A kind of preparation method of porous hollow gold-silver nano-alloy particles

A technology of alloy particles and silver nanometers, applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of poor technical stability, particle LSPR cannot fully absorb SERS signal and poor reproducibility, and achieve simple preparation method and excellent SERS Enhanced effect, long-term stable storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

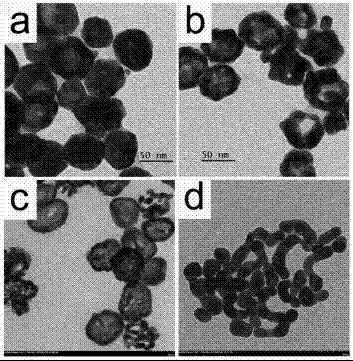

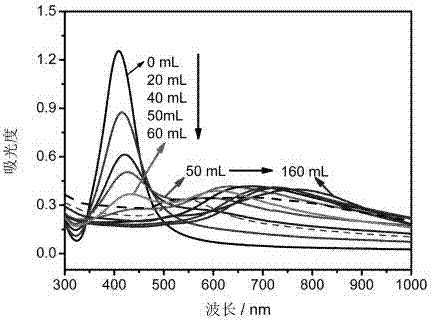

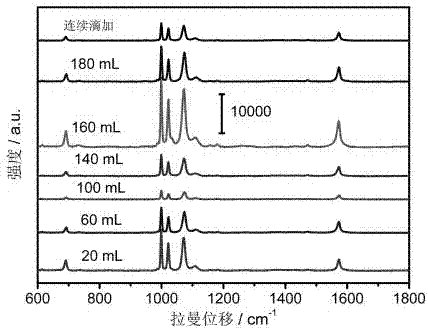

[0031] Preparation of silver nanoparticles: Add 200mL triple distilled water to a three-neck flask and heat to 70°C, then add 36mg of silver nitrate, and continue heating until the solution is in a slightly boiling state, then quickly add 4mL of sodium citrate aqueous solution with a concentration of 30mg / mL, at 95°C The reaction was carried out at low temperature for 8 minutes, and then the temperature was maintained at 85-90° C. for 60 minutes to prepare monodisperse silver nanoparticles with a particle size of about 30-40 nm. Adjust the reaction temperature to 60°C, 70°C, 80°C, and 90°C, and add 20 mL every 30 minutes to a concentration of 1.0×10 -4 mol / L chloroauric acid aqueous solution to 160mL. The SPR and Raman enhancement of the obtained alloy nanoparticles were tested respectively.

Embodiment 5

[0033] Add 200mL of triple distilled water into the three-necked flask and heat it to 70°C, then add 36mg of silver nitrate, and continue to heat until the solution is in a slightly boiling state, then quickly add 4mL of sodium citrate aqueous solution with a concentration of 30mg / mL, react at 95°C for 8 minutes, Then maintain the temperature at 85-90° C. for 60 minutes to prepare monodisperse silver nanoparticles with a particle size of about 30-40 nm. Adjust the reaction temperature to 70°C, add 20 mL every 30 minutes with a concentration of 1.0×10 -4 mol / L chloroauric acid aqueous solution to 240mL. Samples were taken at every 20mL injection interval and tested for SPR and Raman enhancement of the product under different volume addition conditions.

Embodiment 6

[0035] Add 200mL of triple distilled water into the three-necked flask and heat it to 70°C, then add 36mg of silver nitrate, and continue to heat until the solution is in a slightly boiling state, then quickly add 4mL of sodium citrate aqueous solution with a concentration of 30mg / mL, react at 95°C for 8 minutes, Then maintain the temperature at 85-90° C. for 60 minutes to prepare monodisperse silver nanoparticles with a particle size of about 30-40 nm. Adjust the reaction temperature to 70°C, and continuously add the concentration of 1.0×10 -4 mol / L chloroauric acid aqueous solution to 160mL. Samples were taken and tested for SPR and Raman enhancement of the product at different sample volumes.

[0036] The hollow gold-silver nano-alloy particles prepared in Examples 1-6 were used as the substrate, and the excitation wavelength was 785nm. Under the same detection conditions, thiophenol was used as the probe molecule to test its SERS enhancement effect.

[0037] For the conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com