Preparation method of layered nanoscale material

A layered nanomaterial, two-dimensional layered technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as polluted environment and complex preparation process, and achieve uniform morphology, The method is simple and easy to implement, and the structure is regular

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of CoP / graphene material, comprising the following steps:

[0033] (a) Add nitrile amine, rock sugar and cobalt trichloride in a molar ratio of 40:1:0.001 into deionized water at 95°C, and stir until completely dissolved to obtain a mixed solution;

[0034] (b) adding phosphoric acid to the mixed solution described in step (a), the molar ratio of phosphate radical and nitrile amine is 1:1, stirring until uniformly mixed, and then rotary evaporating and drying;

[0035] (c) In a tube furnace, under the protection of nitrogen, the temperature was raised to 600°C at 5°C / min, kept for 2 hours, then raised to 900°C at 5°C / min, kept for 2 hours, and taken out after cooling to obtain CoP / Graphene composites.

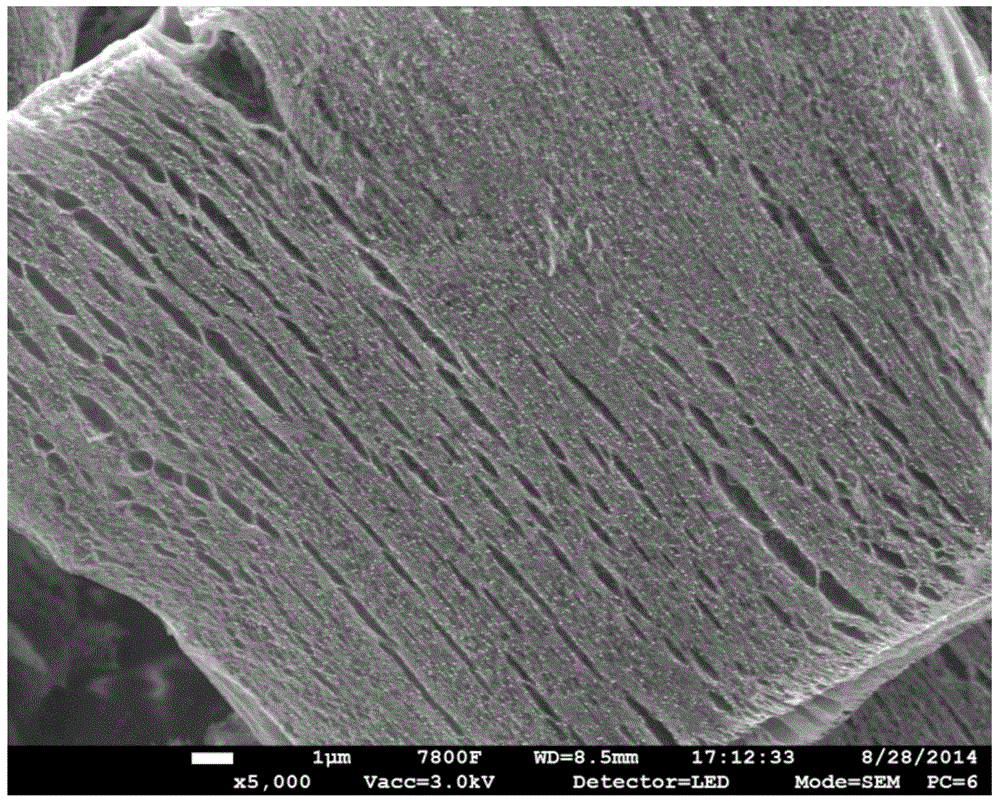

[0036] prepared materials such as figure 1 As shown, the material has a block structure macroscopically, the sheets are peeled off, and the load is on top of the sheets.

Embodiment 2

[0038] A preparation method of MoP / graphene material, comprises the following steps,

[0039] (a) Add urea, glucose and molybdenum pentachloride in a molar ratio of 30:1:0.05 into deionized water at 95°C, and stir until completely dissolved to obtain a mixed solution;

[0040] (b) Add phosphoric acid to the mixed solution described in step (a), the molar ratio of phosphate radical and urea is 1:0.5, stir until mixed evenly and then dry by rotary evaporation;

[0041] (c) In a tube furnace, under the protection of nitrogen, the temperature was raised to 600°C at 5°C / min, kept for 2 hours, then raised to 900°C at 5°C / min, kept for 2 hours, and taken out after cooling to obtain MnP / Graphene composites.

