A kind of phosphorus-carbon composite material and its preparation method and application

A carbon composite material and composite material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low Coulomb efficiency, low capacity, and poor cycle stability in the first cycle, achieve excellent cycle stability, and alleviate volume expansion. , the effect of excellent contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

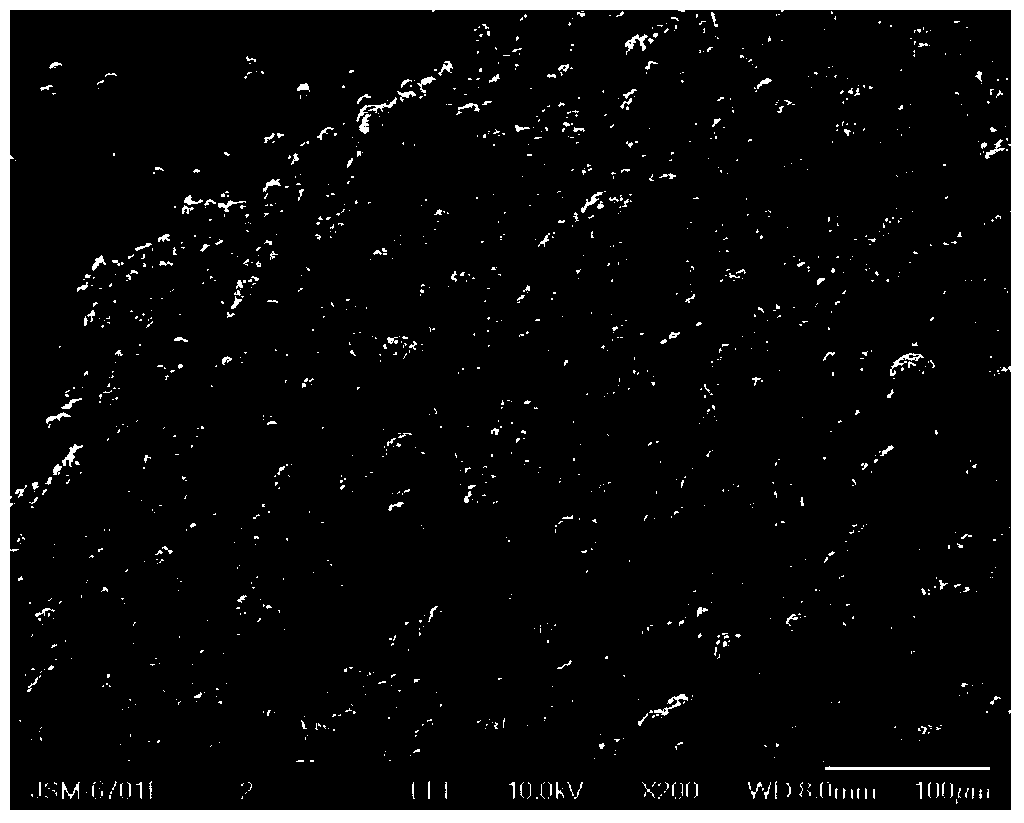

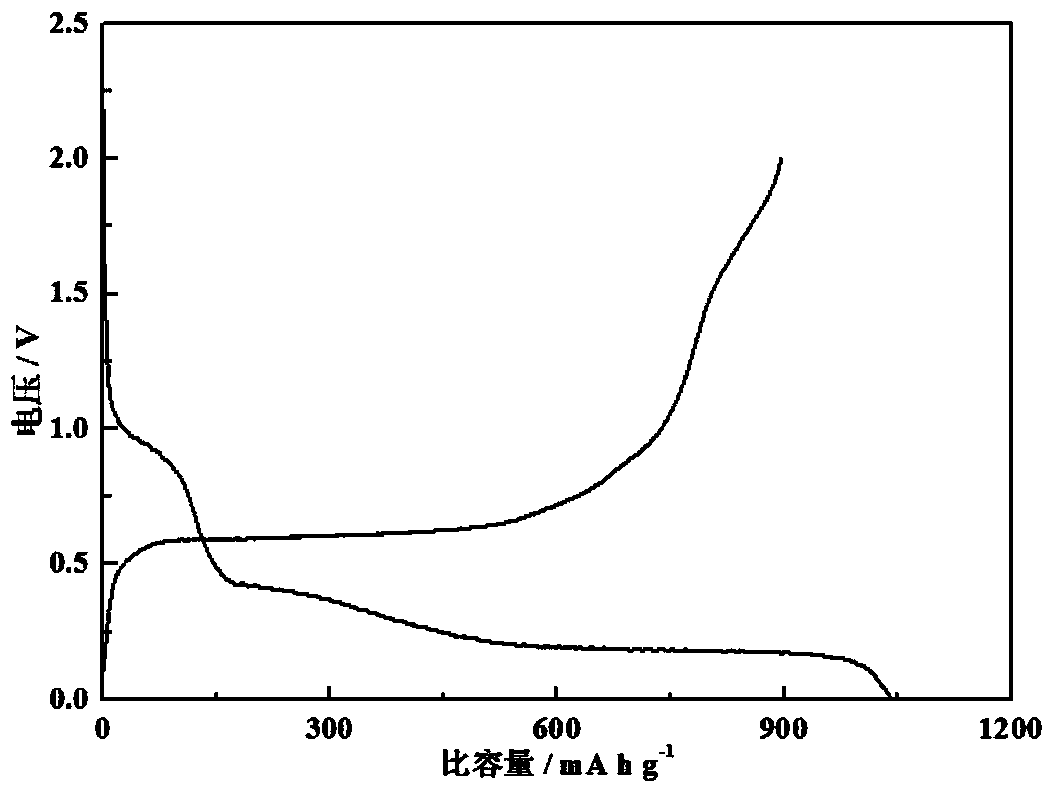

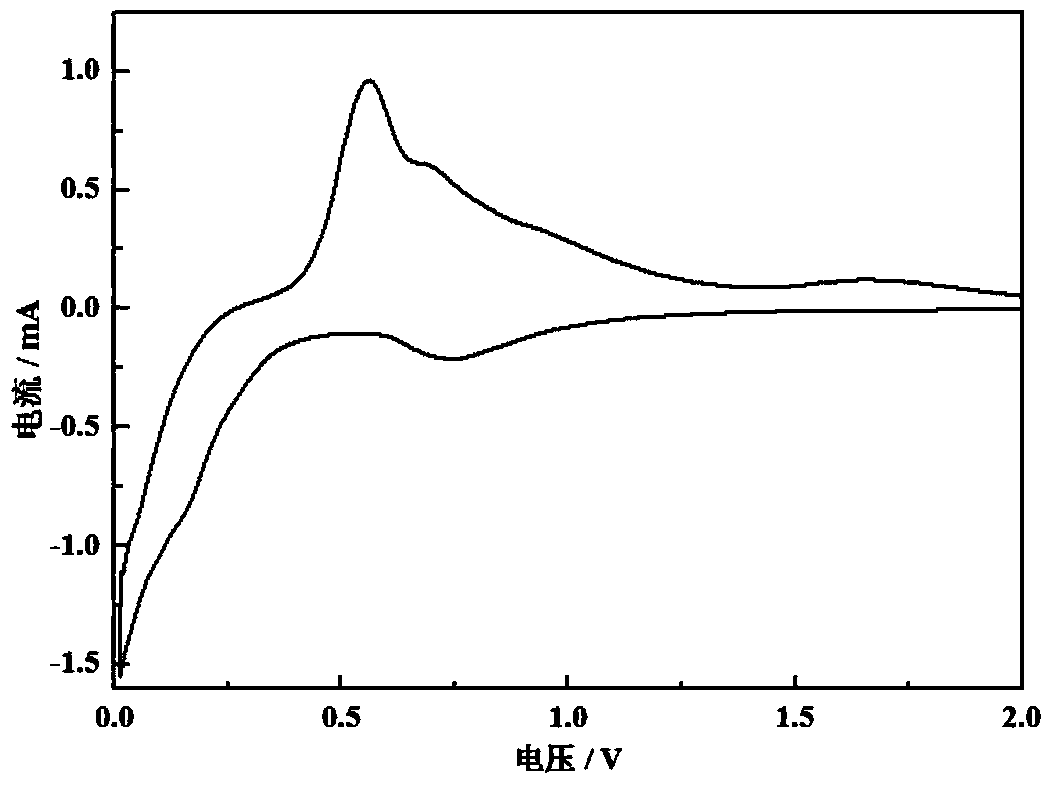

[0023] Mill micron red phosphorus with an average particle size of 5 μm, sodium alginate, and polyvinylpyrrolidone in an argon-protected ball mill for 24 hours. The frequency of the ball mill is 40 Hz. It is 10:1:1. Disperse graphite flakes and carbon nanotubes in an aqueous solution. The mass ratio of micron red phosphorus to graphite flakes and carbon nanotubes is 5:3.5:0.5. Add the dispersed graphite flake suspension into a ball mill tank and mill for 3 hours. The frequency is 25Hz. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 160°C, the outlet temperature is 100°C, and the airflow The temperature was 6 L / min, the feed rate was 25 r / min, and the obtained phosphorus-carbon composite material was dried at 180° C. in an argon atmosphere for 2 hours, and the temperature increase rate was 10° C. / min.

[0024] The phosphorus-carbon negative electrode material prepared...

Embodiment 2

