Grass-moss-alga combined remediation technology for copper tailings

A combined restoration and copper tailings technology, applied in the restoration of contaminated soil, etc., can solve the problems of poor stability, labor, financial and material resources, and poor restoration effect, so as to improve copper tolerance and low restoration cost , the effect of avoiding soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention discloses a combined grass-moss-alga restoration technology for copper tailings. The restoration technology includes the following steps:

[0021] (1) Deep plow the copper tailings for 12-20 cm, and cover the soil with a thickness of 2-4 cm. Spray the algae culture solution on the surface of the soil, and the spraying ratio is 1000 grams of soil and copper Add 20-30ml of algae culture solution to the tailings sand;

[0022] (2) Carry out moss sowing simultaneously, moss sowing amount is to add moss 50g after natural drying in every 1000 grams of soil and copper tailings sand;

[0023] (3) Plant pasture plants after the algae-moss grows to cover and spray 30-40% of the soil area, the planting density is 4-5 rows per square meter, 10-20 plants in each row;

[0024] (4) After the algae, moss, and forage plants are planted, cover the planting soil with straw to keep moisture, and use ground irrigation, ordinary sprinkler irrigation or micro-irrigation to wate...

Embodiment 2

[0026] The purpose and method of the experiment: To screen the copper-resistant algae isolated from copper tailings soil, the specific method is as follows:

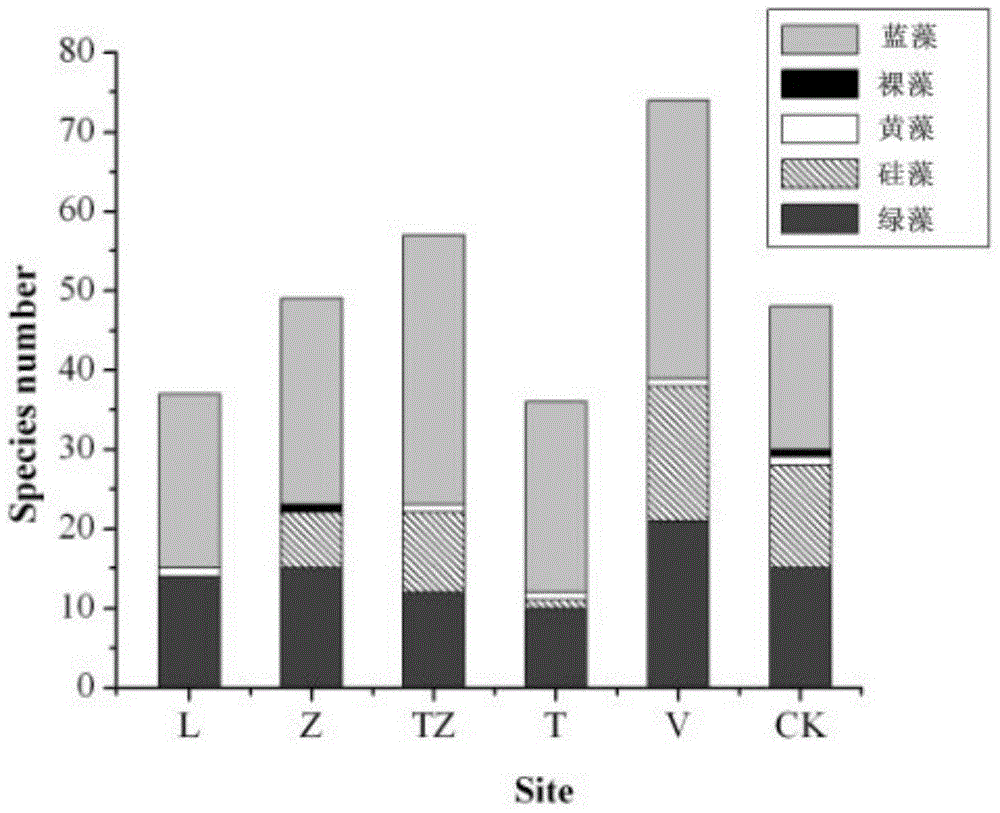

[0027] 1. Algae screening: Select bare land (L), algae crust (Z), moss-algae mixed crust (TZ), moss crust (T) and herbaceous preparation coverage area (V) as the early stage of copper tailings ecosystem For the succession series of plots, the herbaceous vegetation area (CK) with complete soil structure and rich species near the mountain was selected as the control point in the later stage of succession for algae screening.

[0028] 2. Algae culture: collect the above soil, make a soil suspension, inoculate on the prepared BBM solid medium, and cultivate in a sterile culture room for 3-4 weeks, the light intensity is about 3000-4000lx, and the light cycle is 16h (light) / 8h (dark). The indoor temperature was controlled at 25°C. After the algal colony grows, select a suitable dilution gradient plate (20-400 colonies / plate...

Embodiment 3

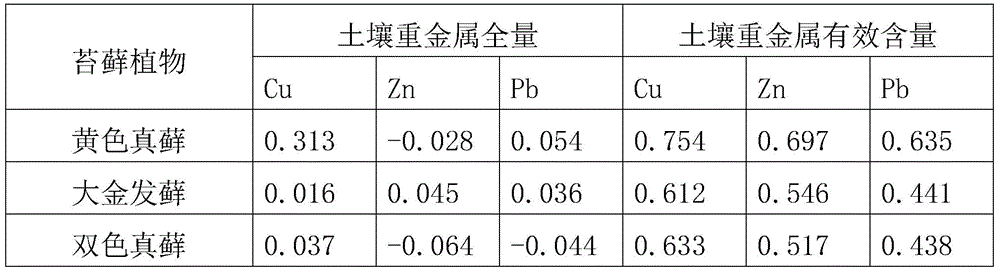

[0034] The purpose and method of the experiment: to screen the copper-resistant mosses in the restoration system, the specific method is as follows: respectively randomly select 5 locations in the moss biological crust as sampling points, take 3 samples repeatedly at each location, and divide the moss biological crust and The soil matrix in which it lives is retrieved together. Rinse the plant sample with distilled water to remove the soil and floating dust particles attached to the moss, blot the water on the sample with clean gauze, dry it in a drying oven at 70°C for 8-10 hours, and grind the sample with a ceramic mortar after drying , clean and sealed. After removing impurities, the tailings soil matrix samples were dried in a constant temperature oven at 85°C to constant weight, ground, sieved with a soil sieve (<1mm), and sealed in a desiccator. Weigh 0.2-0.5g of bryophyte sample, add 5ml of concentrated nitric acid to soak overnight, put it in an infrared digestion fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com