Ternary positive electrode material and preparation method therefor and lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of lithium-ion batteries, ternary positive electrode materials and their preparation, can solve the problems of poor rate performance and poor cycle stability, and achieve improved rate performance, reduced volume shrinkage, and improved cycle performance. Effects on stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] According to a preferred embodiment of the present invention, the Li 2 SiO 3 Coated in LiNi a co b mn c o 2 The outer surface of the material, this preferred embodiment can further improve the cycle stability and rate performance of the material.

[0022] The purpose of the present invention can be achieved as long as the ternary positive electrode material provided by the present invention has the aforementioned characteristics, and there is no special requirement for its preparation method. Any method that can prepare a ternary positive electrode material with the aforementioned characteristics and properties can be used in the present invention. For the present invention, the preferred ternary positive electrode material is prepared according to the following method, which method includes:

[0023] (1) Mix tetraethyl orthosilicate, organic solvent, water and Ni-Co-Mn ternary material precursor, then remove the organic solvent and water in the mixture obtained by...

Embodiment 1

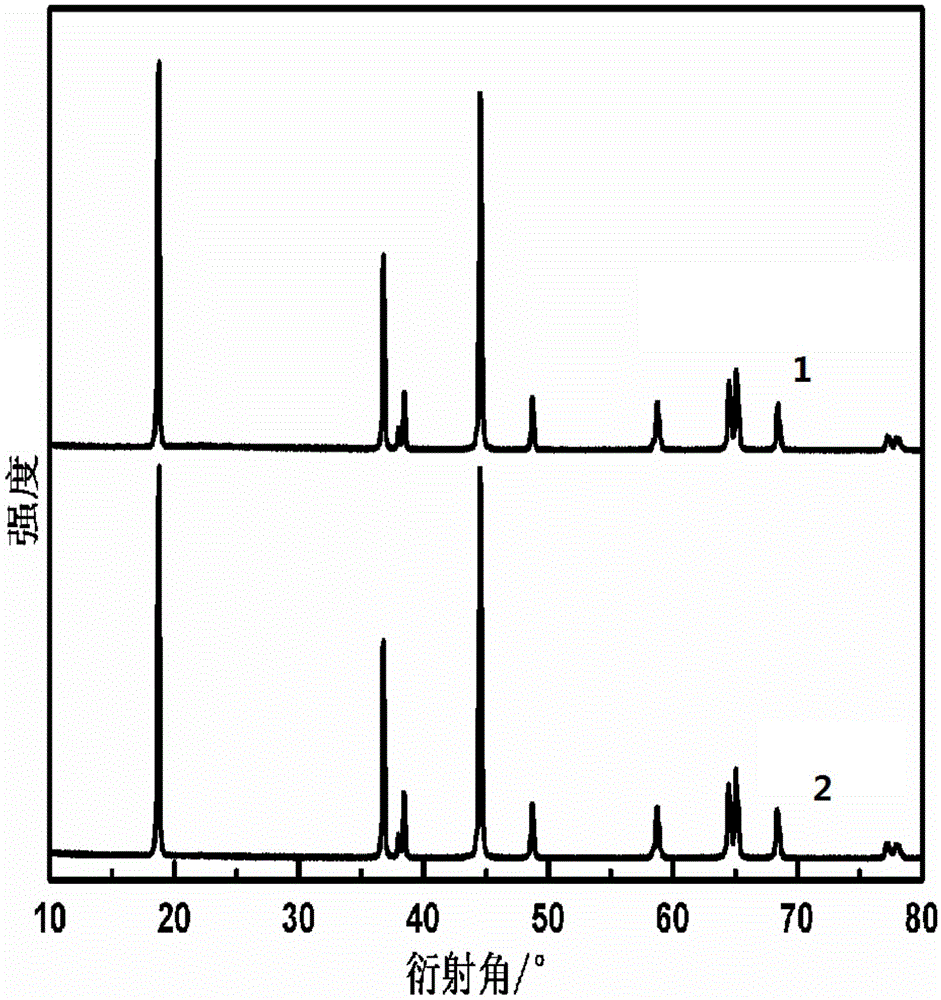

[0051] This example is used to illustrate the ternary cathode material of the present invention and its preparation method.

[0052] (1) Add 0.1g tetraethyl orthosilicate dropwise to 40ml ethanol aqueous solution (volume ratio of ethanol to water is 100:1), then add 1.5gNi 0.6 co 0.2 mn 0.2 (OH) 2 (Preparation by coprecipitation method), stirred at room temperature, then heated to 50°C and stirred for 350min, then dried at 75°C for 24h;

[0053] (2) Grind the solid matter obtained in step (1) with 0.65g of lithium carbonate evenly, place it in a tube furnace with an oxygen atmosphere for calcination, raise the temperature (heating rate 5°C / min) to 500°C, and treat it at a constant temperature for 3 hours , heating up (heating rate 5°C / min) to 850°C, and constant temperature treatment for 12h. After cooling down to room temperature, the ternary cathode material S-1 was obtained. Calculated according to the amount of feed, Li in S-1 2 SiO 3 The content of Li is 2.9 mol%; ...

Embodiment 2

[0068] This example is used to illustrate the ternary cathode material of the present invention and its preparation method.

[0069] (1) Add 0.3g tetraethyl orthosilicate dropwise to 40ml ethanol aqueous solution (the volume ratio of ethanol to water is 1:0.5), then add 1.5gNi 0.4 co 0.2 mn 0.4 (OH) 2 (Preparation by coprecipitation method), stirred at room temperature, heated to 60°C and stirred for 350min, then dried at 75°C for 24h;

[0070] (2) Grind the solid matter obtained in step (1) with 1.4 g of lithium nitrate evenly, place it in an air-atmosphere tube furnace for calcination, raise the temperature (heating rate 3°C / min) to 400°C, and treat it at a constant temperature for 6 hours , heating up (heating rate 5°C / min) to 950°C, and constant temperature treatment for 8h. After cooling down to room temperature, the ternary cathode material S-2 was obtained. Calculated according to the amount of feed, Li in S-2 2 SiO 3 The content of Li is 10 mol%, and Li 2 SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com