Field electron emission device structure with reverse bias nano junction

A field electron emission and device structure technology, which is applied to electrical components, electrode devices and related components, cathode ray tubes/electron beam tubes, etc. volatility etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

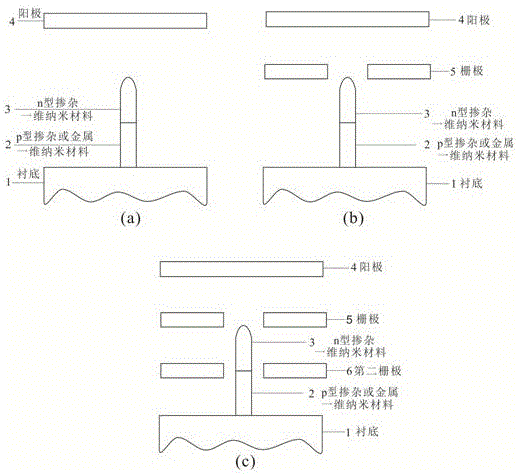

Method used

Image

Examples

Embodiment 1

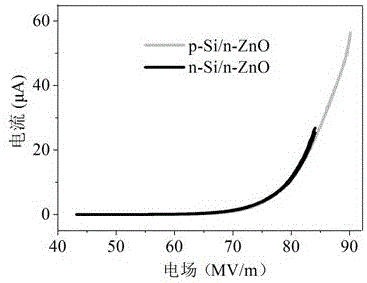

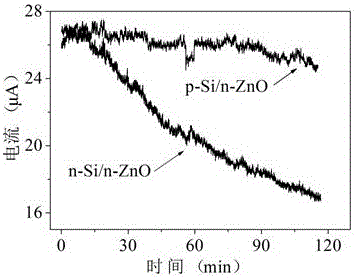

[0038] The preparation of the field electron emission device structure (single electrode, emitter: p-Si / n-ZnO) with the reverse bias nano-junction comprises the following steps:

[0039] S1. In P-type doping (10 19 cm -3 ) on the silicon wafer, using a magnetron sputtering deposition system to deposit a Zn seed layer with a thickness of 20 to 50 nm on its surface;

[0040] S2. Spin-coat electron beam photoresist (PMMA) with a thickness of about 500-650 nm;

[0041] S3. Using the electron beam exposure system to directly write the electron beam photoresist;

[0042] S4. developing the exposed sample to obtain a PMMA nanohole array template with a pitch of 4 μm, and the hole diameter is less than 200nm;

[0043] S5. Using the hydrothermal method (Zn 2+ 0.005mol / L, 80°C, 18h) to grow a one-dimensional ZnO nanostructure perpendicular to the substrate in the micropore, the method of growing ZnO refers to the patent application number 200710032889.1);

[0044] S6. Use ultrasoni...

Embodiment 2

[0049] The preparation of the field electron emission device structure (single electrode, emitter: p-Si / n-Si) with the reverse bias nano-junction comprises the following steps:

[0050] S1. Select the N-type doping (10 14 cm -3 ~10 18 cm -3 ) P-type doping of silicon semiconductor (10 19 cm -3 ~10 21 cm -3 ) a silicon semiconductor substrate, using a thin film deposition system to deposit a metal Cr layer with a thickness of about 50nm on its surface;

[0051] S2. Spin-coat negative electron beam photoresist (AR-N7520.18) with a thickness of about 400nm;

[0052] S3. Using an electron beam lithography system to perform pattern exposure on the photoresist;

[0053] S4. Develop the exposed sample by using a mixed solution of tetramethylammonium hydroxide (TMAH) and deionized water with a volume ratio of 4:1 to obtain a photoresist lattice pattern with a diameter of 100-200 nm;

[0054] S5. Using the photoresist lattice pattern as a mask, transfer the photoresist pattern...

Embodiment 3

[0060] The experimental method is the same as in Example 1 or 2, the only difference is that zinc oxide is replaced by N-type doped tin dioxide, ferric oxide, titanium oxide, tungsten oxide and other metal oxides or gallium nitride, indium phosphide, etc. any of the materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com