Mold-proof, antibacterial and anti-corrosion cable used for power transmission

A cable and antibacterial technology, applied in power cables, insulated cables, cables, etc., can solve the problems of destroying intermolecular regularity, reducing the tensile strength of aramid fibers, and damage to aramid fibers. The effect of investment and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The preparation of embodiment 1 polypeptide and thin film

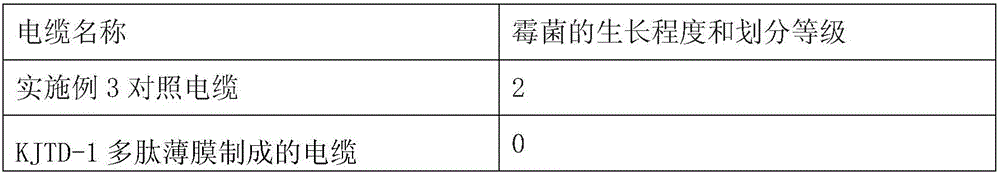

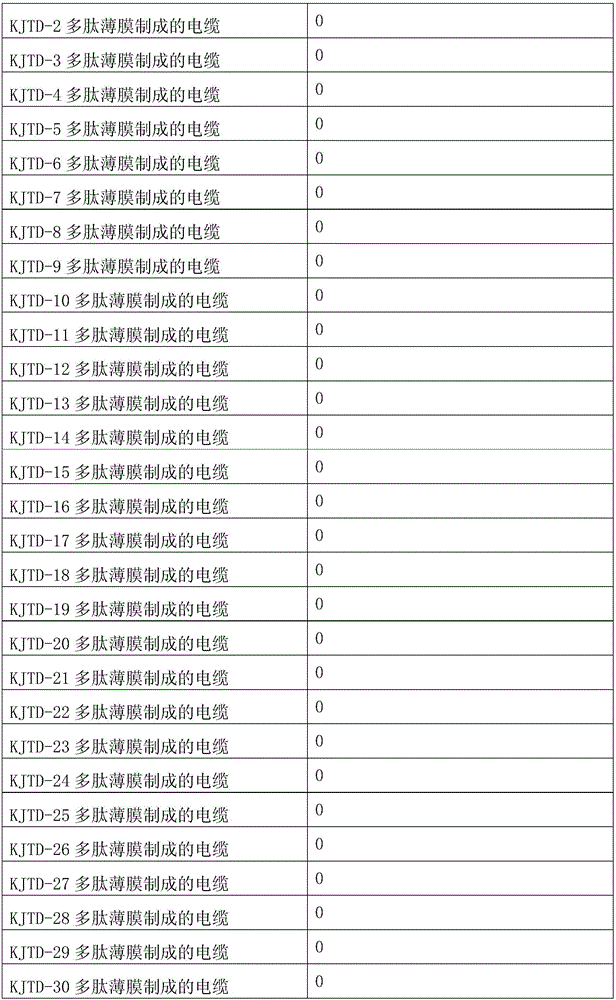

[0014] Firstly, the peptide database was constructed, and then the computer simulation screening technology was used for high-throughput screening of antimicrobial peptides. From the results of computer screening, 116 polypeptides capable of specifically inhibiting mold functions were selected, and through conventional verification tests, it was confirmed that these polypeptides had the function of inhibiting mold growth and killing corresponding molds. The polypeptides are respectively named as KJTD-1-116, and their sequences correspond to SEQ ID NO: 1-116 respectively. The polypeptide is artificially synthesized for subsequent batch industrial production.

[0015] The polypeptide is prepared into a thin film layer, the method is as follows: (1) raw material mixing: at 25°C, heat 3g of 4,4'-diaminodiphenyl ether and 54mL of N,N-dimethylacetamide in a three-necked flask, After ultrasonic stirring until comple...

Embodiment 2

[0017] Preparation of Embodiment 2 Cable

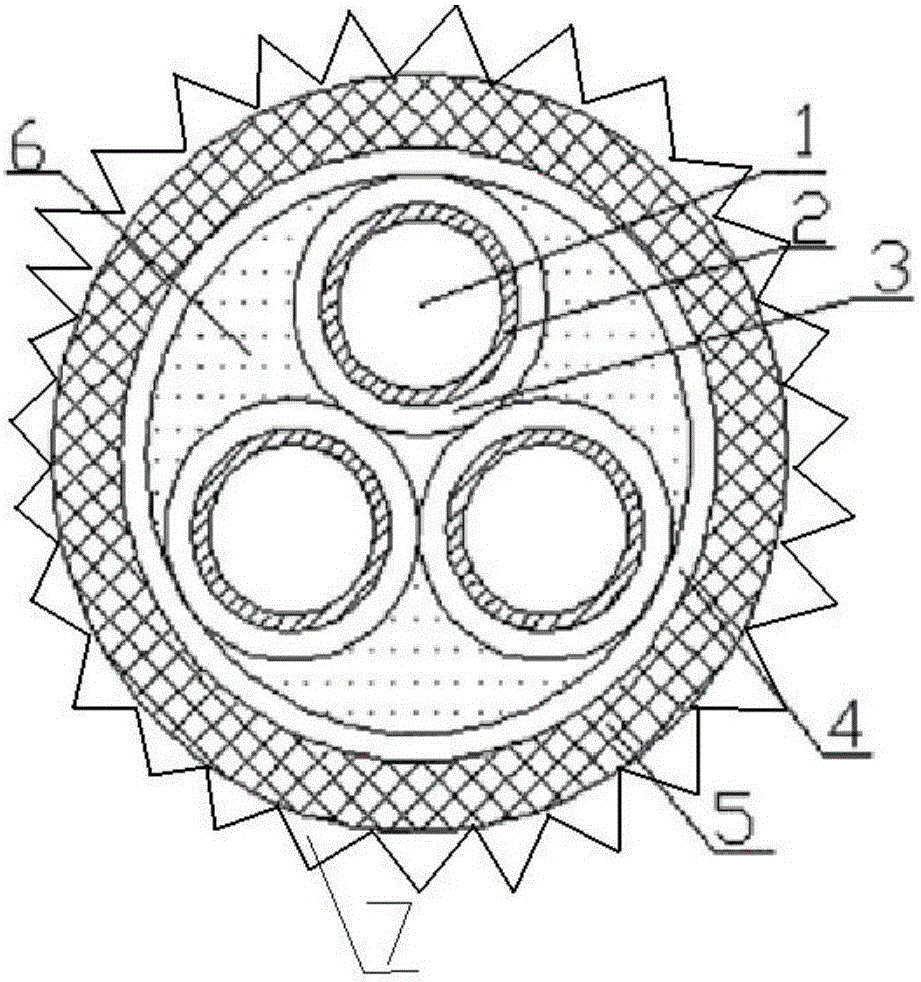

[0018] According to the conventional cable preparation method in this field, according to figure 1 The method of preparation is to prepare the cable, wherein when the film is prepared as the outermost layer of the cable, it can rely on polyethylene to prepare a zigzag film layer, so that the cable has a larger contact sterilization specific surface area, Can better sterilize. The cables are based on different polypeptide film layers, and a total of 116 types have been prepared.

Embodiment 3

[0019] The preparation of embodiment 3 contrast cables

[0020] According to the conventional cable preparation method in this field, according to figure 1 According to the preparation method, the cable is prepared, wherein the film layer is prepared according to the method in Example 1, wherein no polypeptide is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com