Fiber-reinforced ceramic matrix composite and preparation method for graphene/carbon nano-tube interface

A carbon nanotube and fiber-reinforced technology, which is applied in the field of connection involving a CVI process, can solve the problems of long interface phase period and poor dispersion, and achieve the effect of improving mechanical properties, good dispersion and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Disperse 0.5 g of carbon nanotubes in 1000 ml of deionized water, add 0.1 g of carbon nanotube aqueous solution dispersant, and then ultrasonically disperse for 30 min with an ultrasonic material emulsifying disperser to obtain a 0.5 mg / ml CNT aqueous solution.

[0047] (2) Disperse 0.5 g of graphene oxide into 500 ml of deionized water, disperse for 5 h with an ultrasonic cleaner, and prepare a 1 mg / ml graphene solution.

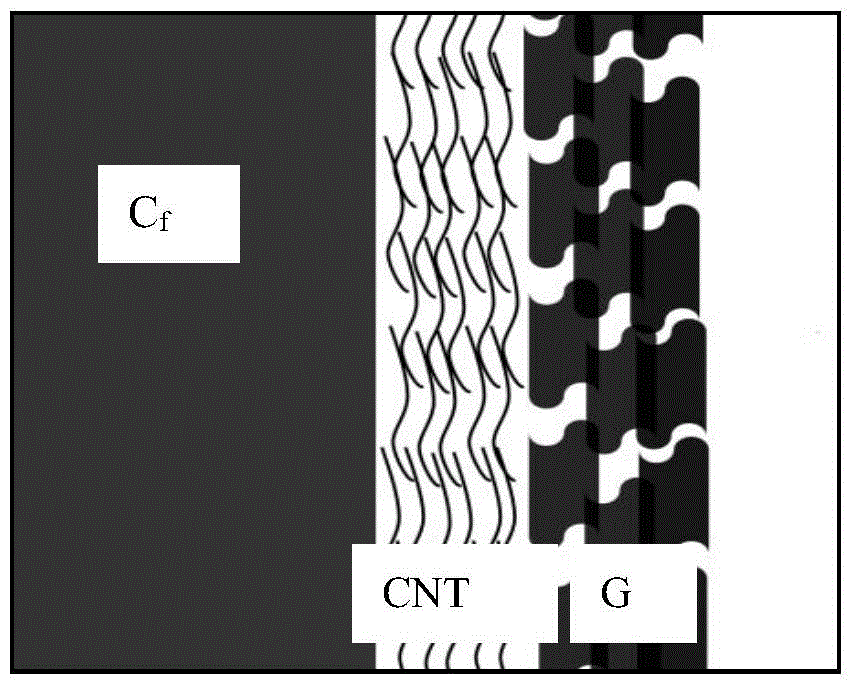

[0048] (3) Immerse the carbon fiber cloth in the CNT solution of step (1), electrophoretically deposit the CNT for 15 minutes, take it out and dry it; then immerse the carbon fiber in the graphene solution of the step (2), electroreduce the deposited graphene for 15 minutes, take it out and dry it ; Obtain carbon fiber cloth with CNT / GO interface

[0049] (4) Laminate 20 sheets of carbon fiber cloth prepared in step (3), clamp and shape them with two porous graphite plates, and sew the template and the laminated carbon cloth in the middle by the ...

Embodiment 2

[0054] (1) Disperse 0.5 g of carbon nanotubes in 1000 ml of deionized water, add 0.1 g of carbon nanotube aqueous solution dispersant, and then ultrasonically disperse for 30 min with an ultrasonic material emulsifying disperser to obtain a 0.5 mg / ml CNT aqueous solution.

[0055] (2) Disperse 0.5 g of graphene oxide into 500 ml of deionized water, disperse for 5 h with an ultrasonic cleaner, and prepare a 1 mg / ml graphene solution.

