Ultraviolet avalanche photo-detector

A photodetector and ultraviolet avalanche technology, applied in the field of photoelectric detection, can solve the problems of high breakdown voltage and high cost, and achieve the effects of low breakdown voltage, low breakdown voltage and noise, and low voltage bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

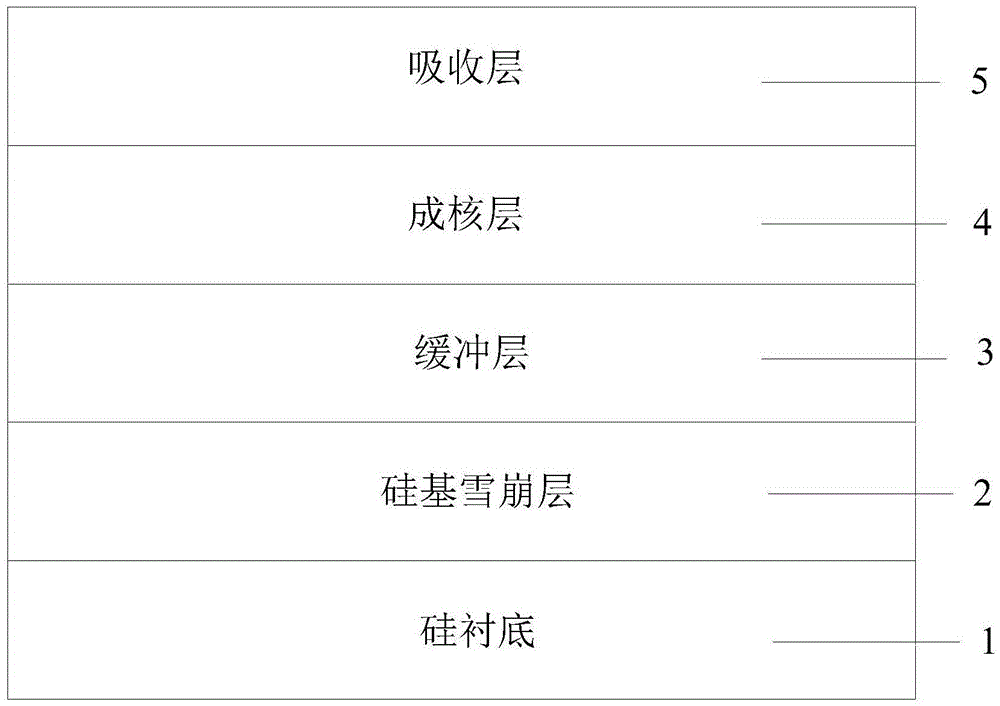

Method used

Image

Examples

Embodiment 1

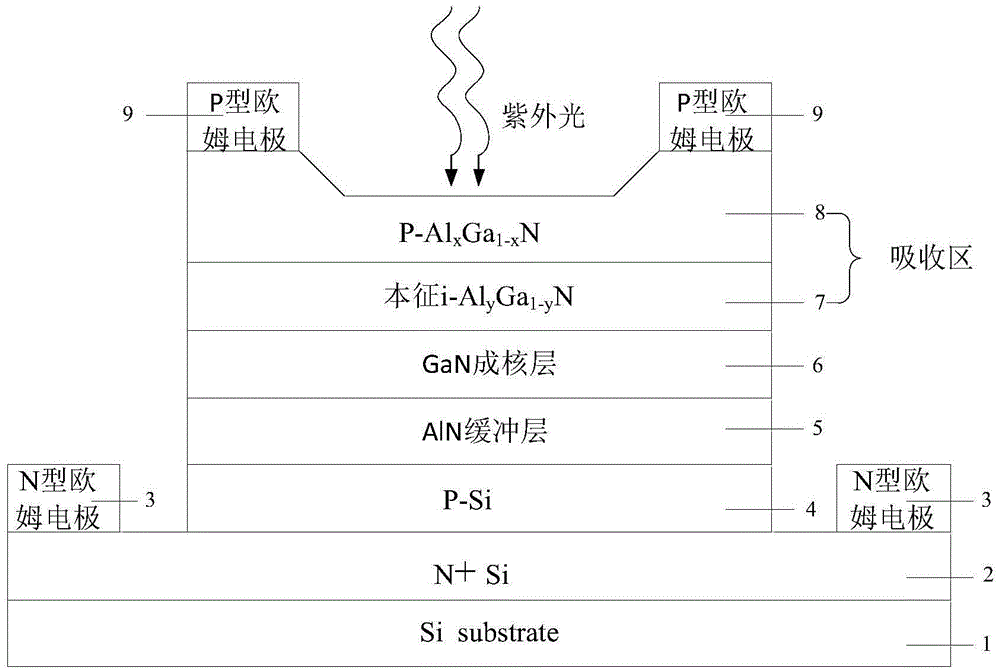

[0019] Such as figure 2 Shown is an ultraviolet avalanche photodetector, which includes from bottom to top: silicon substrate 1, N+ doped silicon 2, P type doped silicon 4, AlN buffer layer 5, GaN nucleation layer 6, intrinsic i- al y Ga 1-y N7, P-type doped P-Al x Ga 1-x N8, P-type ohmic electrode 9 and N-type ohmic electrode 3, wherein intrinsic i-Al y Ga 1-yN 7 and P-type doped P-Al x Ga 1-x N8 acts as an absorbing layer to absorb ultraviolet light, and P-type doped silicon 4 and N+ doped silicon 2 form a PN junction as a silicon-based avalanche region through photogenerated carriers (mainly electrons) to generate avalanche multiplication, thereby realizing the AlGaN absorption region and the separation of silicon-based multiplication regions.

