Coating adhesive for thermal copy paper and preparation method thereof

A technology for copying paper and adhesives, applied in the direction of non-polymer organic compound adhesives, adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

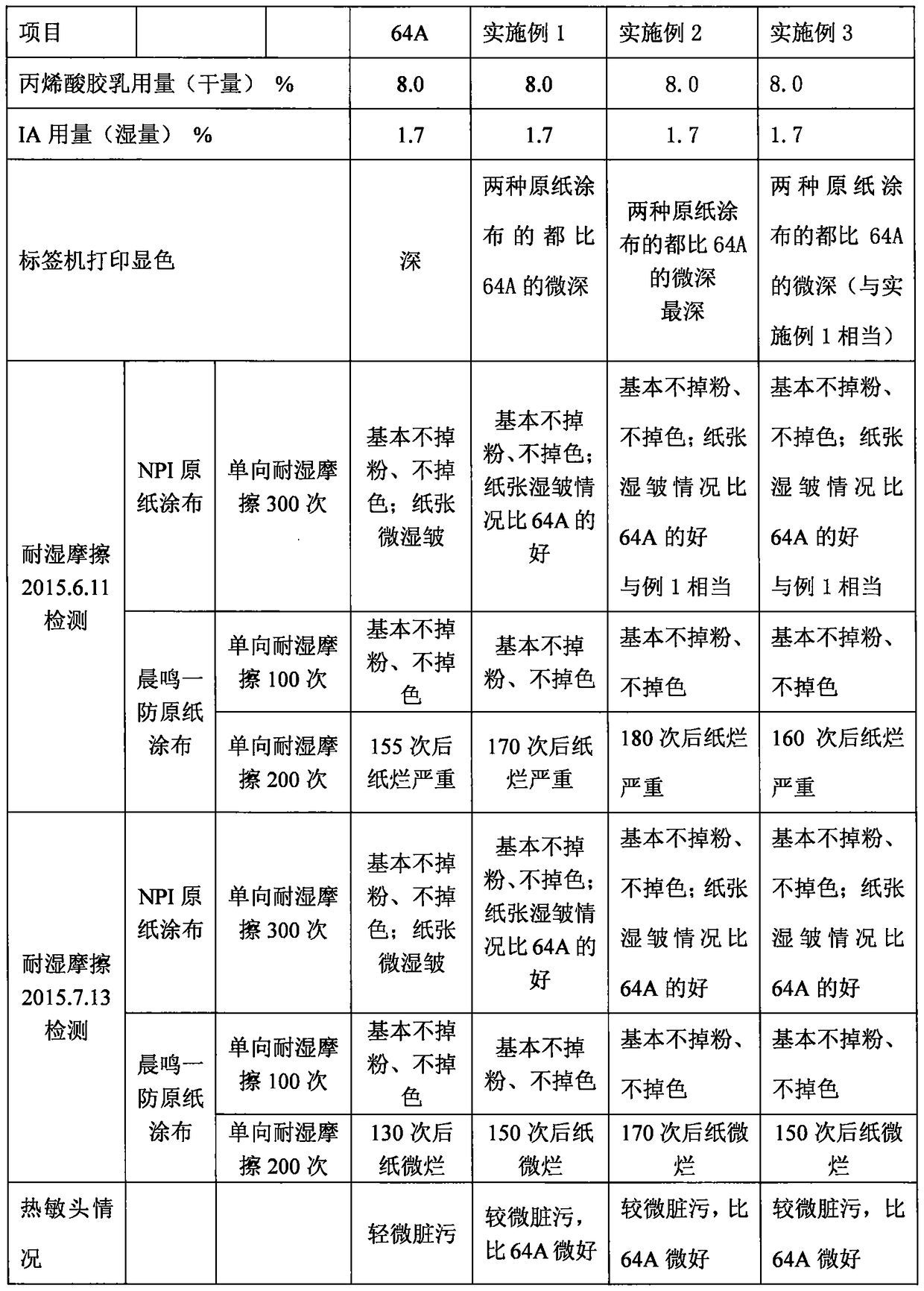

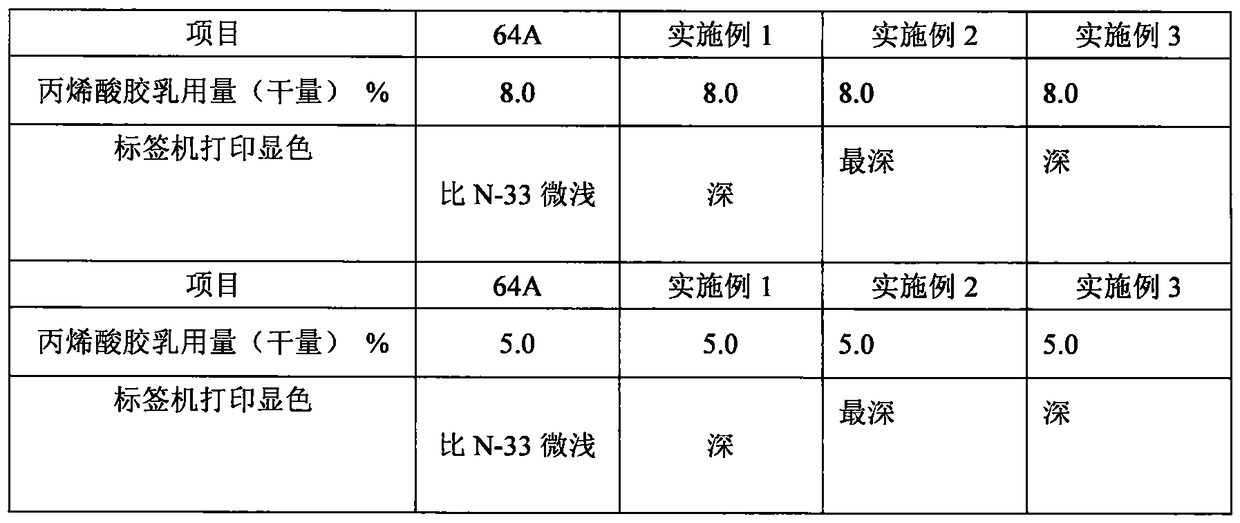

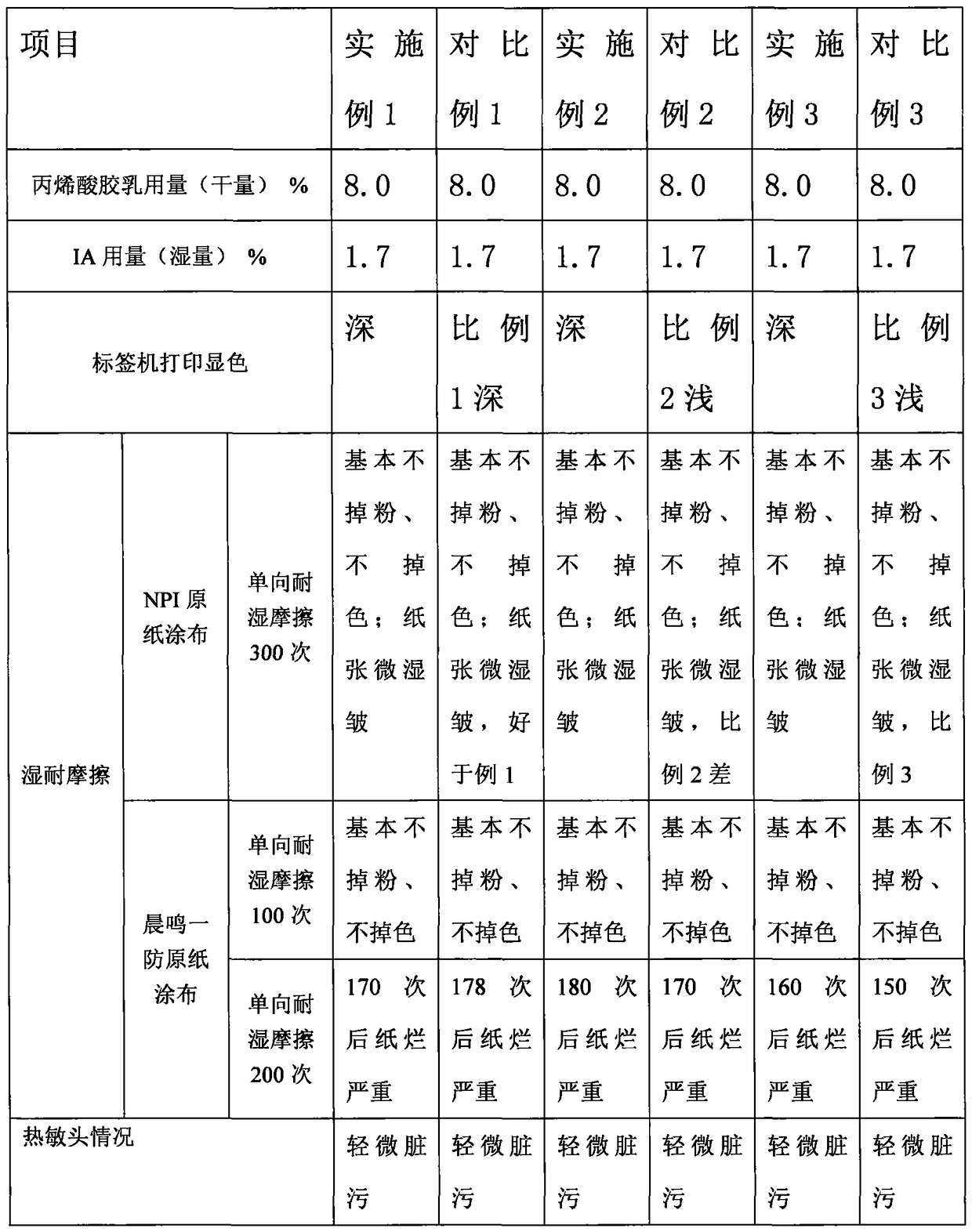

Examples

Embodiment 1

[0032] A coating adhesive for thermal copy paper, prepared by weight from the following components:

[0033] Butyl acrylate 50kg, methyl acrylate 5kg, methyl methacrylate 10kg, styrene 50kg, hydroxyethyl acrylate 3kg, glycidyl methacrylate 2kg, acrylic acid 4kg, methacrylic acid 4.5kg,

[0034] Diacetone acrylamide 3kg, adipic acid dihydrazide 2kg, octamethylcyclotetrasiloxane 5kg, methacryloxypropyltrimethoxysilane 1kg,

[0035] Allyloxy nonylphenol polyoxyethylene (10) ether monophosphoric acid 1.5kg, isomeric tridecyl alcohol polyoxyethylene ether 2kg, dodecyl mercaptan 0.02kg, ammonium bicarbonate 0.05kg, ammonium persulfate 0.2kg , Deionized water 200kg, ammonia water 10kg.

[0036] The specific steps of the preparation method are as follows:

