Ultrasonic responsive bone repair material, production method and use thereof

A manufacturing method and bone repair technology, applied in the field of biomedical engineering, can solve problems such as limited light penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

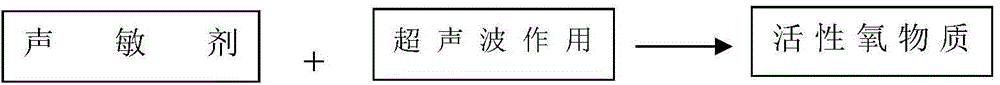

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

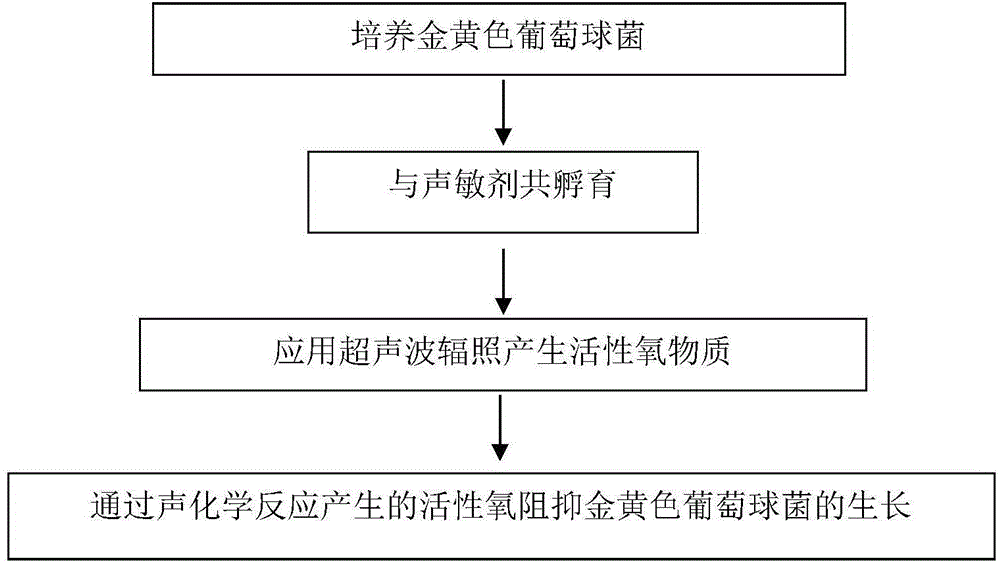

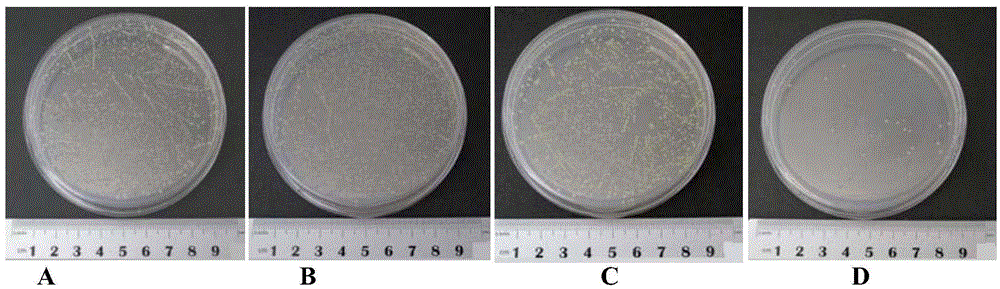

[0029] Example 1: Observation of the killing effect of the sound-sensitizer on Staphylococcus aureus under the action of ultrasonic waves on bacteria cultured in vitro: culture target bacteria: select Staphylococcus aureus, and routinely cultivate it in an incubator containing 5% carbon dioxide and saturated water vapor at 37°C middle; then, the target bacteria in the logarithmic growth phase (1×10 6 cfu / ml), adding a sonosensitizer such as chlorine6 and incubating for 15 minutes at 37°C in an incubator containing 5% carbon dioxide and saturated water vapor, because some sonosensitizer chloride6 may not be phagocytized by the target bacteria, and is still free in the In the culture solution, so before the ultrasonic action, wash several times to remove the residual chloride6 in the culture solution; then, apply ultrasonic (frequency is 1.0MHz, sound intensity is 1.56W / cm 2 ) to irradiate the target bacteria. Under the action of ultrasonic waves, the sonosensitizer chlorine6 u...

Embodiment 2

[0031] Example 2: Pour the sonic sensitizer hypocrellin into absolute ethanol, mix well, then filter and exhaust to make a hypocrellin solution; then, put bone repair materials in the hypocrenin solution Take it out after dipping for 10 seconds to 4 hours; dry it with nitrogen; repeat the above steps 1-3 times, and finally dry it with nitrogen to obtain an ultrasound-responsive bone repair material.

[0032] In this embodiment 2, the selected sound sensitizer is a safe and non-toxic sound sensitizer that can generate active oxygen species under the action of ultrasonic waves. In addition to hypocretin, it can also be aluminum phthalocyanine, 5- Aminolevulinic acid, monoasparagine chlorin, dexamethorphyrin lutetium, rose bengal, hematoporphyrin, hematoporphyrin monomethyl ether, and the like.

Embodiment 3

[0033] Example 3: Add the sound sensitizer rose bengal (rosebengal) into polyaminoacid (polyamineacid) and stir thoroughly, then, apply the resulting liquid on the surface of the bone repair material; dry it naturally or blow it dry with nitrogen to obtain an ultrasonic response material for bone repair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com