melt spinning and spinning, comprising the following steps:

[0074] A. Ingredients

[0075] According to the chemical formula Pb 0.96 Cd 0.04 Weighing Te, weighing powdered Pb, Te and Cd, the mass purity of Pb and Te is ≥99.999%, the mass purity of metal element Cd is ≥99.95%, and mixing uniformly to obtain the raw material composition;

[0076] B. Preparation of master alloy

[0077] First put the raw material composition into a high-temperature container, and then put the high-temperature container into an induction melting furnace. The high-temperature container is preferably a quartz glass tube, and the induction melting furnace is first evacuated to 5×10 -2 Pa, then fill in an inert gas with a mass purity ≥ 99.99% to 0.01MPa for protection, repeat vacuuming and filling inert gas, cycle more than 3 times, and then carry out under the conditions of the induction coil voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com