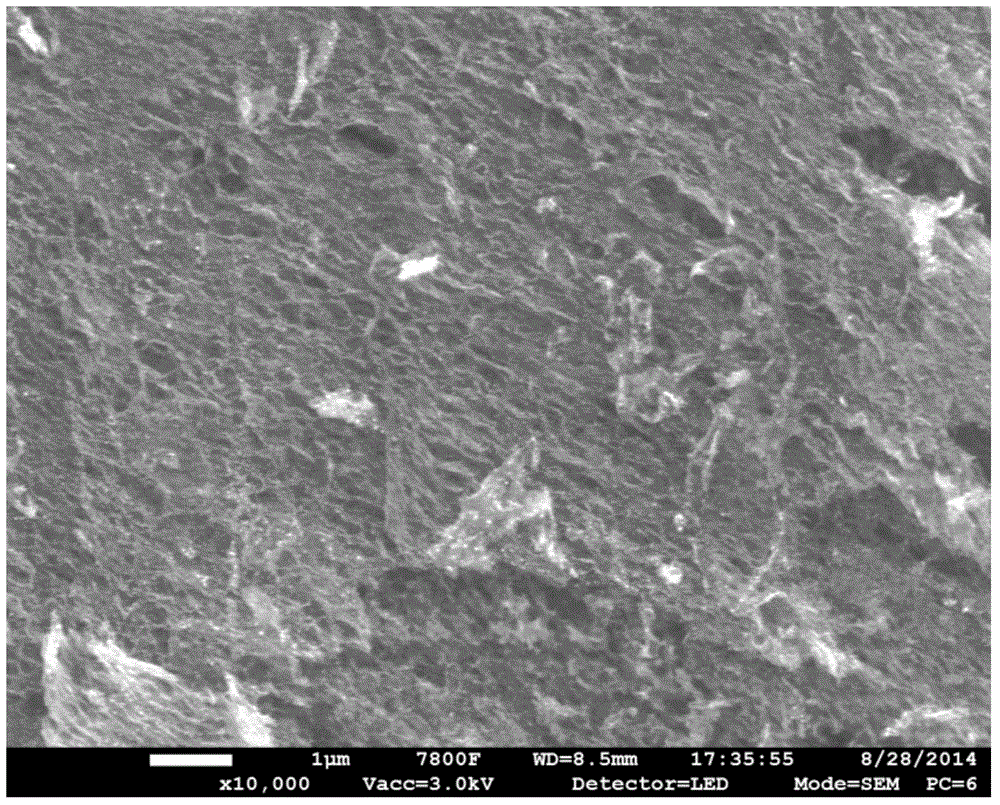

[0042] prepared materials such as figure 2 As shown, the material as a whole presents a neatly arranged exfoliated sheet structure, with uniform and fine nanoparticles loaded on it.

Embodiment 3

[0044] A kind of preparation method of NiP / graphene composite material, comprises the following steps,

[0045] (a) Add urea, glucose and nickel dichloride at a molar ratio of 30:1:0.05 to deionized water at 95°C, and stir until completely dissolved to obtain a mixed solution;

[0046] (b) Add phosphoric acid to the mixed solution described in step (a), the molar ratio of phosphate radical and urea is 1:0.5, stir until mixed evenly and then dry by rotary evaporation;

[0047] (c) In a tube furnace, under the protection of nitrogen, the temperature was raised to 600°C at 5°C / min, kept for 2 hours, and then raised to 900°C at 5°C / min, kept for 2 hours, cooled and taken out to obtain NiP / Graphene composites.

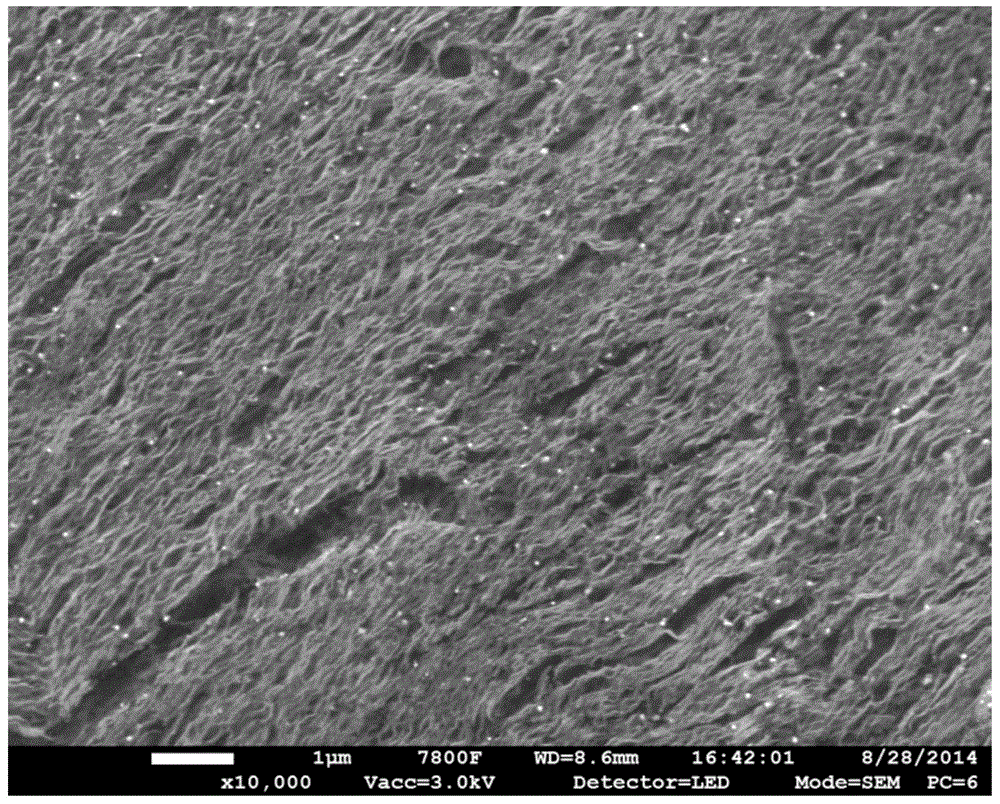

[0048] prepared materials such as image 3 As shown, the material as a whole presents a neatly arranged exfoliated sheet structure, with uniform and fine nanoparticles loaded on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com