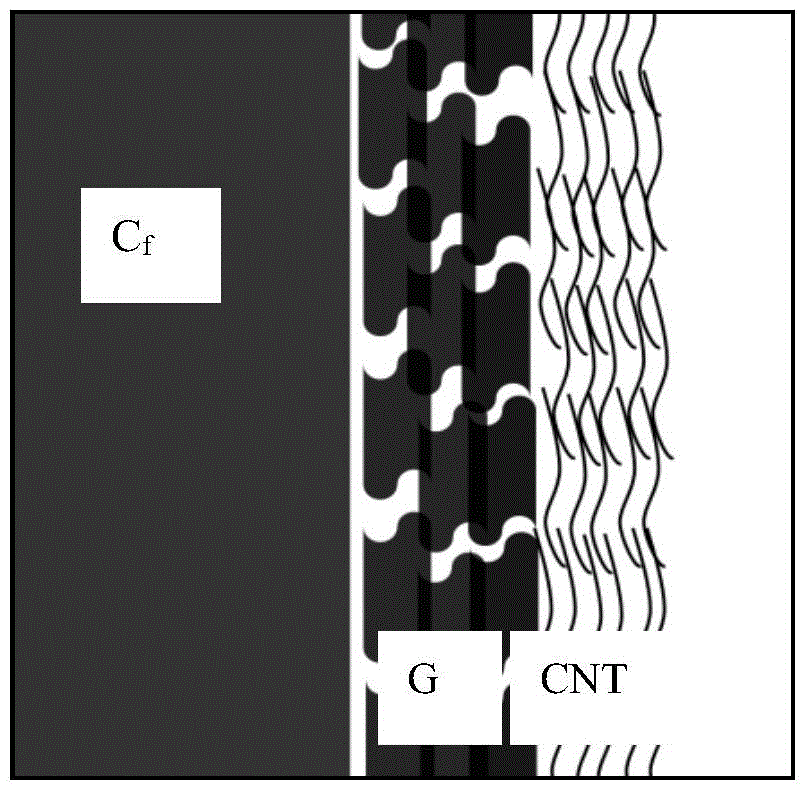

[0056] (3) Immerse carbon fiber in the graphene solution of step (2), electroreductively deposit graphene for 15 minutes, take out and dry; then immerse carbon fiber cloth in the CNT solution of step (1), deposit CNT by electrophoresis for 15min, take out and dry; Carbon fiber cloth impregnated with GO / CNT interface was obtained.

[0057] (4) Laminate 20 sheets of carbon fiber cloth prepared in step (3), clamp and shape them with two porous graphite plates, and sew the template and the laminated carbon cloth in the middle by the relay-type acupun...

Embodiment 3

[0062] (1) Disperse 0.5 g of carbon nanotubes in 1000 ml of deionized water, add 0.1 g of carbon nanotube aqueous solution dispersant, and then ultrasonically disperse for 30 min with an ultrasonic material emulsifying disperser to obtain a 0.5 mg / ml CNT aqueous solution.

[0063] (2) Disperse 0.5 g of graphene oxide into 500 ml of deionized water, disperse for 5 h with an ultrasonic cleaner, and prepare a 1 mg / ml graphene solution.

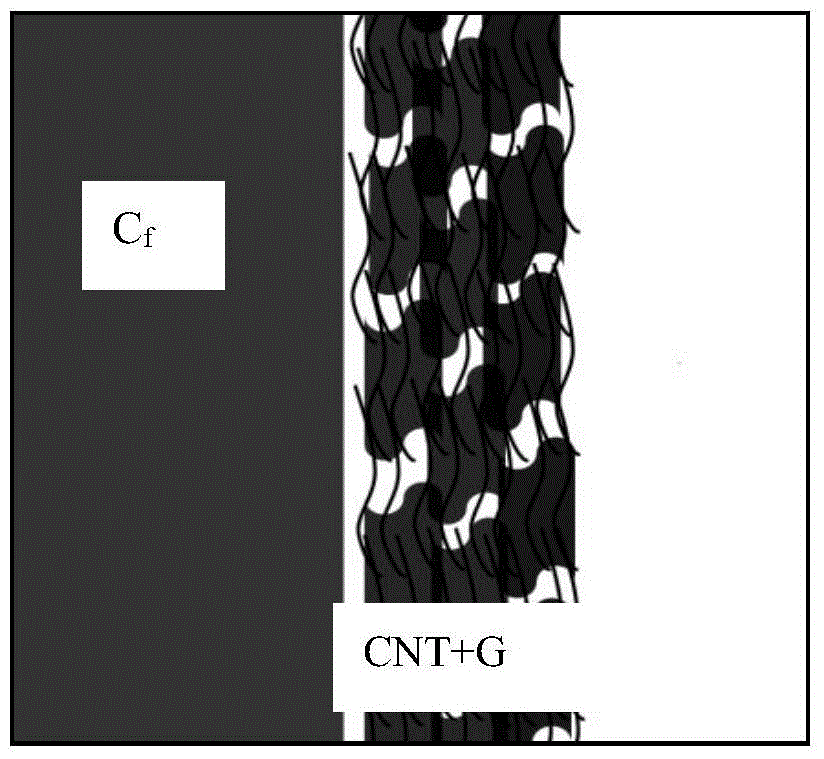

[0064] (3) Mix the solution configured in step (1) with step (2) to obtain a CNT / GO mixed solution.

[0065] (4) Immerse the 1K carbon fiber bundles in the CNT / GO mixed solution in step (3), electrify for 30 minutes, take them out and dry them in the air to obtain carbon fiber bundles with CNT / GO interfaces deposited.

[0066] (5) On the 1K carbon fiber bundle obtained in step (4), a CVI process is used to deposit a SiC substrate. The process conditions are as follows: trichloromethylsilane is the precursor gas, argon is the dilution gas (flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com