[0020] In the device structure, from the silicon substrate 1 up, the thickness of the N+ doped silicon 2 is about 1 μm, and the concentration is at least 1×10 19 cm -3 , belonging to the high-concentration end of the PN j...

Embodiment 2

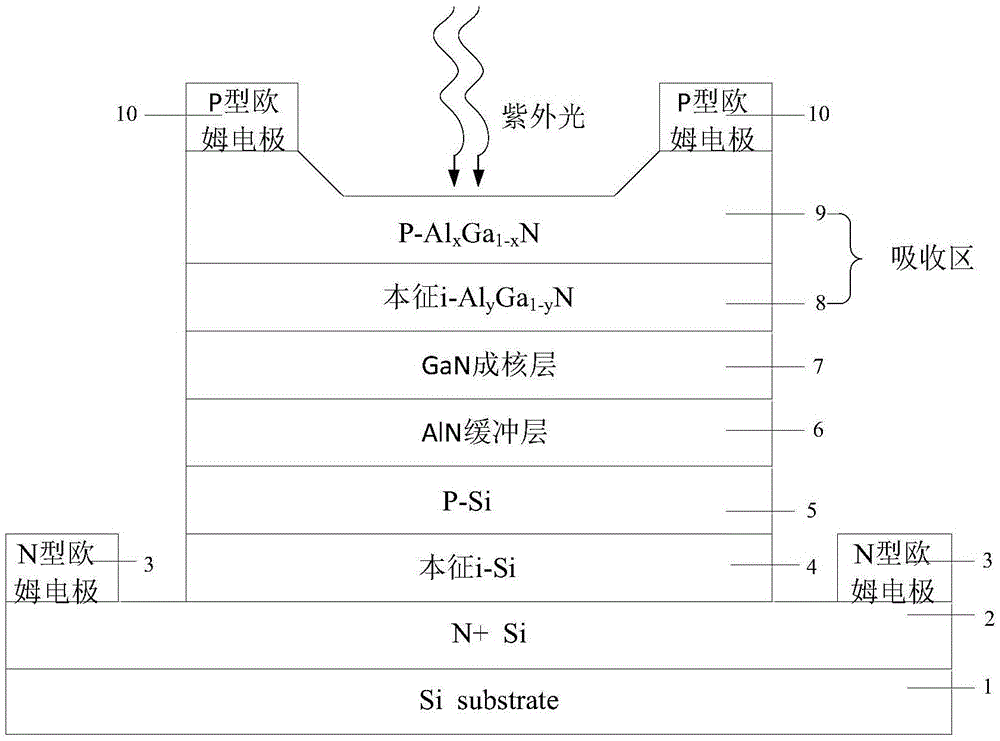

[0027] Such as image 3 Shown is an ultraviolet avalanche photodetector, which includes from bottom to top: silicon substrate 1, N+ doped silicon 2, intrinsic i-Si4, P-type doped silicon P-Si5, AlN buffer layer 6, GaN formed Core layer 7, intrinsic i-Al y Ga 1-y N8, P-type doped P-Al x Ga 1-x N9, P-type ohmic electrode 10 and N-type ohmic electrode 3, wherein intrinsic i-Al y Ga 1-y N8 and P-type doped P-Al x Ga 1-x N9 acts as an absorbing layer to absorb ultraviolet light. P-type doped silicon P-Si5, intrinsic i-Si4 and N+ doped silicon 2 form a PIN structure, which is used as a silicon-based avalanche region to generate photogenerated carriers (mainly electrons). Avalanche multiplication, thereby achieving the separation of the AlGaN absorption region and the silicon-based multiplication region.

[0028] In the device structure, from the silicon substrate 1 up, the thickness of the N+ doped silicon 2 is about 1 μm, and the concentration is at least 1×10 19 cm -3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com