Focused ion beam-electron beam fused controllable micro-nano machining method

A focused ion beam, micro-nano processing technology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problem that it is difficult to control the precision and quality of FIB-SEM dual-beam synchronous processing, and it is difficult to control the dual-beam synchronous processing process. , affecting the quality of ion beam processing, etc., to achieve high-precision FIB-SEM dual-beam synchronous controllable processing, neutralization of local charge accumulation effects, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

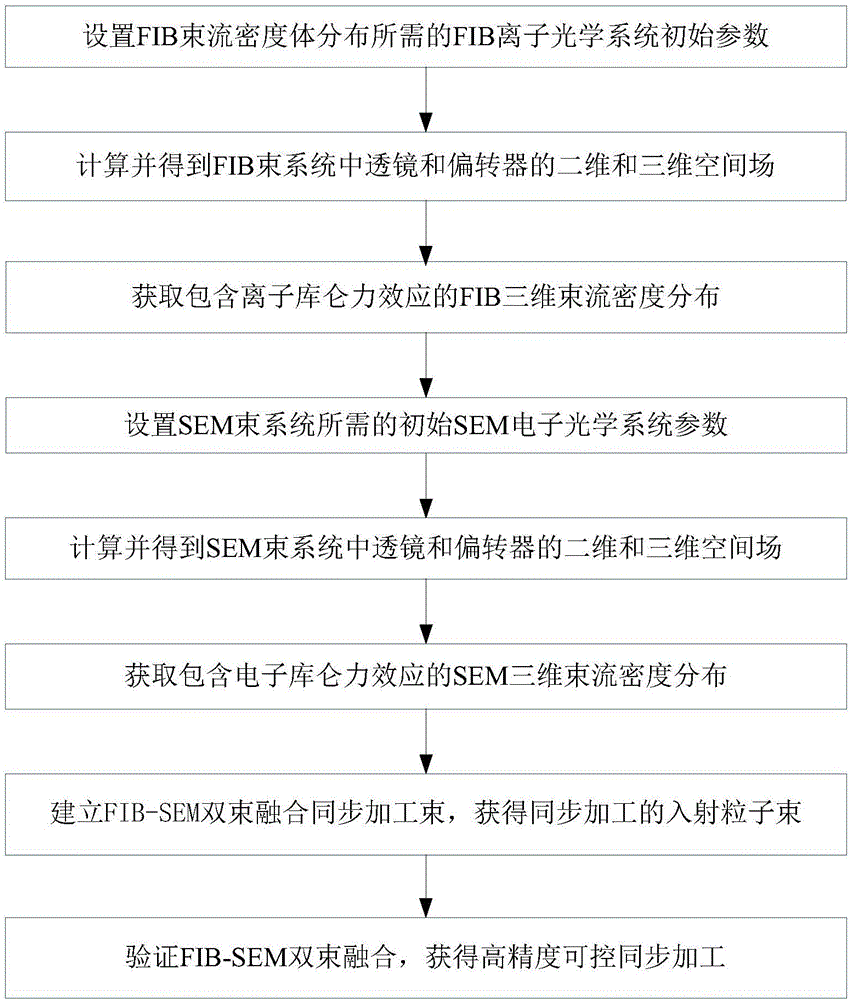

[0064] Since the incident processing beam spot in the FIB-SEM dual-beam synchronous system is small, on the order of nanometers, it is difficult to directly measure the parameters of the incident processing beam, such as velocity, beam density distribution, and incident angle, and is affected by the ion beam and Due to the double impact of electron beams, the types of incident beam particles involve atoms, ions and electrons. It is difficult to control the simultaneous processing of particle beams in existing methods. Therefore, a method of focused ion beam-electron beam dual-beam synchronous and controllable processing is proposed. See figure 1 , the specific operation steps are as follows:

[0065] First, according to the measured results of the dual-beam synchronization system independently integrated in the laboratory, the FIB ion optical system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com