Method for preparing yttrium lanthanum oxide transparent ceramic doped with Nd and Er

A technology of transparent ceramics, lanthanum yttrium oxide, applied in the field of special ceramics manufacturing process, can solve the problem of not considering the important influence of Nd

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

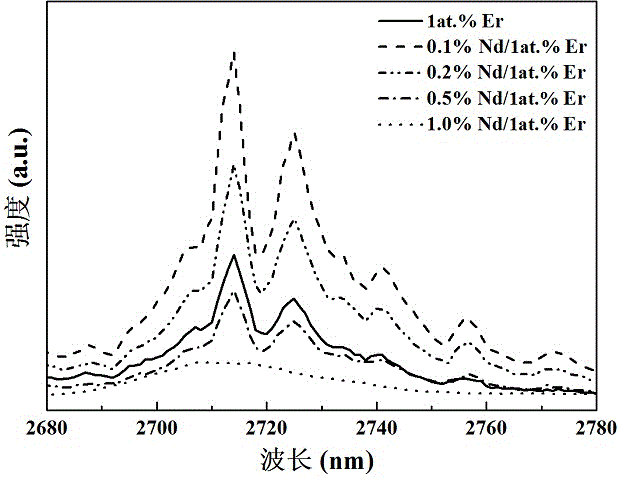

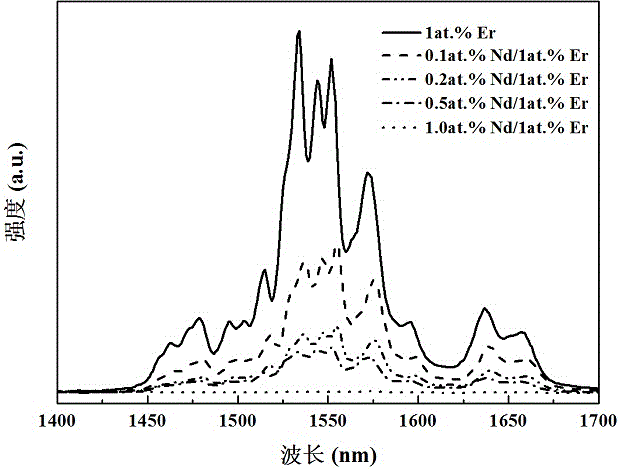

[0021] The present embodiment is a kind of preparation method of the lanthanum oxide yttrium transparent ceramics doped with Nd and Er, and its specific process steps are as follows:

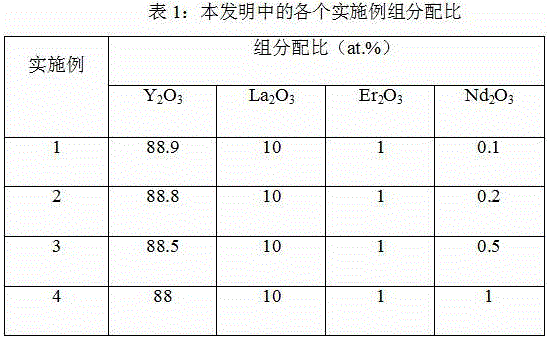

[0022] a. Using high-purity 99.99% Y 2 o 3 , 99.99%Er 2 o 3 , 99.99%Nd 2 o 3 and 99.99% La 2 o 3 as raw material; Y 2 o 3 is the matrix material; La 2 o 3 As a sintering aid, the dosing amount is 10at.%; Er 2 o 3 As an active ion, the doping amount is 1at.%; Nd 2 o 3 As a sensitizing ion, the doping amount is 0.1 at.%;

[0023] b. Stir the base material and the dopant material prepared according to the formula in step a, fully and evenly mix, and use ZrO in dehydrated alcohol for the mixture 2 Ball mill wet mixing for 5 hours;

[0024]c. Dry the mixture after mixing and grinding in step b at 90°C, then pre-calcine at 1200°C for 8-10 hours, and the calcination environment is air atmosphere, so as to obtain (Nd 0.001 Er 0.01 Y 0.889 La 0.1 ) 2 o 3 Powder;

[0025] d. Mix the...

Embodiment 2

[0030] The present embodiment is a kind of preparation method of the lanthanum oxide yttrium transparent ceramics doped with Nd and Er, and its specific process steps are as follows:

[0031] a. Using high-purity 99.99% Y 2 o 3 , 99.99%Er 2 o 3 , 99.99%Nd 2 o 3 and 99.99% La 2 o 3 as raw material; Y 2 o 3 is the matrix material; La 2 o 3 As a sintering aid, the dosing amount is 10at.%; Er 2 o 3 As an active ion, the doping amount is 1at.%; Nd 2 o 3 As a sensitizing ion, the doping amount is 0.2 at.%;

[0032] b. Stir the base material and the dopant material prepared according to the formula in step a, fully and evenly mix, and use ZrO in dehydrated alcohol for the mixture 2 Ball mill wet mixing for 5 hours;

[0033] c. Dry the mixture after mixing and grinding in step b at 90°C, then pre-calcine at 1200°C for 8-10 hours, and the calcination environment is air atmosphere, so as to obtain (Nd 0.002 Er 0.01 Y 0.888 La 0.1 ) 2 o 3 Powder;

[0034] d. Mix th...

Embodiment 3

[0039] The present embodiment is a kind of preparation method of the lanthanum oxide yttrium transparent ceramics doped with Nd and Er, and its specific process steps are as follows:

[0040] a. Using high-purity 99.99% Y 2 o 3 , 99.99%Er 2 o 3 , 99.99%Nd 2 o 3 and 99.99% La 2 o 3 as raw material; Y 2 o 3 is the matrix material; La 2 o 3 As a sintering aid, the dosing amount is 10at.%; Er 2 o 3 As an active ion, the doping amount is 1at.%; Nd 2 o 3 As a sensitizing ion, the doping amount is 0.5 at.%;

[0041] b. Stir the base material and the dopant material prepared according to the formula in step a, fully and evenly mix, and use ZrO in dehydrated alcohol for the mixture 2 Ball mill wet mixing for 5 hours;

[0042] c. Dry the mixture after mixing and grinding in step b at 90°C, then pre-calcine at 1200°C for 8-10 hours, and the calcination environment is air atmosphere, so as to obtain (Nd 0.005 Er 0.01 Y 0.885 La 0.1 ) 2 o 3 Powder;

[0043] d. Mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com