Dyeing wastewater treatment and recycling technical system

A technical system, printing and dyeing wastewater technology, applied in the technical system field of printing and dyeing wastewater treatment and reuse, can solve the problems of human health and living environment hazards, waste of water resources, high chroma, etc., to achieve easy sedimentation of sludge and reduce load , the effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

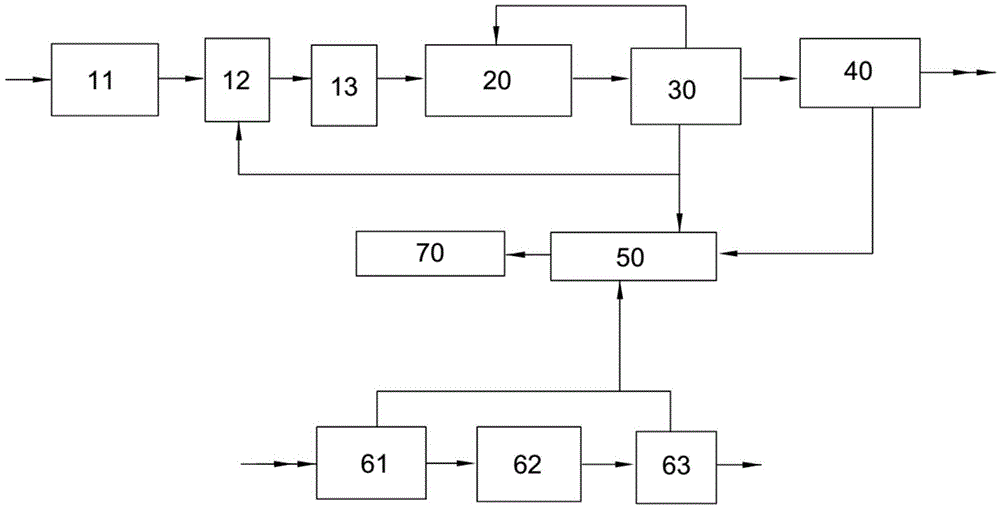

[0041] Such as figure 1 , a technical system for the treatment and reuse of printing and dyeing wastewater, including a pretreatment system, an oxidation ditch, and an advanced treatment system.

[0042] The pretreatment system includes a water collection well 11, a primary sedimentation tank 12, and an adjustment tank 13; the water collection well is connected with the primary sedimentation tank, the primary sedimentation tank is connected with the adjustment tank, the adjustment tank is connected with the oxidation ditch 20, and the oxidation ditch is connected with the secondary sedimentation tank. The pond 30 is connected, and the secondary sedimentation tank is connected with the primary sedimentation tank and the coagulation reaction sedimentation tank 40 respectively; the coagulation reaction sedimentation tank is connected with the sludge thickening tank 50; The bottom of the medicine box is provided with a first medicine dropping port, and ferrous sulfate solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com