Method for two-pot two stage countercurrent dynamic extraction of gardenia yellow pigment

A gardenia yellow pigment, countercurrent technology, applied in the direction of chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid esters, etc., can solve the problem of easy fading and greening of gardenia yellow pigment and the problem of gardenia oil It is easy to extract and clean, and the yellow pigment of gardenia is turbid, so as to reduce the loss of leachate, shorten the leaching time, and not easy to fade and turn green

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

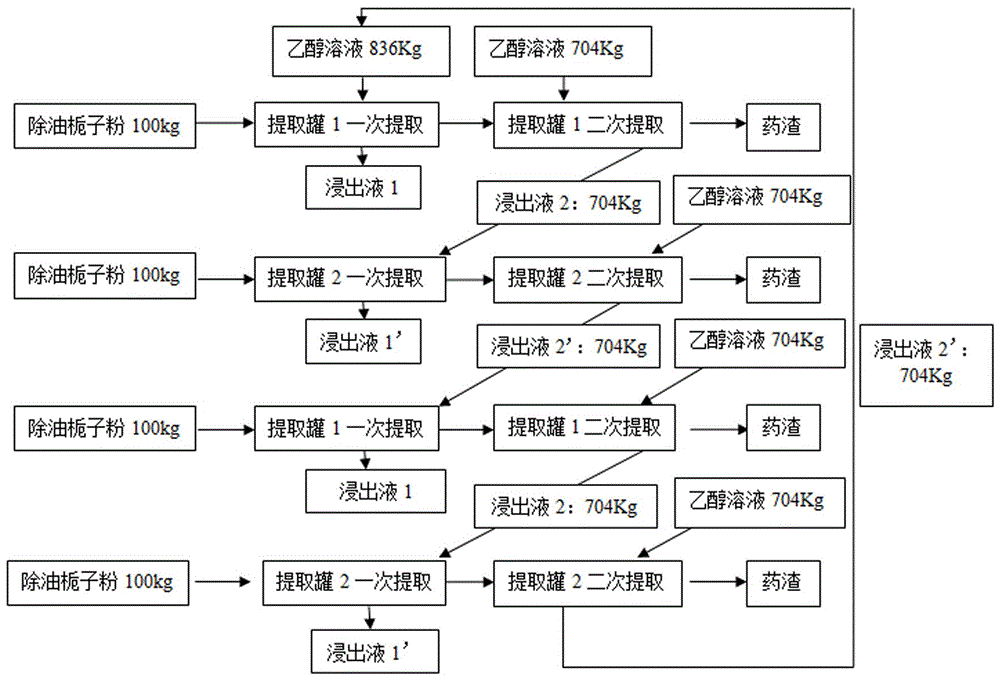

[0029] Such as figure 1 Shown, a kind of double-tank secondary countercurrent dynamic extraction method of gardenia yellow pigment comprises the following steps:

[0030] a. Grinding the shelled gardenia fruit to obtain a powder with a size of 80 meshes, using petroleum ether at 90-120°C as the extraction solvent, the ratio of solid to liquid is 1:6g / ml, and under the condition of 85°C, the petroleum ether is refluxed double Two-stage countercurrent dynamic leaching of tanks, each extraction time of each extraction tank is 1 hour, to obtain gardenia oil petroleum ether leaching solution and medicinal residue; the leaching solution is concentrated at 70-90°C to recover petroleum ether and obtain high-purity gardenia oil , adding an appropriate amount of petroleum ether with a boiling range of 60 to 90°C to the dregs to elute the gardenia oil to obtain degreasing gardenia powder;

[0031]B. with the 55% ethanol solution (55~65% ethanol solution specific gravity of 100kg degreas...

Embodiment 2

[0035] A method for dynamically extracting gardenia yellow pigment in double-tank secondary countercurrent, comprising the following steps:

[0036] a. Grinding the shelled gardenia fruit to obtain a powder with a size of 80 meshes, using petroleum ether at 90-120°C as the extraction solvent, the ratio of solid to liquid is 1:6g / ml, and under the condition of 85°C, the petroleum ether is refluxed double Two-stage countercurrent dynamic leaching of tanks, each extraction time of each extraction tank is 1 hour, to obtain gardenia oil petroleum ether leaching solution and medicinal residue; the leaching solution is concentrated at 70-90°C to recover petroleum ether and obtain high-purity gardenia oil , adding appropriate amount of petroleum ether at 60-90°C to the medicinal dregs to elute gardenia oil to obtain degreasing gardenia powder;

[0037] b. Add 100kg of oil-removed gardenia powder and 1012kg of 60% ethanol solution to extraction tank 1, the ratio of solid to liquid is 1...

Embodiment 3

[0041] A method for dynamically extracting gardenia yellow pigment with two-stage countercurrent in double tanks, is characterized in that it comprises the following steps:

[0042] a. Crush the shelled gardenia fruit to obtain a powder with a size of 80 meshes. Use petroleum ether at 90-120°C as the extraction solvent, and the ratio of solid to liquid is 1:6g / ml. Two-stage countercurrent dynamic leaching of tanks, each extraction time of each extraction tank is 1 hour, to obtain gardenia oil petroleum ether leaching solution and medicinal residue; the leaching solution is concentrated at 70-90°C to recover petroleum ether and obtain high-purity gardenia oil, medicinal dregs, adding appropriate amount of petroleum ether at 60-90°C to elute gardenia oil to obtain degreasing gardenia powder;

[0043] b. Add 100kg degreased gardenia powder and 1188kg65% ethanol solution into extraction tank 1, the ratio of solid to liquid is 1:12g / ml, the pH value is 6.0~8.0, the extraction tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com