Silicon dioxide-methyl methacrylate composite aerogel material based on surface modification and preparation method thereof

A technology of methyl methacrylate and composite airgel, which is applied in the field of green building materials to achieve the best thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

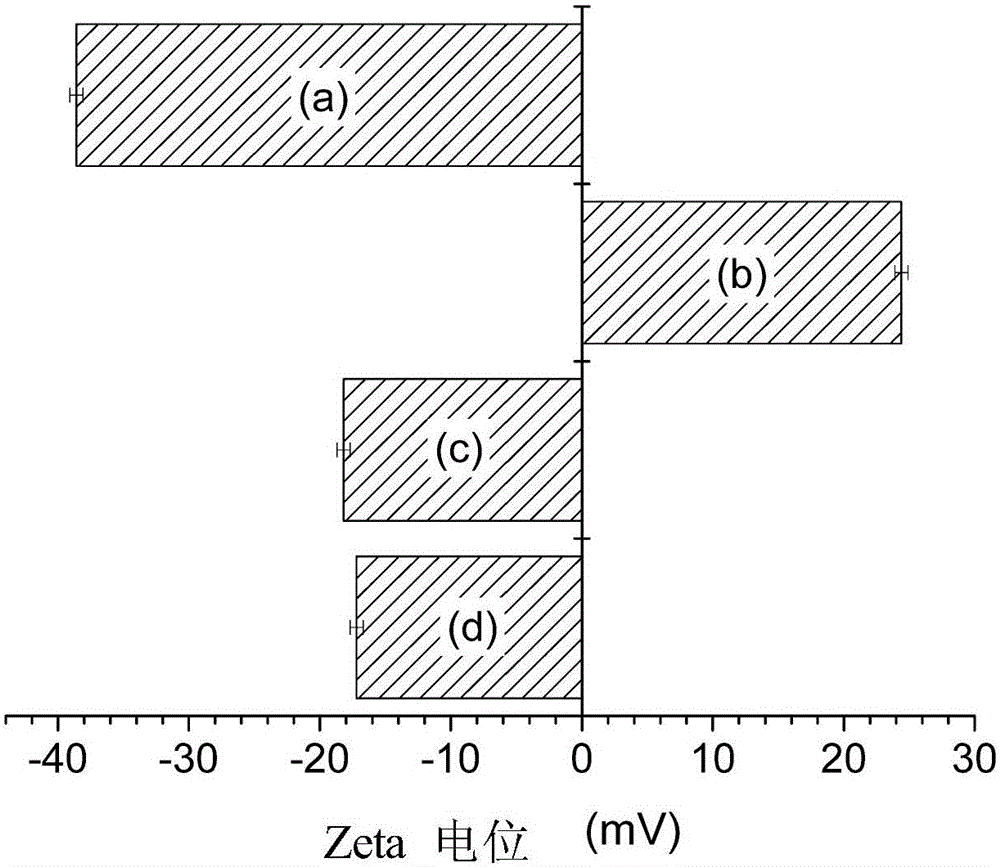

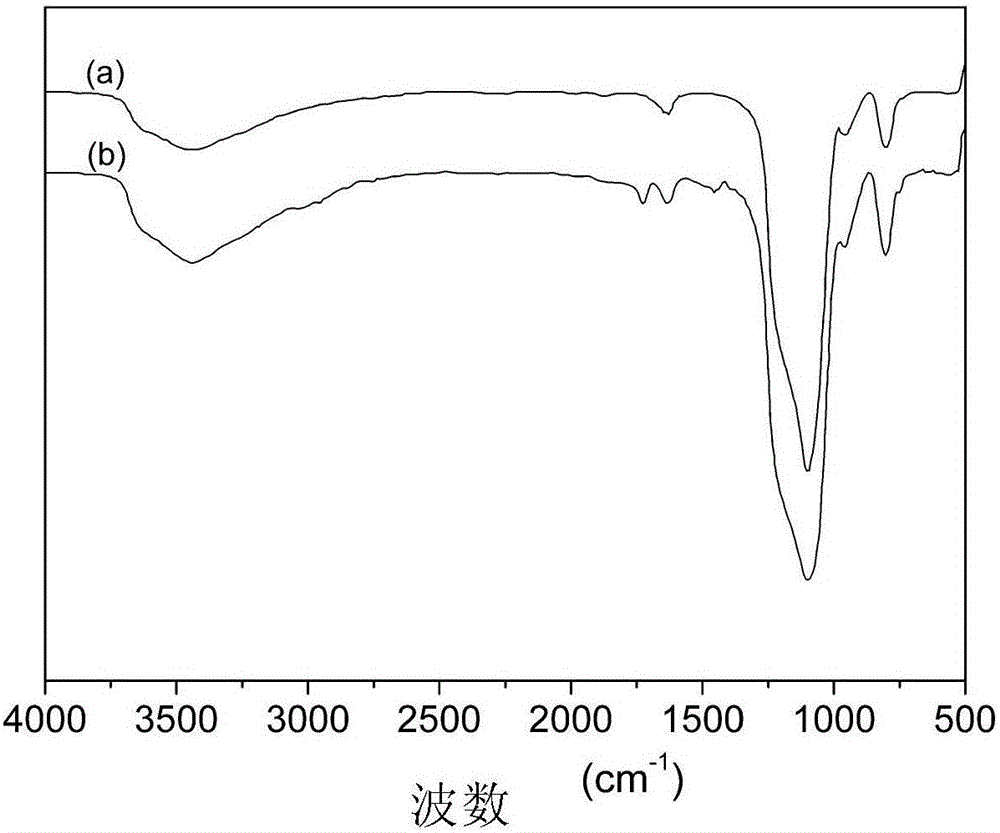

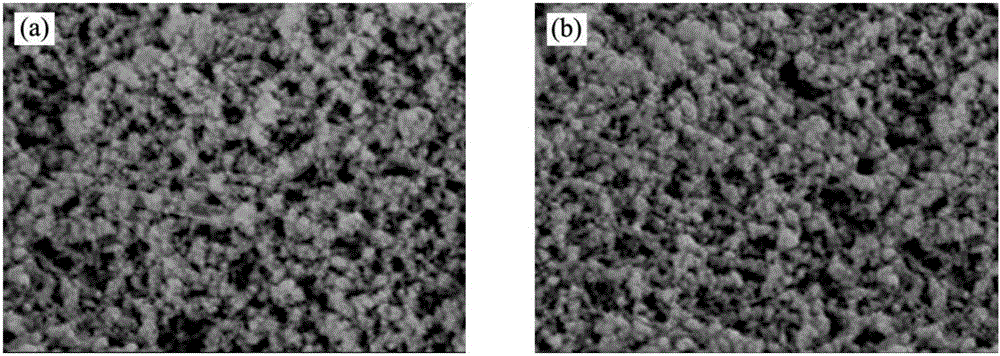

[0026] Add 0.1g12mol / L hydrochloric acid to 80g tetraethyl orthosilicate, stir at room temperature for 28min and then let it stand for 35min, then add 0.14 sodium hydroxide, stir until it is completely dissolved, and get the wet gel after standing the above solution for 2h. Add 0.2g methacryloyloxyethyl dodecyl dimethyl ammonium chloride to the gel, after standing for 6h, put the product in CO 2 In a supercritical high-pressure extraction device, CO 2 The medium is subjected to supercritical drying at a temperature of 33°C and an air pressure of 7 MPa for 3 hours to obtain silica airgel. Add 10 g of silica airgel to 100 g of methyl methacrylate, and then perform ultrasonic dispersion for 1 hour. Then add 0.2 g of dibenzoyl peroxide, ultrasonically disperse for 10 minutes, and then place the dispersion in a water bath at 75°C to trigger methyl methacrylate and methacryloyloxyethyl on the surface of the silica airgel. Copolymerize dialkyl dimethyl ammonium chloride, take it out...

Embodiment 2

[0028] Add 0.8g of 12mol / L hydrochloric acid to 110g of ethyl orthosilicate, stir at room temperature for 30min and let it stand for 150min, then add 0.01sodium hydroxide, stir until it is completely dissolved, and get the wet gel after the above solution is left for 3h. Add 0.6g methacryloyloxyethyl