Preparation method of potassium persulfate microcapsule gel breaker

A potassium persulfate and microcapsule technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of destroying the reservoir environment, reservoir conductivity, large industrial application requirements, and high preparation costs, achieving Increase the effect of popularization and applicability, good film formation and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and specific embodiments, and it is not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention should be included in the protection of the present invention. within range.

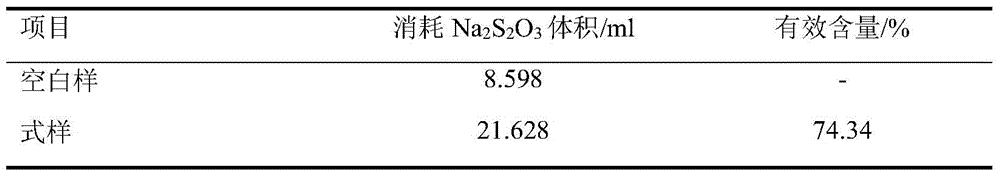

[0024] The potassium persulfate microcapsule gel breaker prepared by the present invention is tested for its gel breaking performance with water-based guar gum fracturing fluid. In the test process, in order to avoid the influence of other reagents, only guar gum is used as a thickener, cross-linked with borax, and used acetic acid Adjust the pH value.

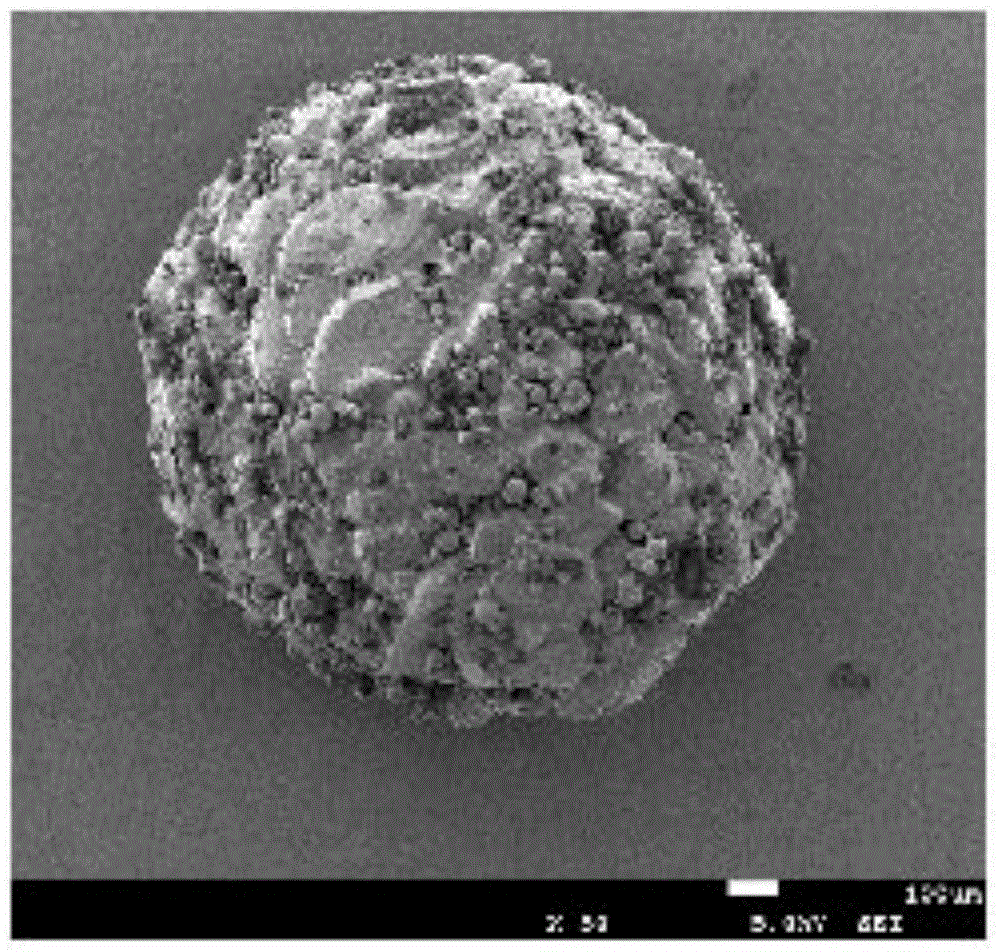

[0025] The embodiments of the present invention relate to directly adding the potassium persulfate solid powder core material to the continuous phase for the low water solubility of the core material at room temperature, while the clothing material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com