Wood modification chemical liquid and method for treating wood through wood modification chemical liquid

A technology of wood modification and liquid medicine, applied in wood treatment, wood treatment details, impregnated wood, etc., can solve the problem of release of small molecule volatiles, and achieve enhanced dimensional stability, excellent resistance to bacteria and decay, and sustainable sources. and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

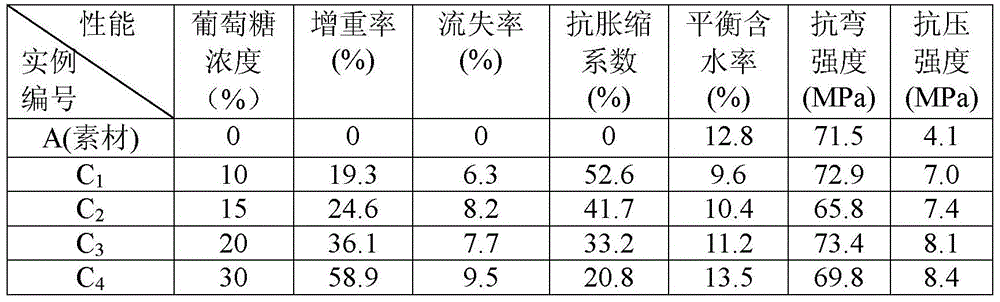

[0033] 1. Prepare modified liquid: add H to distilled water 2 o 2 , prepared into a 0.8M solution and stirred evenly, and then gradually added sucrose during the stirring process to form a transparent sucrose solution, wherein the added amounts of sucrose were 0%, 10%, 15%, 20% and 30% respectively. Adjust the pH value of the solution to 3.0, then slowly add 0.1M catalyst ferrous sulfate solution, stir evenly, add 0.2% sodium thiosulfate, stir for 1 hour, add 1.0% additive magnesium nitrate, stir evenly, and obtain the modifier solution.

[0034] 2. Vacuum pressure impregnation: adopt the vacuum pressure equipment used in traditional wood preservative treatment, and use the full cell method to make the modifier solution prepared in step 1 soak poplar (specification 2000 × 200 × 25mm 3 ), control the vacuum degree to -0.01MPa, the vacuum time is 1 hour, the pressure is 1.0MPa, and the holding time is 5 hours.

[0035] 3. Dry polymerization: The soaked poplar wood is first pl...

Embodiment 2

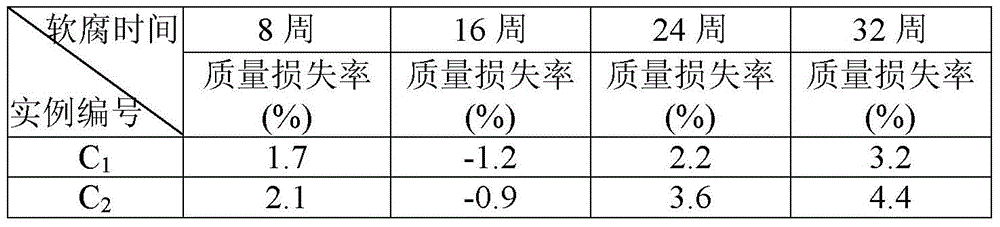

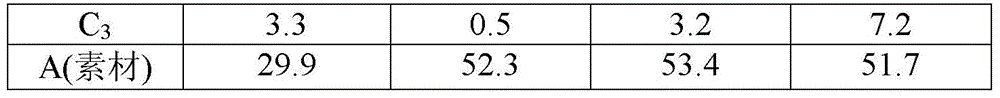

[0041] Modification process poplar according to the method of embodiment 1, subsequently untreated poplar (material) and modified poplar are placed in soft rot fungus environment simultaneously and accept anticorrosion performance test (test standard is European standard EN807), during the test Some samples were taken out at intervals to weigh the absolute dry mass, and the mass loss rate was calculated. The results are shown in Table 2. It can be seen from Table 2 that the mass loss rate of the poplar wood material after 32 weeks of testing was greater than 50%, while the highest mass loss rate of the three modified poplar woods was only 7%. This result shows that the modified wood prepared in Example 1 has excellent soft rot resistance, and can be used in environments that are in contact with soil, such as utility poles, wooden piles, and the like.

[0042] Table 2 Comparison of mass loss rate between untreated poplar (material) and modified poplar during soft rot

[0043] ...

Embodiment 3

[0046] 1. Prepare modified liquid: prepare 0M, 0.1M, 0.2M, 0.3M and 0.4M copper hydroxide suspensions, and then gradually add glucose during the stirring process, which corresponds to the concentration of glucose added to the concentration of copper hydroxide solution 0%, 5%, 10%, 15% and 20% to form a uniform solution. When the color of the solution becomes brick red, separate the precipitated cuprous oxide, add 1.5% magnesium nitrate to the obtained solution, and stir Uniformly, the modifier solution is prepared.

[0047] 2. Vacuum pressure impregnation: adopt the vacuum pressure equipment used in traditional wood preservative treatment, and use the full cell method to soak the modifier solution prepared in step 1 into radiata pine (specification 2000×200×25mm 3 ), control the vacuum degree to -0.01MPa, the vacuum time is 1 hour, the pressure is 1.0MPa, and the holding time is 5 hours.

[0048] 3. Dry polymerization: Put the soaked radiata pine in the atmosphere to dry natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com