Nanotechnology protection method for existing bridge structures

A bridge structure and nanotechnology technology, applied in bridges, bridge materials, bridge maintenance, etc., can solve the problems of ineffective protection of concrete, inability to protect concrete, and achieve the effect of resisting ultraviolet radiation, enhancing protection hardness, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The specific preparation method of the nano-silicon coating is as follows: wherein, in the nano-coating, the total ratio of component A: component B is 3:1. In the specific operation, first pour in component A, then pour in component B and then stir evenly. After mixing, let it stand for 3 hours before painting. By brushing the concrete surface in step H and step I, the concrete surface is coated with two layers of nano-silicon paint, which has very good anti-corrosion performance, and can better prevent artificial graffiti on the surface, which affects the appearance.

[0053] Preferably, the construction conditions of epoxy mortar, epoxy varnish, epoxy topcoat and nano-silicon coating are: the relative humidity of the environment is below 85%, and the ambient temperature is greater than 5°C.

[0054] In the present invention, in step B to step H, prove through a large amount of experiments, preferably control the construction time interval of each step, preferably con...

Embodiment 1

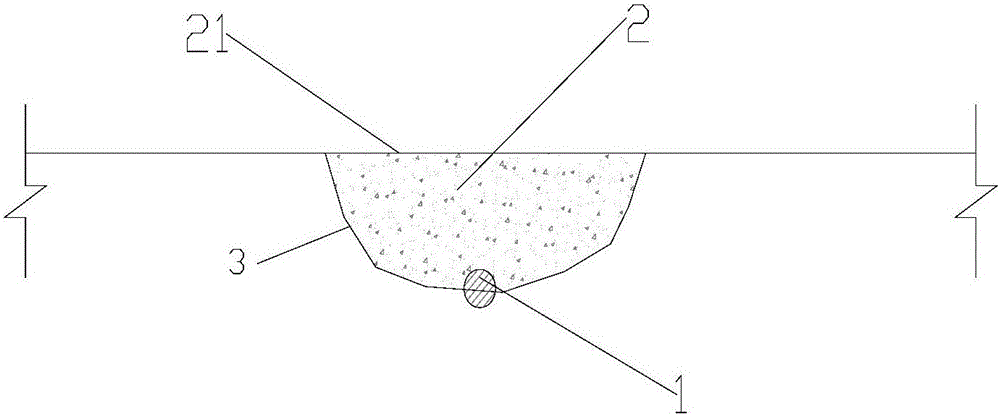

[0056] Please refer to figure 1 and figure 2 As shown, the specific application examples of the nanotechnology protection method of the current bridge structure.

[0057] First the loose concrete 3 on the surface of the existing bridge structure is chiseled out, and the exposed steel bar 1 is derusted, brushed with a rust inhibitor, and the epoxy mortar 2 prepared by the coarse sand of the present invention is repaired to the potholes chiseled out, After repairing, the concrete surface layer 21 is further repaired and leveled with epoxy mortar prepared with fine sand, and after the repairing and leveling is completed, the carbonized concrete on the surface layer is polished.

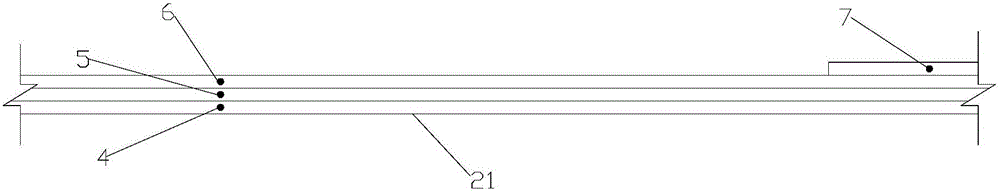

[0058] After the surface treatment, apply a layer of epoxy varnish 4 as a sealing primer, then further brush two layers of colored epoxy topcoat 5, and finally use nano-coating on the concrete surface to form the first nano-coating layer 6 , The second layer of nano-coating layer 7 is painted on the k...

Embodiment 2

[0060] Please refer to figure 2 As shown, the first coat of epoxy varnish 4 is applied on the surface of the concrete, the second coat of colored epoxy topcoat is applied 24 hours later, and the third coat of colored epoxy topcoat 5 is applied after 24 hours After 48 hours, the first layer of nano-coating layer 6 is applied, and after another 48 hours, the second layer of nano-coating layer 7 is partially applied to finally form a protective layer inside and on the surface of the concrete. This protective layer can effectively resist ultraviolet radiation, strengthen Protect hardness, improve acid and alkali resistance. Experiments prove that the construction method of the present invention has better protection effect. Compared with existing construction methods, it has better durability and more effectively protects the internal structure of concrete.

[0061] Nano coating of the present invention is SiO 2 Nanoparticles, using a two-component, the nanocoating based on Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com