Super-stretchable graphene electro-thermal film and preparation method thereof

A graphene film and graphene technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of complex processing technology, high thermal response temperature, and high cost, and achieve wide availability of raw materials, simple preparation technology, and high cost. Size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of super stretchable highly conductive graphene fiber of the present invention and preparation method thereof, the steps are as follows:

[0022] (1) Graphene oxide is obtained by the natural graphite chemical oxidation exfoliation method, configured into a graphene oxide aqueous solution, and a graphene oxide film with a thickness of 0.5-50 μm is prepared;

[0023] (2) Heat up to 500-800°C at a rate of 0.1-1°C / min, hold for 0.5-2h, then heat up to 1000-1300°C at a rate of 1-3°C / min, hold for 0.5-3h, and then heat for 5- Heat up to 2000-3000°C at a rate of 8°C / min, and hold for 0.5-4h;

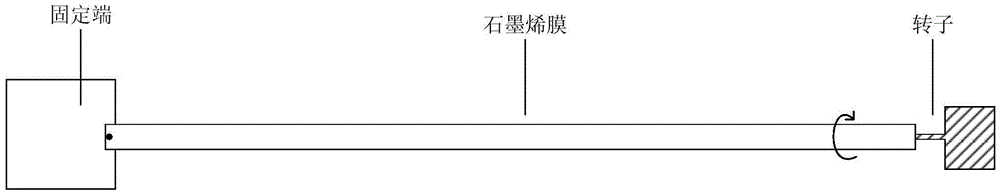

[0024] (3) The graphene film after the heat treatment in step 3 is cut into graphene strips, one end of the graphene strips is fixed, and the other end is connected to a rotor with a rotating speed of 250-300 rpm (one end is fixed, and the other end is continuously driven by the rotor) Turn, similar to rubbing hemp rope, such as figure 1 shown), after winding in the radial dire...

Embodiment 1

[0030] Embodiment 1: the preparation method of a kind of super stretchable highly conductive graphene fiber of the present invention, the steps are as follows:

[0031] (1) Graphene oxide is obtained by natural graphite chemical oxidation exfoliation method, and a graphene oxide film with a thickness of 0.8-50 μm is prepared;

[0032] (2) Heat-treat the graphene oxide film with a thickness of 0.8-50 μm prepared in step 1 according to the methods shown in Table 1-Table 3 to obtain a graphene film.

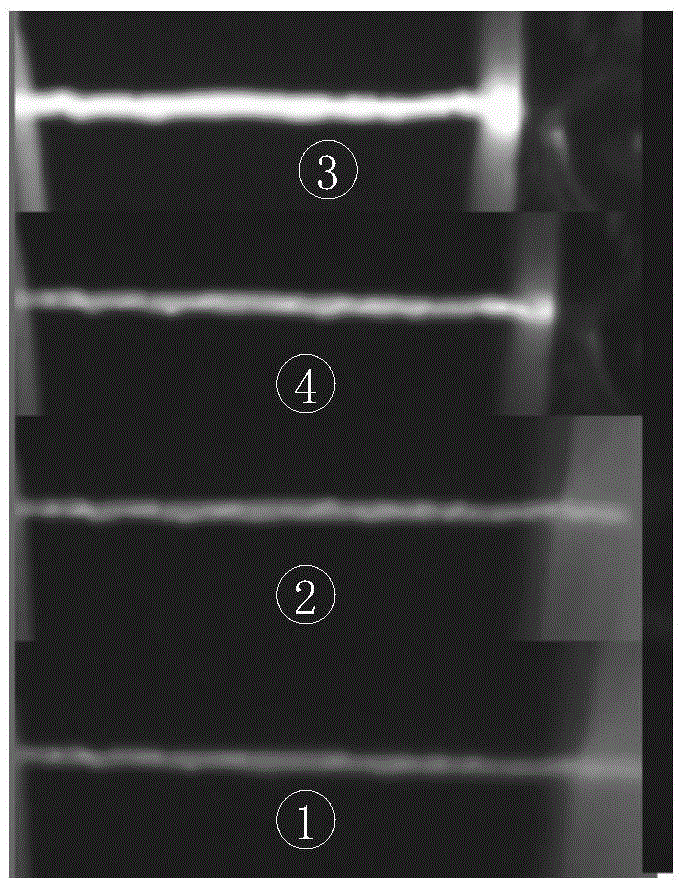

[0033] (3) The graphene film processed in step 2 is cut into graphene strips, one end of the graphene strip is fixed, the other end is connected to a rotor with a rotating speed of 260 rpm, and after radial winding for 3min (one end is fixed, the other is fixed) One end is constantly rotating under the drive of the rotor, similar to rubbing hemp rope, such as figure 2 Shown), the electrical properties of each product obtained by different heat treatment methods are shown in Tables...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com