Method for preparing perovskite thin film in perovskite solar cell via solution air extraction method

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the uniformity and crystallinity of the film cannot be effectively controlled, it is difficult to apply in industrialization, and the substrate is exposed, so as to facilitate industrialization and Continuous production, high repeat accuracy, uniform and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

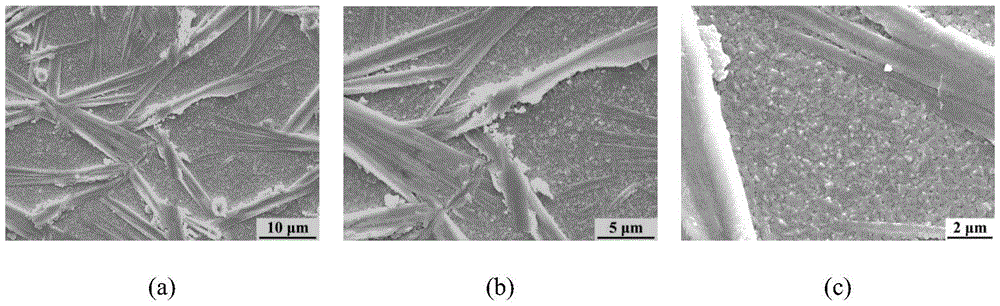

[0046] 1) With DMF as solvent, PbI 2 and CH 3 NH 3 I is the solute, and the perovskite solution is prepared, and the CH in the perovskite solution 3 NH 3 PB 3 The mass percentage concentration is 35%.

[0047] 2) A layer of prepared perovskite solution was sprayed on the flexible conductive substrate ITO by spraying method to obtain a layer of light yellow perovskite liquid film with a thickness of about 1500nm.

[0048] 3) Exhaust and dry at 50°C. At this temperature, the saturated vapor pressure of the solvent is about 2200Pa. The perovskite liquid film is placed in a chamber of 400Pa. At this time, the pressure difference between the solvent and the chamber pressure is 1800Pa. The solvent evaporates quickly, and the liquid film has a very high degree of supersaturation, which satisfies the conditions for nucleation, and the liquid film nucleates and grows heterogeneously on the rough substrate. The solvent evaporated within 30s, and the obtained film was taken out aft...

Embodiment 2

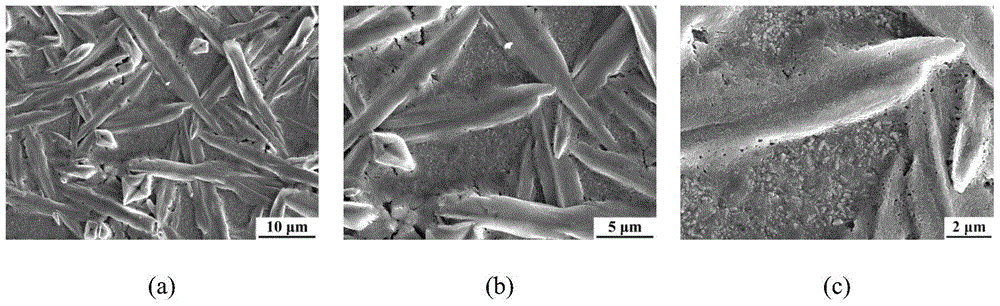

[0052] 1) With DMSO as solvent, PbI 2 and CH 3 NH 3 I is the solute, and the perovskite solution is prepared, and the CH in the perovskite solution 3 NH 3 PB 3 The mass percentage concentration is 30%.

[0053] 2) Scrape-coat a layer of prepared perovskite solution on the conductive glass FTO substrate to obtain a layer of light yellow perovskite liquid film with a thickness of about 2000nm.

[0054] 3) Air extraction and drying are carried out at 70°C. At this temperature, the saturated vapor pressure of the solvent is about 5900Pa. The perovskite liquid film is placed in a chamber of 40Pa. At this time, the pressure difference between the solvent and the chamber pressure is 5860Pa. After the solvent evaporates, the liquid film reaches supersaturation, and the liquid film nucleates and grows heterogeneously on the surface of the rough substrate. The solvent evaporated within 10s, and the film was taken out after 10s, and the color of the film was dark red.

[0055] 4) ...

Embodiment 3

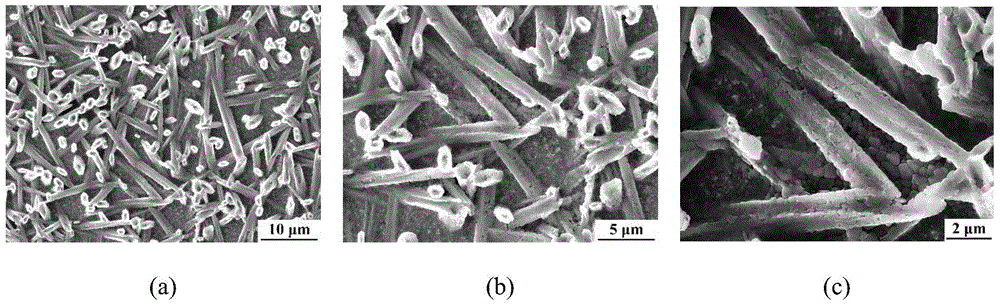

[0058] 1) With DMF as solvent, PbI 2 and CH 3 NH 3 I is the solute, and the perovskite solution is prepared, and the CH in the perovskite solution 3 NH 3 PB 3 The mass percentage concentration is 40%.

[0059] 2) Coating a layer of prepared perovskite solution on the conductive glass ITO substrate by coating method to obtain a layer of light yellow perovskite liquid film with a thickness of about 4000nm.

[0060] 3) Air extraction and drying are carried out at 25°C. At this temperature, the saturated vapor pressure of the solvent is about 550Pa. The perovskite liquid film is placed in a chamber of 500Pa. At this time, the pressure difference between the solvent and the chamber pressure is 50Pa. After the solvent evaporates, the liquid film reaches supersaturation, and the liquid film nucleates and grows heterogeneously on the surface of the rough substrate. The solvent evaporated within 60s, and the film was taken out after 60s, and the color of the film was dark red.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com