A slurry-bed nickel-based methanation catalyst prepared by precipitation combustion method and its application

A methanation catalyst, bed nickel-based technology, applied in the field of nickel-based catalyst preparation, can solve the problems of increasing production cost, small catalyst specific surface area, less catalyst surface active sites, etc., and achieves the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

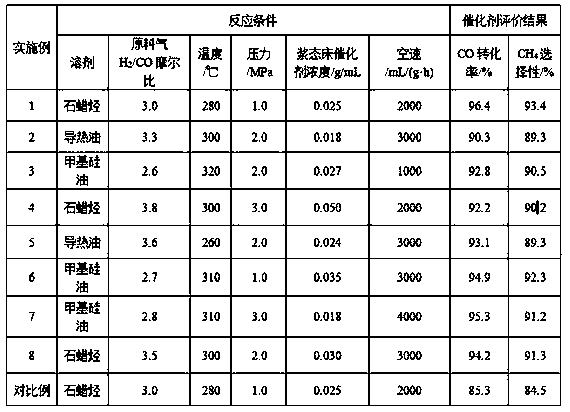

Examples

Embodiment 1

[0023] (1) Prepare an aluminum nitrate solution with a concentration of 1.0 mol / L, an aqueous solution of lanthanum nitrate with a concentration of 1.0 mol / L and a urea solution with a concentration of 5.0 mol / L. Adjust the adding rate of aluminum nitrate aqueous solution to 58.6 mL / min, the adding rate of lanthanum nitrate aqueous solution to 0.1 mL / min, and the adding rate of urea solution to 50.0 mL / min, so that the temperature is 75 ℃, and the stirring rate is 500 rpm in the reactor The precipitation in the medium was complete, and the addition was stopped after 2 h. During this process, the pH value of the solution was monitored with precision pH test paper, and the pH value of the solution was controlled to be 8.0.

[0024] (2) Keep the stirring rate constant, and at a temperature of 60 °C, add nickel nitrate aqueous solution with a solution concentration of 1.0 mol / L and urea aqueous solution with a solution concentration of 5.0 mol / L to the above suspension at the same...

Embodiment 2

[0028] (1) Prepare aluminum nitrate solution with a solution concentration of 1.0 mol / L, dysprosium nitrate aqueous solution with a solution concentration of 1.0 mol / L and urea solution with a solution concentration of 6.0 mol / L. Adjust the adding rate of aluminum nitrate aqueous solution to 17.1 mL / min, the rate of adding dysprosium nitrate aqueous solution to 0.2 mL / min, and the rate of adding urea solution to 50.0 mL / min, so that the temperature is 75 °C and the stirring rate is 400 rpm. The precipitation in the medium was complete, and the addition was stopped after 1 h. During this process, the pH value of the solution was monitored with precision pH test paper, and the pH value of the solution was controlled to be 8.0.

[0029](2) Keep the stirring rate constant, and at a temperature of 40 °C, add nickel nitrate aqueous solution with a solution concentration of 0.5 mol / L and urea aqueous solution with a solution concentration of 2.0 mol / L to the above suspension at the s...

Embodiment 3

[0033] (1) Prepare an aluminum nitrate solution with a concentration of 2.0 mol / L, an aqueous solution of lanthanum nitrate with a concentration of 0.5 mol / L and a urea solution with a concentration of 5.0 mol / L. Adjust the adding rate of aluminum nitrate aqueous solution to 21.2 mL / min, the adding rate of lanthanum nitrate aqueous solution to 0.5 mL / min, and the adding rate of urea solution to 50.0 mL / min, so that the reaction temperature is 80 °C and the stirring rate is 700 rpm. The precipitation in the vessel was complete, and the addition was stopped after 0.5h. During this process, the pH value of the solution was monitored with precision pH test paper, and the pH value of the solution was controlled to be 10.0.

[0034] (2) Keep the stirring rate constant, and at a temperature of 30 °C, add nickel nitrate aqueous solution with a solution concentration of 2.0 mol / L and urea aqueous solution with a solution concentration of 5.0 mol / L to the above suspension at the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com