Method for preparing coarse cereal food based on single-screw extruder

A single-screw, miscellaneous grain technology, applied in the field of food processing, can solve the problems of overeating, lack of satiety, obesity and other problems, and achieve the effect of simple process, rich nutrition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw material processing: Use the stone removal sieving machine and magnetic iron remover to screen the corn raw materials to remove enzyme particles and stones, and obtain complete particles after selection.

[0031] Adding water to the material: use a mixer to mix the selected high-quality corn and purified water evenly at a mass ratio of 100:8.

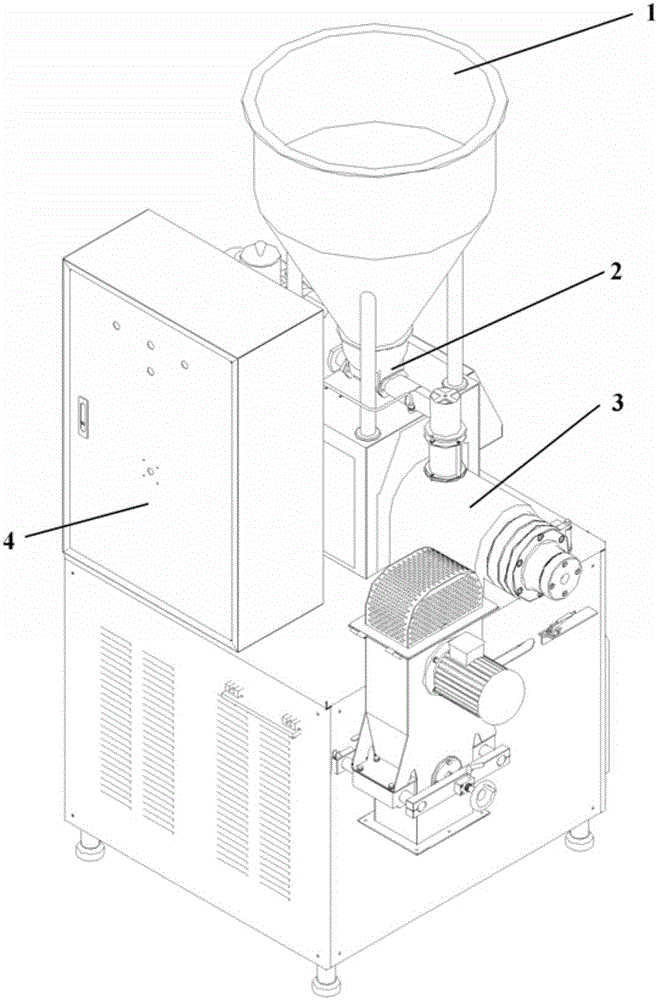

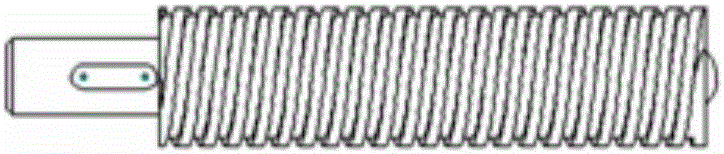

[0032] Single-screw extrusion: feed the mixed materials, and then perform screw extrusion through a single-screw extruder. The single-screw extruder uses a screw with a short length-to-diameter ratio of 1:4, and controls the rotation number of 500rmp to extrude to obtain flakes. product.

