Method for preparing biodiesel by enhancing microorganisms in excess sludge to enrich and produce grease

A technology for excess sludge and biodiesel, which is applied in the field of sludge recycling, can solve problems such as unsatisfactory efficiency, and achieve the effects of high added value and improved carbon source conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

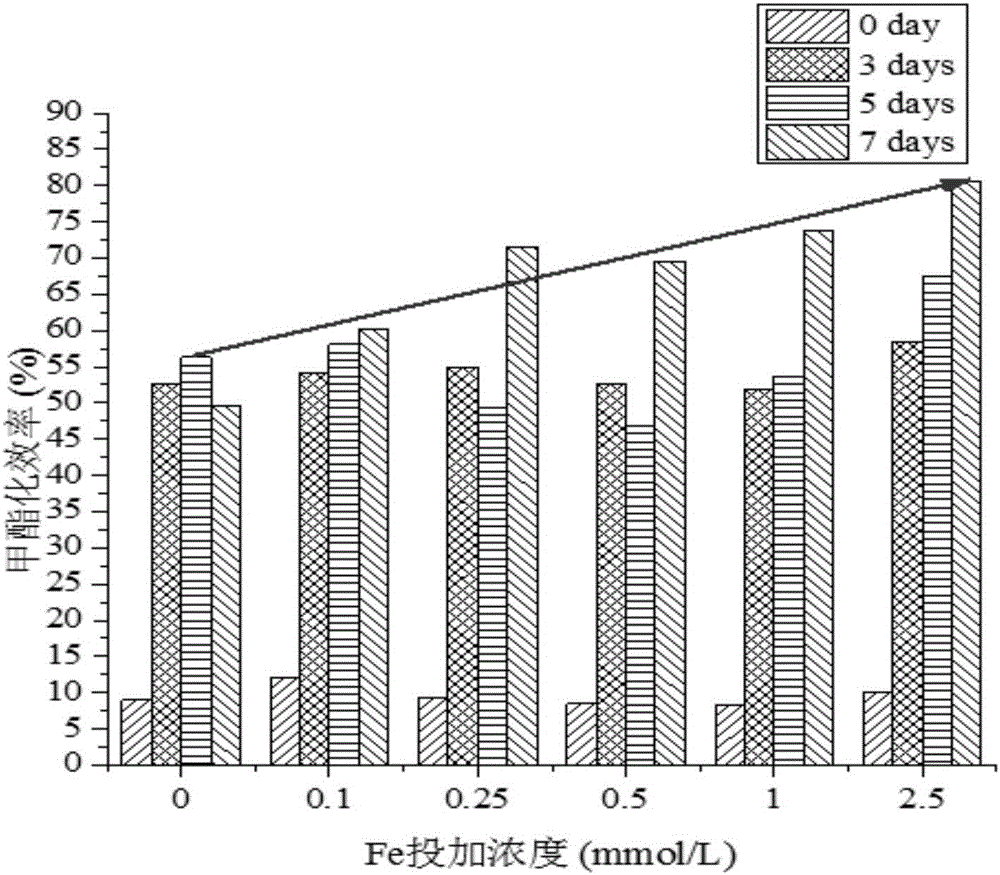

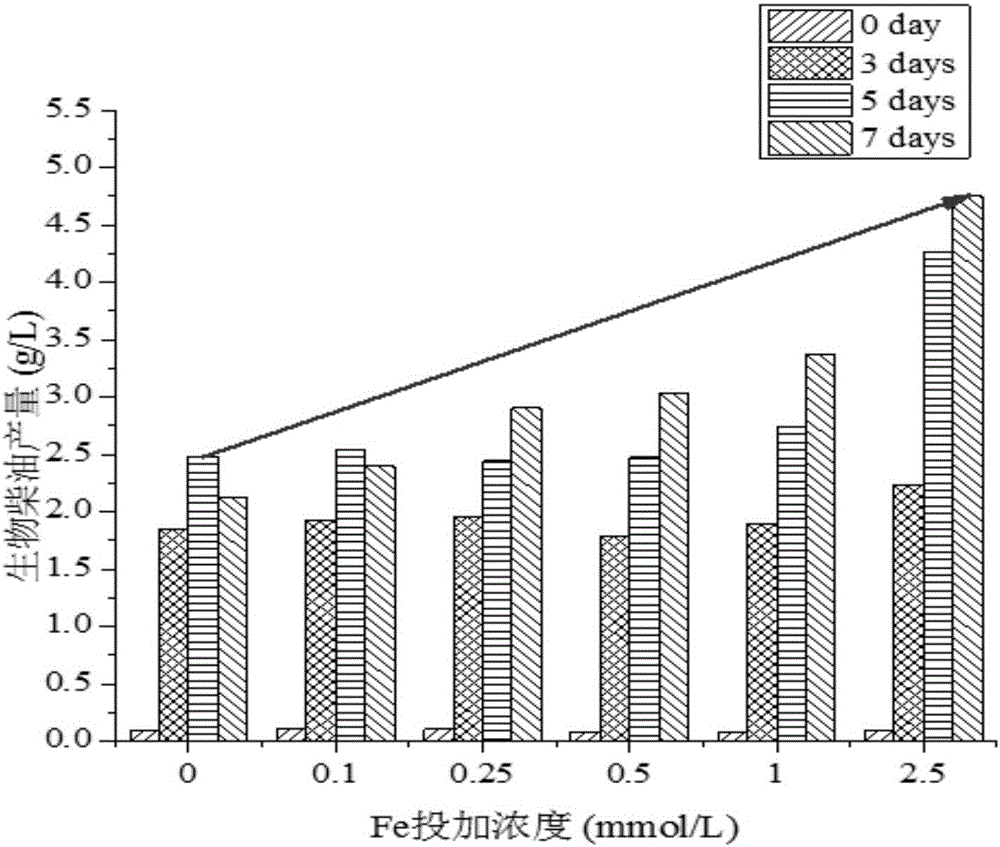

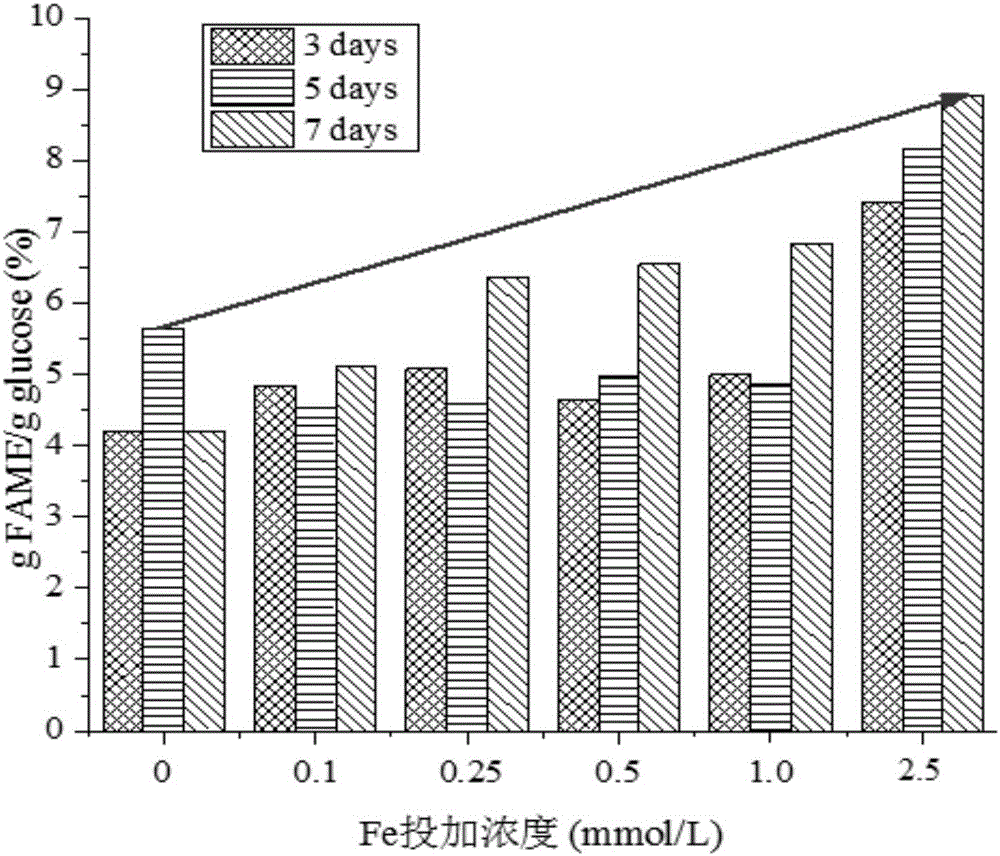

[0038] The invention discloses a method for preparing biodiesel by strengthening the enrichment and fat production of excess sludge microorganisms, the method comprising the following steps:

[0039] (1) Put the remaining sludge into the culture medium, add FeCl 3 Post-stirring fermentation: The influent of the sewage treatment plant is mainly domestic sewage, and some of it is industrial wastewater. The SBR process is adopted. The water quality indicators of the sewage treatment plant are as follows: COD cr =245.1mg / L, BOD 5 =86.1mg / L, SS=128.5mg / L, NH 3 -N=18.0 mg / L, COD / N=13.7, BOD / N=4.8, TP=2.22 mg / L, TN=30.0 mg / L. In the examples, after sampling, the sludge was concentrated at 4°C for 24 hours and then the supernatant was removed. The MLVSS (Volatile Suspended Solids, MixedLiquorVolatileSuspendedSolids) of the sludge after sedimentation and concentration was about 20g / L. The initial MLVSS after inoculation into the fermentation medium is about 2.0-3.0g / L.

[0040] The...

Embodiment 2

[0057] The method for preparing biodiesel by using the same method as in Example 1 to strengthen the enrichment of excess sludge microorganisms to produce fat, the difference is that the concentration of Fe in the culture medium before fermentation is 0.1mmol / L (as Fe 3+ count).

Embodiment 3

[0059] The method for preparing biodiesel by using the same method as in Example 1 to strengthen the enrichment of excess sludge microorganisms to produce fat, the difference is that the concentration of Fe in the culture medium before fermentation is 0.25mmol / L (as Fe 3+ count).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com