[0027] Mill micron red phosphorus with an average particle size of 5 μm, sodium alginate, and polyvinylpyrrolidone in an argon-protected ball mill for 24 hours. The frequency of the ball mill is 40 Hz. It is 10:0.5:0.5. Disperse graphite flakes and carbon nanotubes in an aqueous solution. The mass ratio of micron red phosphorus to graphite flakes and carbon nanotubes is 5:4:0.5. Add the dispersed graphite flake suspension into a ball mill tank and mill for 3 hours. The frequency is 25Hz. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 160°C, the outlet temperature is 100°C, and the airflow The temperature was 6 L / min, the feed rate was 25 r / min, and the obtained phosphorus-carbon composite material was dried at 180° C. in an argon atmosphere for 2 hours, and the temperature increase rate was 10° C. / min.

[0028] The test method is the same as in Example 1, and the bat...

Embodiment 3

[0030] Mill micron red phosphorus with an average particle size of 5 μm, sodium alginate, and polyvinylpyrrolidone in an argon-protected ball mill for 24 hours. The frequency of the ball mill is 40 Hz. It is 10:1.5:1.5. Disperse graphite flakes and carbon nanotubes in an aqueous solution. The mass ratio of micron red phosphorus to graphite flakes and carbon nanotubes is 5:3:0.5. Add the dispersed graphite flake suspension into a ball mill tank and mill for 3 hours. The frequency is 25Hz. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 160°C, the outlet temperature is 100°C, and the airflow The temperature was 6 L / min, the feed rate was 25 r / min, and the obtained phosphorus-carbon composite material was dried at 180° C. in an argon atmosphere for 2 hours, and the temperature increase rate was 10° C. / min.

[0031]The test method is the same as in Example 1, and the batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com