A kind of nitrogen-oxygen co-alloyed tizrhfnb-based high-entropy alloy and preparation method thereof

A nitrogen-oxygen co-alloy and high-entropy alloy technology, which is applied in the design of metal materials and its preparation, can solve problems such as insufficient strength and tensile properties of refractory high-entropy alloys, and achieve convenient preparation, wide composition range, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

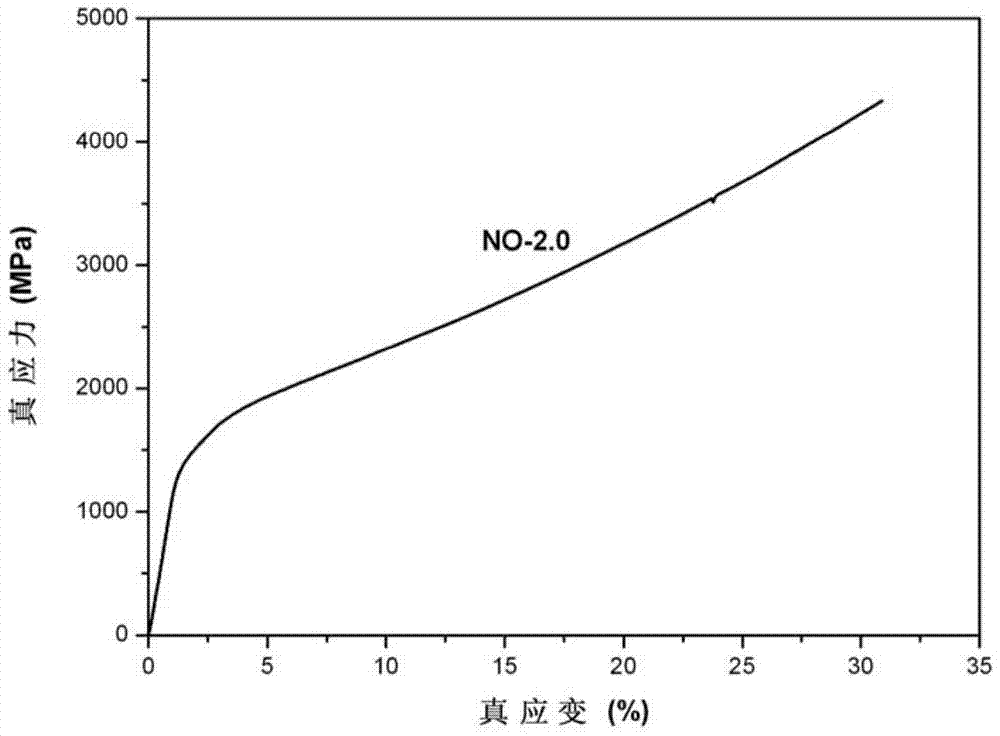

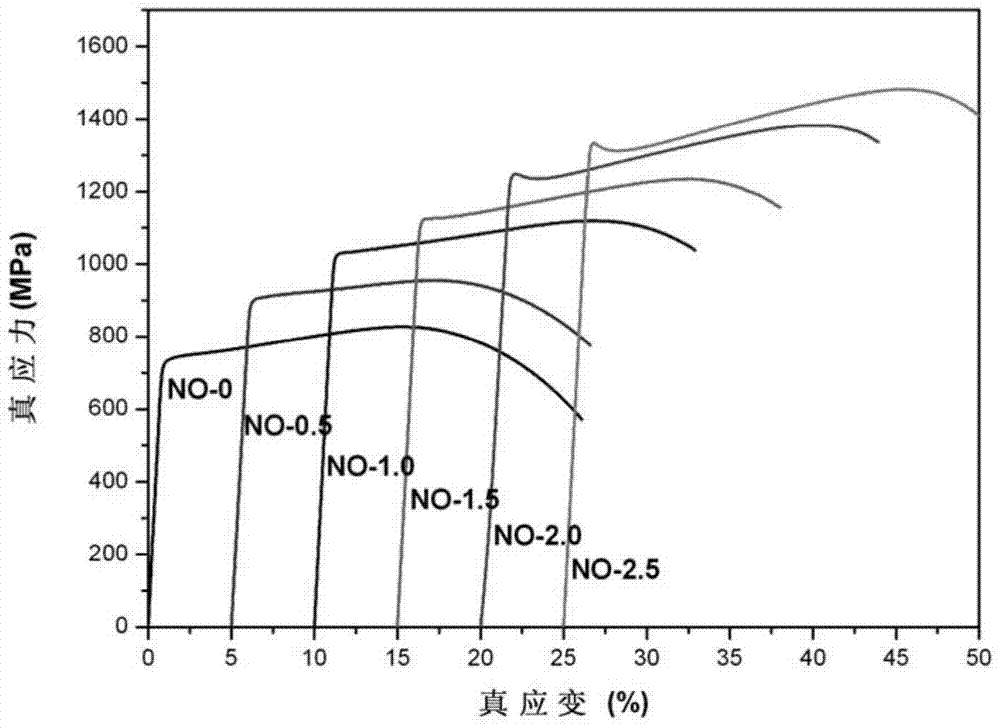

[0034] (TiZrHfNb) 100-x (NO) x Preparation and properties of high-entropy alloys

[0035] 1. Composition design and preparation of multi-principal refractory high-entropy alloys

[0036] The preparation process of TiZrHfNbNO high entropy alloy system is as follows:

[0037] (1) Raw material preparation: The smelting raw materials used in the present invention are high-purity (≥99.9%) Ti, Zr, Hf and Nb elements, remove the scale on the surface of the raw materials, weigh and proportion according to the molar ratio, and use ultrasonic waves in alcohol Oscillation and cleaning are used for smelting alloys. N element is directly added in the form of powder or bulk TiN, and O element is added in the form of powder or bulk TiO 2 form to join directly. Sources of Ti elements include high-purity Ti, TiN and TiO 2 , the total content of Ti element conforms to the nominal composition.

