Preparation method of silage

A technology of silage and corn stalks, which is applied to the preservation method of animal feed raw materials, animal feed, animal feed, etc., can solve the problems of easy drug resistance, slow pH drop of silage, and single raw materials, so as to prevent and control livestock Effects of common diseases, reduction of heavy use, and improvement of production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

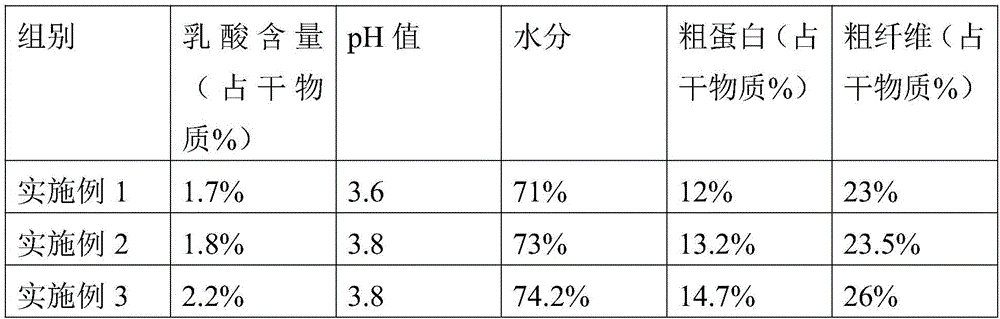

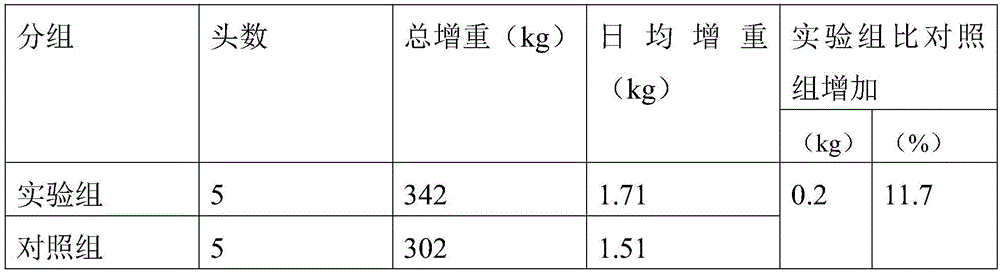

Embodiment 1

[0022] A method for preparing silage, the method comprising the steps of:

[0023] (1) Preparation of major ingredients: get corn stalks and alfalfa in the air, so that the water content of corn stalks is 75-80%; the water content of the alfalfa is 62-68%; then corn stalks and alfalfa are shredded for subsequent use; The number of parts, weighing 70 parts of corn stalks, 20 parts of alfalfa, 10 parts of bran, 8 parts of fermented soybean meal; 3 parts of corn flour, 0.5 parts of medical stone;

[0024] (2) Add fermentation accelerator, protective agent and nutritional additive to the main ingredient; Mix to obtain the first product; Wherein, the mass ratio of the main ingredient to the fermentation accelerator, protective agent and nutritional additive is 100: 5:2:2; the fermentation accelerator is composed of sweet potato flour, amylase and lactic acid bacteria; wherein the mass ratio of sweet potato flour and amylase is 1:1.5; the mass ratio of main ingredient to sweet potat...

Embodiment 2

[0028] A method for preparing silage, the method comprising the steps of:

[0029] (1) Preparation of major ingredients: get corn stalks and alfalfa in the air, so that the water content of corn stalks is 75-80%; the water content of the alfalfa is 62-68%; then corn stalks and alfalfa are shredded for subsequent use; The number of parts, weighing 65 parts of corn stalks, 15 parts of alfalfa, 10 parts of bran, 5 parts of fermented soybean meal; 2 parts of corn flour, 0.2 parts of medical stone;

[0030] (2) Add fermentation accelerator, protective agent and nutritional additive to the main ingredient; Mix to obtain the first product; Wherein, the mass ratio of the main ingredient to the fermentation accelerator, protective agent and nutritional additive is 100: 5:2:2; the fermentation accelerator is composed of sweet potato flour, amylase and lactic acid bacteria; wherein the mass ratio of sweet potato flour and amylase is 1:1.5; the mass ratio of main ingredient to sweet potat...

Embodiment 3

[0034] A method for preparing silage, the method comprising the steps of:

[0035] (1) Preparation of major ingredients: get corn stalks and alfalfa in the air, so that the water content of corn stalks is 75-80%; the water content of the alfalfa is 62-68%; then corn stalks and alfalfa are shredded for subsequent use; The number of parts, weighing 88 parts of corn stalks, 30 parts of alfalfa, 20 parts of bran, 10 parts of fermented soybean meal; 5 parts of corn flour, 1 part of medical stone;

[0036] (2) Add fermentation accelerator, protective agent and nutritional additive to the main ingredient; Mix to obtain the first product; Wherein, the mass ratio of the main ingredient to the fermentation accelerator, protective agent and nutritional additive is 100: 5:2:2; the fermentation accelerator is composed of sweet potato flour, amylase and lactic acid bacteria; wherein the mass ratio of sweet potato flour and amylase is 1:1.5; the mass ratio of main ingredient to sweet potato ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com