A kind of preparation method of paraffin-containing fuel

A technology of paraffin fuel and paraffin, which is applied in the field of solid-liquid hybrid engine propellant preparation, can solve the problems of low dropping point and poor mechanical properties of paraffin-containing fuels, and achieve the effects of improving mechanical properties, increasing dropping point, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This embodiment is a method for preparing paraffin-containing fuel.

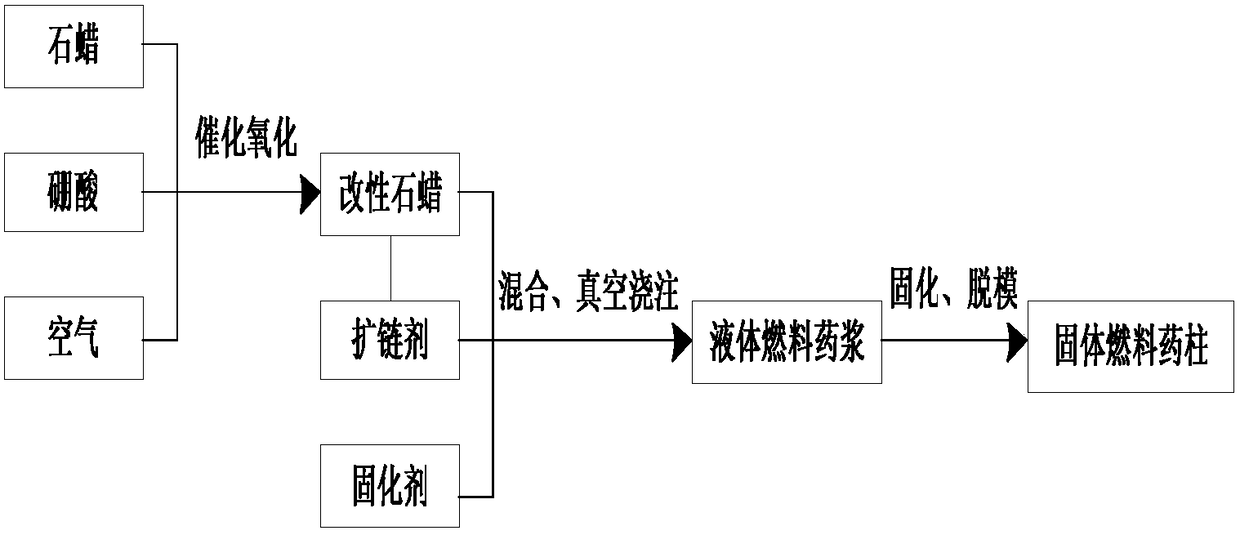

[0027] Refer to figure 1 , The preparation method of paraffin-containing fuel in this embodiment, the specific process is:

[0028] The first step. Modification of paraffin wax;

[0029] It is generally believed that the catalytic oxidation of paraffin wax follows the free radical chain theory, which can only be carried out under the action of a catalyst or initiator; once peroxide is formed, the chain reaction begins. The peroxide can further generate acid, ketone, and alcohol organic compounds in contact or non-contact. When boric acid is present in paraffin wax, boric acid not only catalyzes the decomposition of peroxide, but also makes it directionally decompose to produce alcohol, and it can also prevent the further oxidation of the produced alcohol; using boric acid as a catalyst, paraffin and air As the main raw material, it introduces hydroxyl groups into paraffin wax molecules through catalytic o...

example 1

[0044] Heat 250g of paraffin wax to 210°C, then pass in air with a flow rate of 3L / min, and slowly add 21g of boric acid while maintaining the temperature at 200°C. After adding boric acid for 1 hour, perform vacuum distillation at a temperature of 180°C and a pressure of 10 Pa. Pour the residue after vacuum distillation into hot water at a temperature of 80°C and a volume of 600 ml, and stir for 30 minutes. The upper material is vacuum dried to obtain modified paraffin wax.

[0045] Take 50% modified paraffin wax, 12% tris(2-methyl-1-aziridine) phosphine oxide, and 38% hydroxyl-terminated polybutadiene according to mass percentage to weigh each raw material. First put the modified paraffin wax in a mixing pot with a temperature of 60°C. After the modified paraffin wax is melted, add tris(2-methyl-1-aziridine) phosphine oxide and hydroxy-terminated polybutadiene in sequence according to the formula, and stir Mix for 45 minutes. The mixed liquid slurry is vacuum poured at a temp...

example 2

[0047] Heat 250g of paraffin wax to 210°C, then pass in air with a flow rate of 3L / min, and slowly add 21g of boric acid while maintaining the temperature at 200°C. After adding boric acid for 1 hour, perform vacuum distillation at a temperature of 180°C and a pressure of 10 Pa. Pour the residue after vacuum distillation into hot water at a temperature of 80°C and a volume of 600 ml, and stir for 30 minutes. The upper material is vacuum dried to obtain modified paraffin wax.

[0048] Weigh 35% of modified paraffin wax, 10% of tris(2-methyl-1-aziridine) phosphine oxide, 25% of hydroxyl-terminated polybutadiene, and 30% of elemental aluminum according to mass percentage. First put the modified paraffin wax in a mixing pot with a temperature of 60°C, after the modified paraffin is melted, add tris(2-methyl-1-aziridine) phosphine oxide, hydroxyl-terminated polybutadiene and elemental substances in sequence according to the formula Aluminum, stir and mix for 45 minutes. The mixed li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com