dodecyl dimethyl ammonium chloride to the gel, after standing for 3h, put the product in CO 2 In a supercritical high-pressure extraction device, CO 2 The medium is subjected to supercritical drying at a temperature of 46°C and an air pressure of 8 MPa for 3 hours to obtain silica airgel. Add 5 g of silica airgel to 100 g of methyl methacrylate, and then perform ultrasonic dispersion for 1 hour. Then add 0.02 g of dibenzoyl peroxide, ultrasonically disperse for 3 minutes, and then place the dispersion liquid in a water bath at 75°C to trigger methyl methacrylate and methacryloyloxyethyl on the surface of the silica airgel. Copolymerize dialkyl dimethyl ammonium chloride, take it ...

Embodiment 3

[0030] Add 0.2g of 12mol / L hydrochloric acid to 150g of ethyl orthosilicate, stir at room temperature for 5 minutes and let it stand for 180 minutes, then add 0.16 sodium hydroxide, stir until it is completely dissolved, and leave the above solution for 6 hours to obtain a wet gel. Add 0.7g methacryloyloxyethyl dodecyl dimethyl ammonium chloride to the gel, after standing for 5h, put the product in CO 2 In a supercritical high-pressure extraction device, CO 2 The medium is subjected to supercritical drying at a temperature of 50°C and an air pressure of 9 MPa for 3 hours to obtain silica airgel. Add 7 g of silica airgel to 100 g of methyl methacrylate, and then perform ultrasonic dispersion for 1 hour. Then add 0.14g of dibenzoyl peroxide, ultrasonically disperse for 4.8min, and then place the dispersion in a water bath at 75°C to trigger methyl methacrylate and methacryloyloxyethyl on the surface of the silica airgel. Copolymerize dodecyldimethylammonium chloride, take it ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com