A kind of low-carbon alkane isomerization catalyst and preparation method thereof

A technology of low-carbon alkanes and catalysts, which is applied in the field of low-carbon alkanes isomerization catalysts and their preparation, can solve problems such as poor activity and diffusion performance, reduced effective utilization of molecular sieves, and influence on catalyst selectivity and stability. Discharge of difficult-to-treat wastewater, small active particles, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

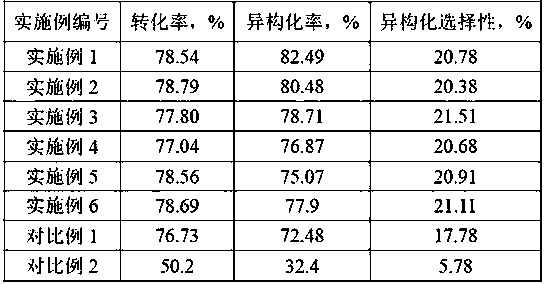

Examples

Embodiment 1

[0023] A kind of preparation step of catalyst of the present invention is as follows:

[0024] (1) Dissolve chloroplatinic acid containing 1 gram of platinum in 14 grams of water, and 19 grams of ZSM-35 molecular sieve (0.5 microns in particle size, SiO 2 / Al 2 o 3 The molar ratio is 25) and the above solution is fully mixed, and the mixture is dried at 120°C for 16 hours and calcined at 480°C for 4 hours to obtain platinum-loaded ZSM-35 molecular sieves;

[0025] (2) Dissolve 90 grams of water-soluble cornstarch (molecular weight: 35,000) in 300 grams of water, then add 10 grams of the molecular sieve obtained in step (1) at room temperature, fully stir into a uniform suspension, and vacuum spray dry (vacuum The temperature is 0.03MPa, the drying temperature is 60°C, and the drying time is 5h), and a starch-embedded molecular sieve with an average particle diameter of 80 microns is obtained.

[0026] (3) Mix 20 grams of the starch-embedded molecular sieve prepared in step ...

Embodiment 2

[0029] An embodiment of the catalyst of the present invention is the same as in Example 1, except that the substance content in each step is adjusted, the mass ratio of starch to molecular sieve is 5:1, and the starch-embedded molecular sieve with an average particle diameter of 50 microns is prepared. . The composition of the obtained catalyst is Pt: 0.02%, ZSM-35: 4.0%, alumina: the balance. The evaluation results are shown in Table 1.

Embodiment 3

[0031] An embodiment of the catalyst of the present invention is the same as in Example 1, except that palladium chloride is used to replace chloroplatinic acid in step (1), and the substance content in each step is adjusted, and the mass ratio of starch to molecular sieve is 2:1 , prepared a starch-embedded molecular sieve with an average particle diameter of 70 microns, and obtained a catalyst composition, which was Pd: 0.5%, ZSM-35: 0.8%, and alumina: the balance. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com