[0038] Table 1 Nominal composition (at%) of TiZrHfNbNO high-entropy alloy system

[0039]

...

Embodiment 2

[0058] (TiZrHfNb) 94 m 5 (NO) 1.0 Preparation and Properties of (M=Al, Ta, V)

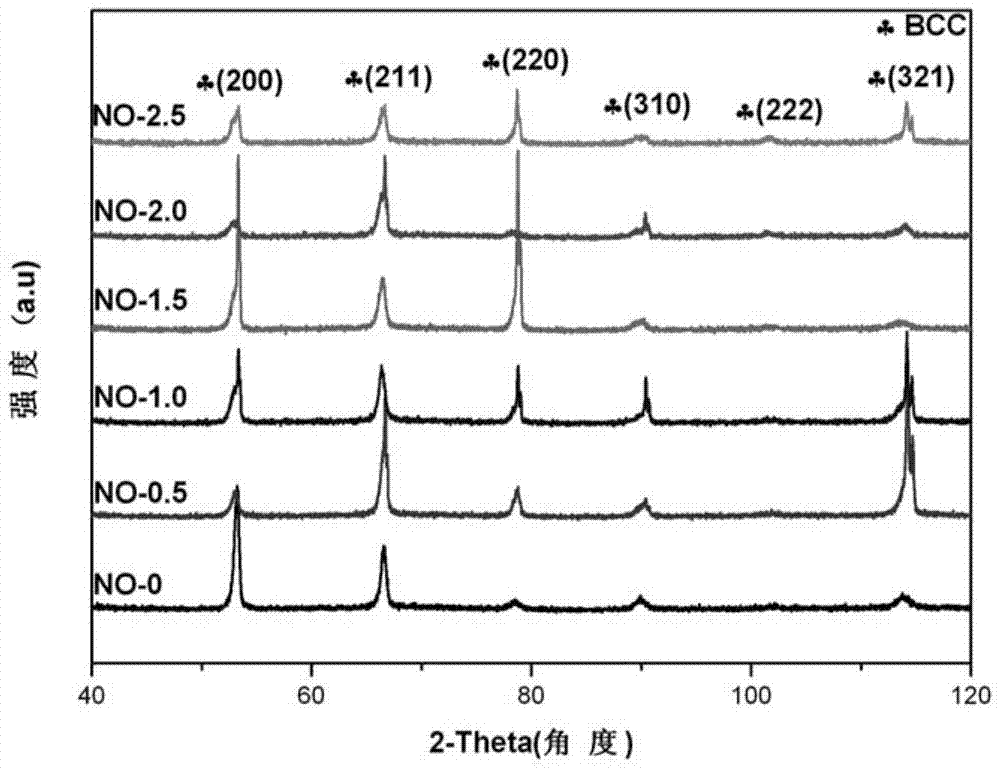

[0059] In the alloy system provided by the present invention, the doping of other alloy elements will significantly change the mechanical properties of the alloy. Figure 6 It is the XRD pattern of the TiZrHfNb-based high-entropy alloy with three different alloying elements added when the nitrogen and oxygen content is 1 at%. 1, 2, 3, 4 respectively correspond to (TiZrHfNb) 99 (NO) 1.0 , (TiZrHfNb) 94 al 5 (NO) 1.0 , (TiZrHfNb) 94 Ta 5 (NO) 1.0 , (TiZrHfNb) 94 V 5 (NO) 1.0 alloy. Among them, the abscissa is the 2θ angle, and the ordinate is the diffraction intensity (arbitrary unit). Contrast (TiZrHfNb) 99 (NO) 1.0It can be found that the addition of 5 at% Al, Ta, V did not change the single-phase BCC structure of the alloy. At the same time, we found that the addition of Al, Ta, and V significantly increased the intensity of the first diffraction peak, that is, significantly incr...

Embodiment 3

[0061] Part of the alloy composition and performance list studied by the present invention

[0062] According to the method of Example 1 and Example 2, TiZrHfNb-based high-entropy alloys with various ratios of nitrogen and oxygen co-alloying were prepared, and their composition and mechanical property parameters are listed in Table 3.

[0063] Table 3 Part of the alloy composition and tensile yield strength σ studied in the present invention y and tensile plastic ε p

[0064] Example

[0065] The invention innovatively simultaneously micro-alloys nitrogen and oxygen elements in the TiZrHfNb-based high-entropy alloy, significantly improves the yield strength and tensile strength of the TiZrHfNb-based high-entropy alloy, and can basically maintain the plastic deformation ability of the alloy system. In particular, the yield strength of NO-2.5 alloy reaches 1298MPa, the tensile strength reaches 1300MPa, and the elongation reaches 18.1%, which has excellent comprehensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com