Method for preparing sulfate-resistant polycarboxylate water-reducing agents and application thereof

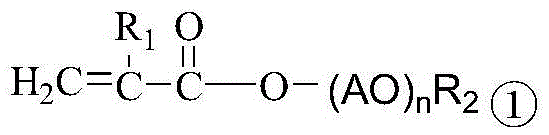

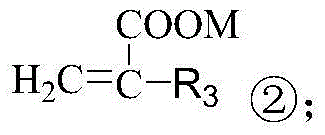

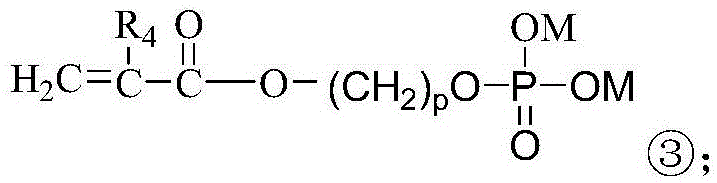

A technology of sulfate polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of insufficient water reducing effect, poor adaptability, poor sulfate resistance, etc., and achieves low slump loss, low production cost, cement good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Combine 15.6g polyethylene glycol monomethyl ether methacrylate (Mn=500g / mol), 0.67g 4-cyano-4-(phenylthioformylthio)pentanoic acid and 0.06g azobisisobutyl Glyamidine hydrochloride and 36.4g of water are thoroughly mixed, and then N 2 Put O in solution 2 Discharge at N 2 The reversible addition-fragmentation chain transfer polymerization reaction is carried out under protection. The reaction temperature is 60℃, the reaction time is 9h, and the conversion rate of monomer a is 97.34%. The unreacted monomer and small molecules are removed by dialysis to obtain a large polyether monomer. Body-RAFT reagent (Mw=7.18kDa),

[0053] Adding 3.31 g acrylic acid (conversion rate 54.52%) and 9.67 g hydroxyethyl methacrylate phosphate (conversion rate 49.65%) to continue polymerization for 12 hours to obtain sulfate-resistant polycarboxylic acid water-reducing agent mother liquor (Mw=8.05kDa).

Embodiment 2

[0055] Combine 29.64g polyethylene glycol monomethyl ether acrylate (Mn=950g / mol), 0.28g 2-(phenylthioformylthio)propionic acid, 0.03g azobisisobutylamidine hydrochloride and 55g After the water is fully mixed, pass in N 2 Put O in solution 2 Discharge at N 2 The reversible addition-fragmentation chain transfer polymerization reaction is carried out under protection. The reaction temperature is 65℃, the reaction time is 8h, and the conversion rate of monomer a is 97.83%. The unreacted monomer and small molecules are removed by dialysis to obtain a large polyether monomer. Body-RAFT reagent (Mw=13.76kDa),

[0056] 37.49g of methacrylic acid (conversion rate of 60.46%) and 21.37g of hydroxyethyl acrylate phosphate (conversion rate of 56.37%) were added and polymerization was continued for 8 hours to obtain a sulfate-resistant polycarboxylic acid water-reducing agent mother liquor (Mw=31.09kDa).

Embodiment 3

[0058] Combine 29.64g polyethylene glycol monomethyl ether methacrylate (Mn=950g / mol), 0.17g 4-cyano-4-(phenylthioformylthio)pentanoic acid and 0.01g 4,4'-coupling Nitrobis(4-cyanovaleric acid) and 55g of water are thoroughly mixed, then pass in N 2 Put O in solution 2 Discharge at N 2 The reversible addition-fragmentation chain transfer polymerization reaction is carried out under protection. The reaction temperature is 70℃, the reaction time is 8h, and the conversion rate of monomer a is 97.34%. The unreacted monomer and small molecules are removed by dialysis to obtain a large polyether monomer. Body-RAFT reagent (Mw=28.73kDa),

[0059] 37.17g acrylic acid (conversion rate 50.95%) and 49.59g hydroxypropyl methacrylate phosphate (conversion rate 53.39%) were added to polymerize for 7 hours to obtain a sulfate-resistant polycarboxylic acid water reducing agent mother liquor (Mw=43.36kDa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com