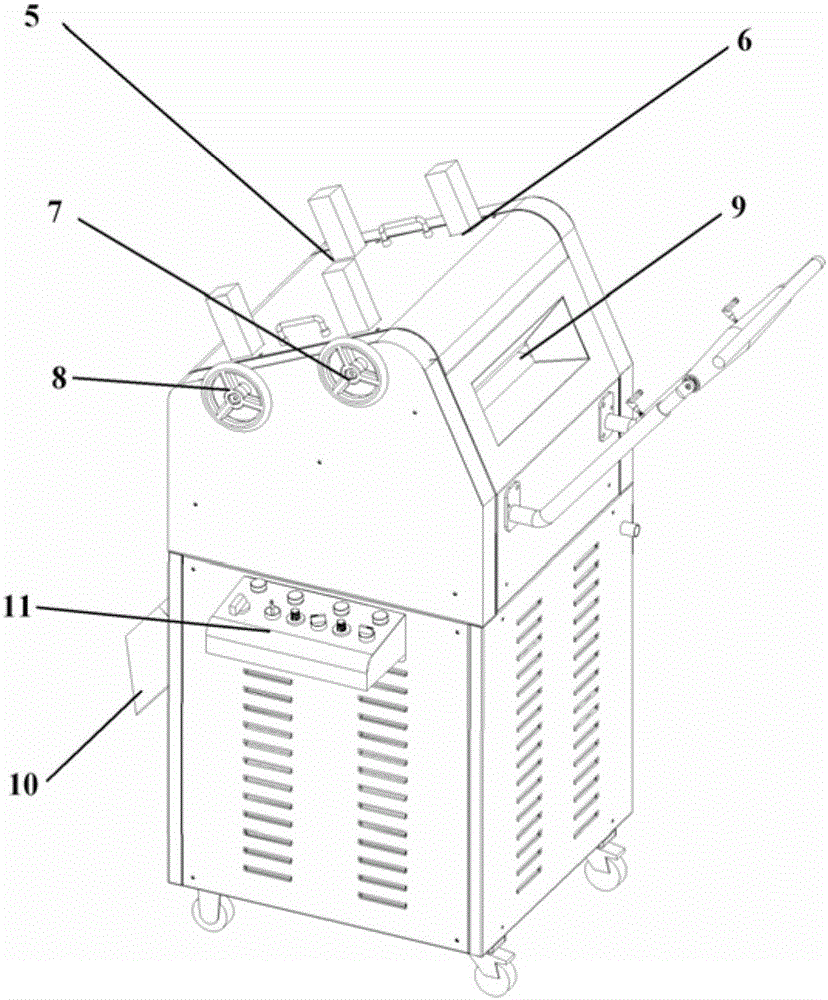

[0033] Cutting and forming: the extruded sheet material is connected to a forming cutting machine, firstly roll forming is performed to press the sheet material to an appropriate thickness, and then the product is rounded by cutting.

[0034] Baking or frying: The cut material is baked.

[0035] Seasoning packaging: packaging the baked pr...

Embodiment 2

[0037] Raw material processing: Use the stone removal sieving machine and magnetic iron remover to screen the buckwheat raw materials to remove enzyme particles and stones, and obtain complete particles after selection.

[0038] Adding water to the material: Stir the selected high-quality buckwheat and purified water with a mixer at a mass ratio of 100:6.

[0039] Single-screw extrusion: feed the mixed materials, and then perform screw extrusion through a single-screw extruder. The single-screw extruder uses a screw with a short length-to-diameter ratio of 1:4, and controls the rotation number of 600rmp to extrude into flakes. product.

[0040] Cutting and forming: The extruded sheet material is connected to a forming cutting machine, firstly roll forming is carried out to press the sheet material to an appropriate thickness, and then the product is made into a triangular shape by cutting.

[0041] Bake or fry: Fry the cut material.

[0042] Seasoning packaging: The fried pr...

Embodiment 3

[0044] Raw material processing: Use the stone-removing sieving machine and magnetic iron remover to screen the red bean raw materials to remove enzyme particles and stones, and obtain complete particles after selection.

[0045] Add water to the material: use a blender to stir the selected high-quality red beans and pure water according to the mass ratio of 100:9.

[0046] Single-screw extrusion: feed the mixed material, and then perform screw extrusion through a single-screw extruder. The single-screw extruder uses a screw with a short-to-length-to-diameter ratio of 1:4, and controls the rotation number of 400rmp to extrude to obtain flakes. product.

[0047] Cutting and forming: The extruded sheet material is connected to a forming cutting machine, firstly roll forming is performed to press the sheet material to an appropriate thickness, and then the product is cut into an animal shape.

[0048] Baking or frying: The cut material is baked.

[0049] Seasoning packaging: pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com