[0037] (1) Add allyloxy nonylphenol polyoxyethylene (10) ether monophosphoric acid and isomeric tridecanol polyoxyethylene ether to 95% deionized water, dissolve completely at 50°C, and divide them into three parts on average ,s...

Embodiment 2

[0047] A coating adhesive for thermal copy paper, prepared by weight from the following components:

[0048] Butyl acrylate 65kg, methyl acrylate 6kg, methyl methacrylate 15kg, styrene 80kg, hydroxyethyl acrylate 3kg, glycidyl methacrylate 4kg, acrylic acid 5kg, methacrylic acid 6.5kg,

[0049] Diacetone acrylamide 6kg, adipic acid dihydrazide 4kg, octamethylcyclotetrasiloxane 7kg, methacryloxypropyl trimethoxysilane 2kg,

[0050] Allyloxy nonylphenol polyoxyethylene (10) ether monophosphoric acid 1.8kg, isomeric tridecyl alcohol polyoxyethylene ether (TO-40) 3kg, dodecyl mercaptan 0.03kg, ammonium bicarbonate 0.09kg, Ammonium persulfate 0.35kg, deionized water 260kg, ammonia water 18kg.

[0051] The specific steps of the preparation method are as follows:

[0052](1) Add allyloxy nonylphenol polyoxyethylene (10) ether monophosphoric acid and isomeric tridecanol polyoxyethylene ether to 95% deionized water, dissolve completely at 50°C, and divide them into three parts on ave...

Embodiment 3

[0062] A coating adhesive for thermal copy paper, prepared by weight from the following components:

[0063] Butyl acrylate 80kg, methyl acrylate 10kg, methyl methacrylate 20kg, styrene 100kg, hydroxyethyl acrylate 6kg, glycidyl methacrylate 4kg, acrylic acid 8kg, methacrylic acid 9kg,

[0064] Diacetone acrylamide 6kg, adipic acid dihydrazide 4kg, octamethylcyclotetrasiloxane 10kg, methacryloxypropyl trimethoxysilane 2kg,

[0065] Allyloxy nonylphenol polyoxyethylene (10) ether monophosphoric acid 3kg, isomeric tridecyl alcohol polyoxyethylene ether 4kg, dodecyl mercaptan 0.05kg, ammonium bicarbonate 0.1kg,

[0066] Ammonium persulfate 0.5kg,

[0067] Deionized water 300kg, ammonia water 20kg.

[0068] The specific steps of the preparation method are as follows:

[0069] (1) Add allyloxy nonylphenol polyoxyethylene (10) ether monophosphoric acid and isomeric tridecanol polyoxyethylene ether to 95% deionized water, dissolve completely at 50°C, and divide them into three par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com